Gorman-Rupp Pumps T6A71S-B /F,/FM User Manual

Page 36

OM-05351

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 14

Reach through the back cover opening with the

check valve and position the check valve adaptor

in the mounting slot in the suction flange (21). Align

the adaptor with the flange hole and secure the as

sembly with the check valve pin (22).

NOTE

If the suction or discharge flanges were removed,

replace the respective gaskets, apply `Permatex

Aviation No. 3 Form‐A‐Gasket' or equivalent com

pound to the mating surfaces, and secure them to

the pump casing with the attaching hardware.

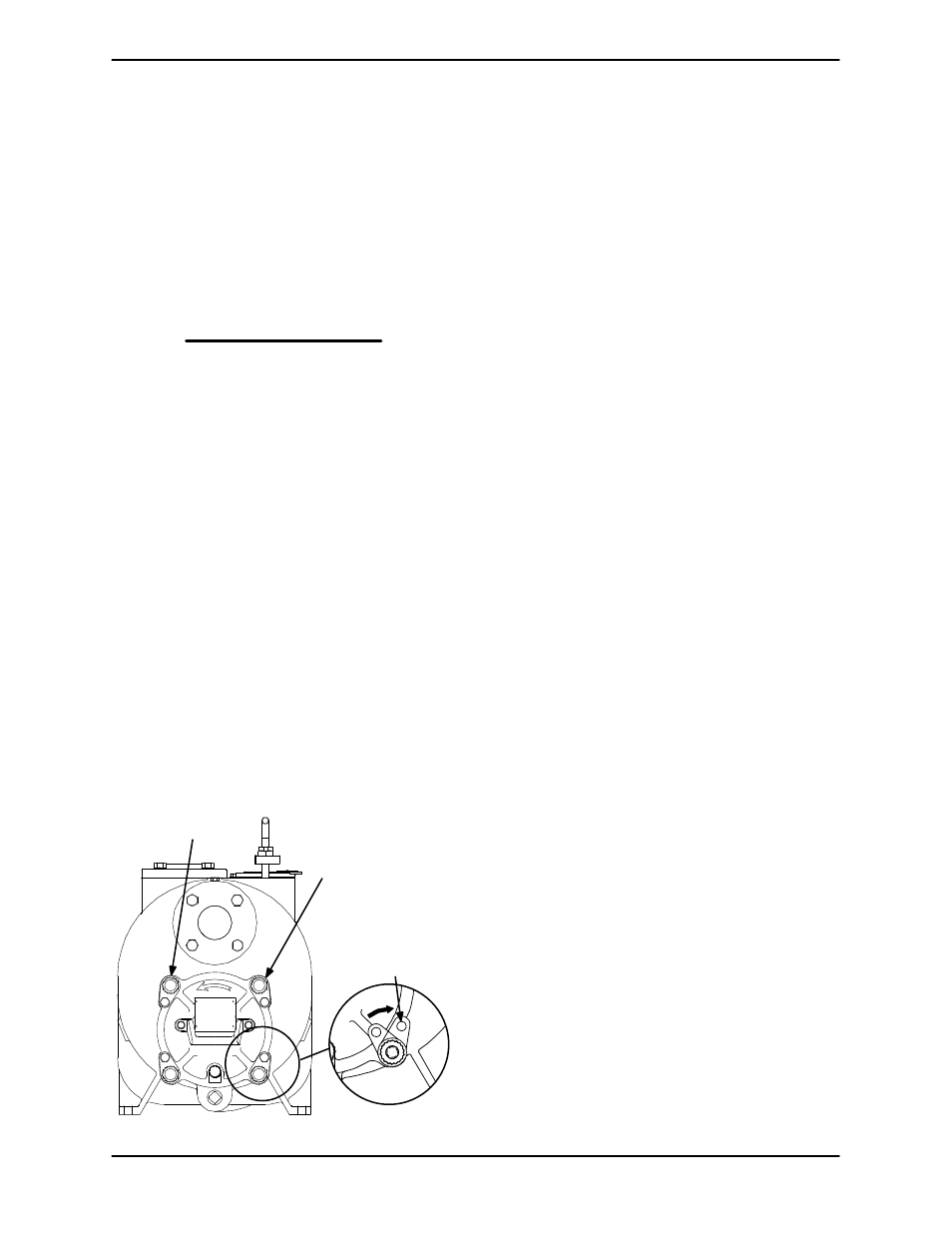

Back Cover Installation And Adjustment

(Figures 1 and 8)

If the wear plate (5) was removed for replacement,

carefully center the new wear plate on the back

cover and secure it with the hardware (7 and 8).

The wear plate must be concentric to prevent bind

ing when the back cover is installed.

Clearance between the impeller and wear plate is

adjusted using four adjusting screws and locking

collars. There are 18 detents on the I.D. of each

locking collar. Indexing the collars one detent on

the adjusting screws represents approximately

.005 inch (0,13 mm) of wear plate clearance. The

recommended clearance between the wear plate

and the impeller is .010 to .020 inch (0,25 to 0,50

mm).

USE TWO

OPPOSING

BACK COVER NUTS

TO PRESS

BACK COVER

INTO PUMP

CASING

USE TWO REMAINING

ADJUSTING SCREWS AND

LOCKING COLLARS TO

SET FACE CLEARANCE

INDEX COLLARS 3

DETENTS COUNTER‐

CLOCKWISE, THEN

TURN CLOCKWISE

UNTIL SCREW

HOLES ALIGN

Figure 8. Installing and Adjusting Back Cover

Replace the back cover O‐rings (6 and 9) and lubri

cate them with a generous amount of No. 2 grease.

Clean any scale or debris from the contacting sur

faces in the pump casing that might interfere or

prevent a good seal with the back cover.

Screw the four adjusting screws (11) into the

tapped holes in the back cover plate until they are

just flush with the machined surface on the back

side of the cover plate.

Align the back cover plate over the studs (3) and

slide it into the pump casing. Use two back cover

nuts (13) on diagonally opposing studs to press

the back cover into the pump casing until the wear

plate just touches the impeller when the shaft is

turned by hand. Tighten the hand nuts evenly to

avoid binding.

With the wear plate just touching the impeller, turn

the two free adjusting screws until they engage the

pump casing. Position the locking collars over the

adjusting screws so the holes in the collars for the

locking screws align approximately with the holes

in the cover plate.

Loosen the hand nuts used to press the back cover

into the pump casing one full turn.

Pull the collars off the adjusting screws, index them

three detents counterclockwise, and reinstall the

collars on the adjusting screws. Use the collars to

turn the adjusting screws clockwise until the holes

in the locking collars realign with the tapped screw

holes in the back cover plate. Secure the locking

collars to the back cover plate with the hardware

(14 and 15). Install the two remaining back cover

nuts snugly against the adjusting screws.

Remove the first two back cover nuts from their

studs. Turn the adjusting screws clockwise until

they engage the pump casing. Install the locking

collars and hardware (28 and 29). Reinstall the

back cover nuts.

Be sure the wear plate does not scrape against the

impeller.

Over time it may be necessary to repeat the adjust

ment process to compensate for normal wear be

tween the impeller and wear plate. When all of the

adjustment has been used on the back cover side

of the pump, an additional 0.125 inch (3,2 mm) of

adjustment may be obtained by removing the ro

tating assembly adjusting shims (33).