Gorman-Rupp Pumps 4D-B 461594 and up User Manual

Page 8

D SERIES

OM--01505

PAGE B -- 3

INSTALLATION

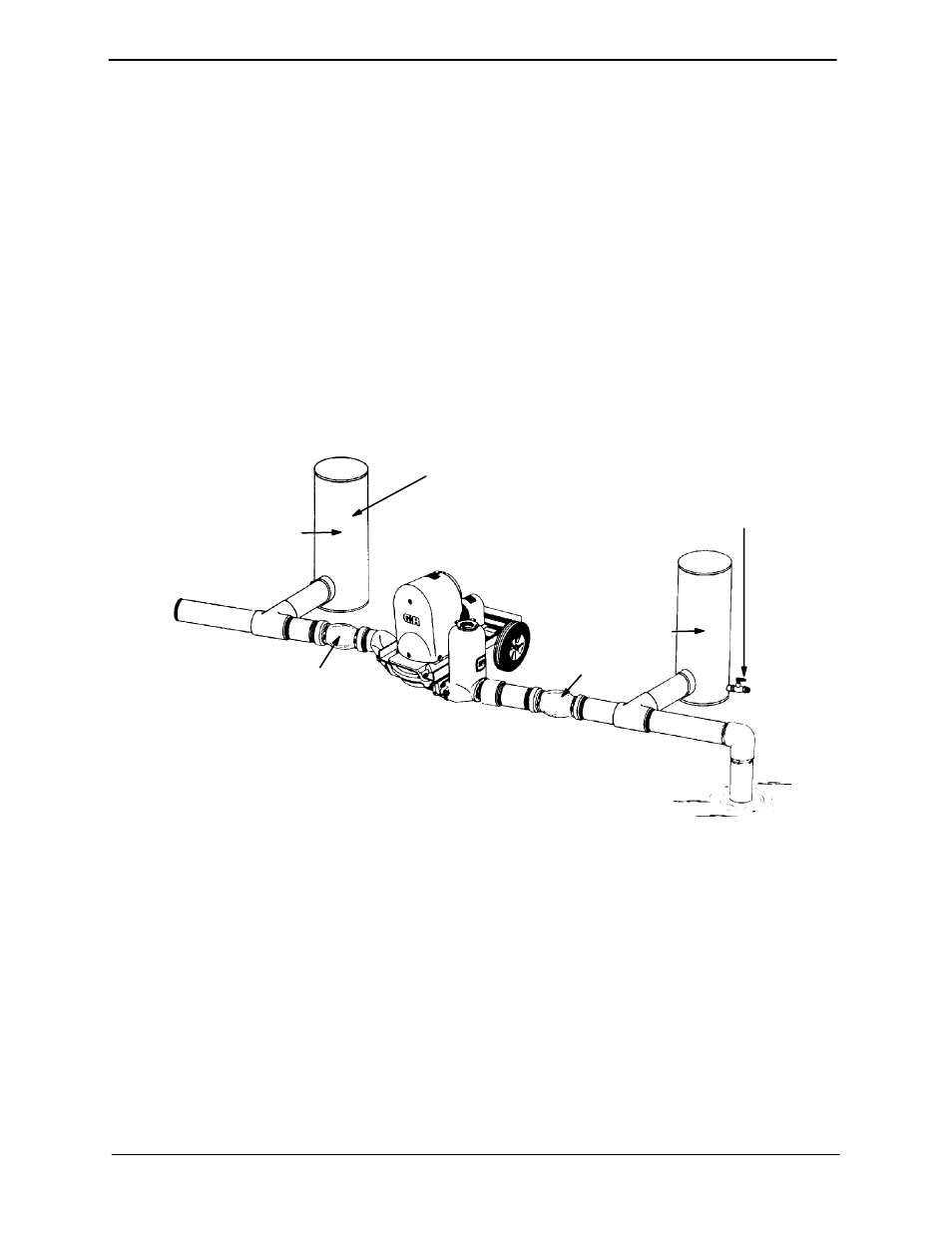

Fixed, Rigid Piping

This pump is equipped with an integral suction ac-

cumulator chamber which promotes an efficient

flow of liquid and acts as an air cushion against

shock. Since the air in this chamber will leak away

during pump operation, the air must be replen-

ished periodically. To introduce air into the cham-

ber, stop the pump and remove the suction accu-

mulator plug and integral gasket; this will break

prime and allow the liquid in the chamber to drain

away through the suction line.

If the pump is mounted in a system with fixed, rigid

piping, it is recommended that a flexible connec-

tion be installed at or near the suction and dis-

charge ports to absorb shock which would other-

wise be transmitted through the drive train and

greatly accelerate pump wear.

In a fixed piping installation, properly sized surge

suppressors

must be installed in both suction and

discharge lines. If commercial surge suppressors

are not readily available, air chambers may be fab-

ricated from pipe as shown in Figure 2.

AIR CHAMBERS

(18 TO 24 INCH LENGTHS OF

6 TO 8 INCH DIAMETER PIPE

WITH WELDED CAPS)

DISCHARGE

CHAMBER

DISCHARGE

FLEXIBLE JOINT

FLEXIBLE JOINT

SUCTION

CHAMBER

1/2-INCH VALVE FOR

RECHARGING AIR

CHAMBER WITH

COMPRESSED AIR

(ALSO ON DISCHARGE

CHAMBER)

SUCTION

NOTE: INSTALL AIR CHAMBERS OFF FLOW LINE TEES

TO AVOID SURFACE TURBULENCE WITHIN CHAMBERS.

Figure 2. Fixed Piping Installation

Note that the air chambers have not been installed

directly in the flow line, but have been installed off

tees to avoid turbulence within the chambers. The

air chambers are fitted with valves to permit intro-

duction of small amounts of compressed air to fur-

ther dampen shock; this compressed air will leak

away during operation, and should be replaced

from time to time. If the suction chamber floods,

open the suction chamber valve to break prime

and allow the liquid in chamber to drain through

the suction line.

Gauges

If discharge pressure and vacuum suction gauges

are desired, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installation closer to the pump may result in erratic

readings.