Gorman-Rupp Pumps T10A3S-B /FM,/WW User Manual

Page 29

OM-05290

SUPER T SERIES

MAINTENANCE & REPAIR

PAGE E - 8

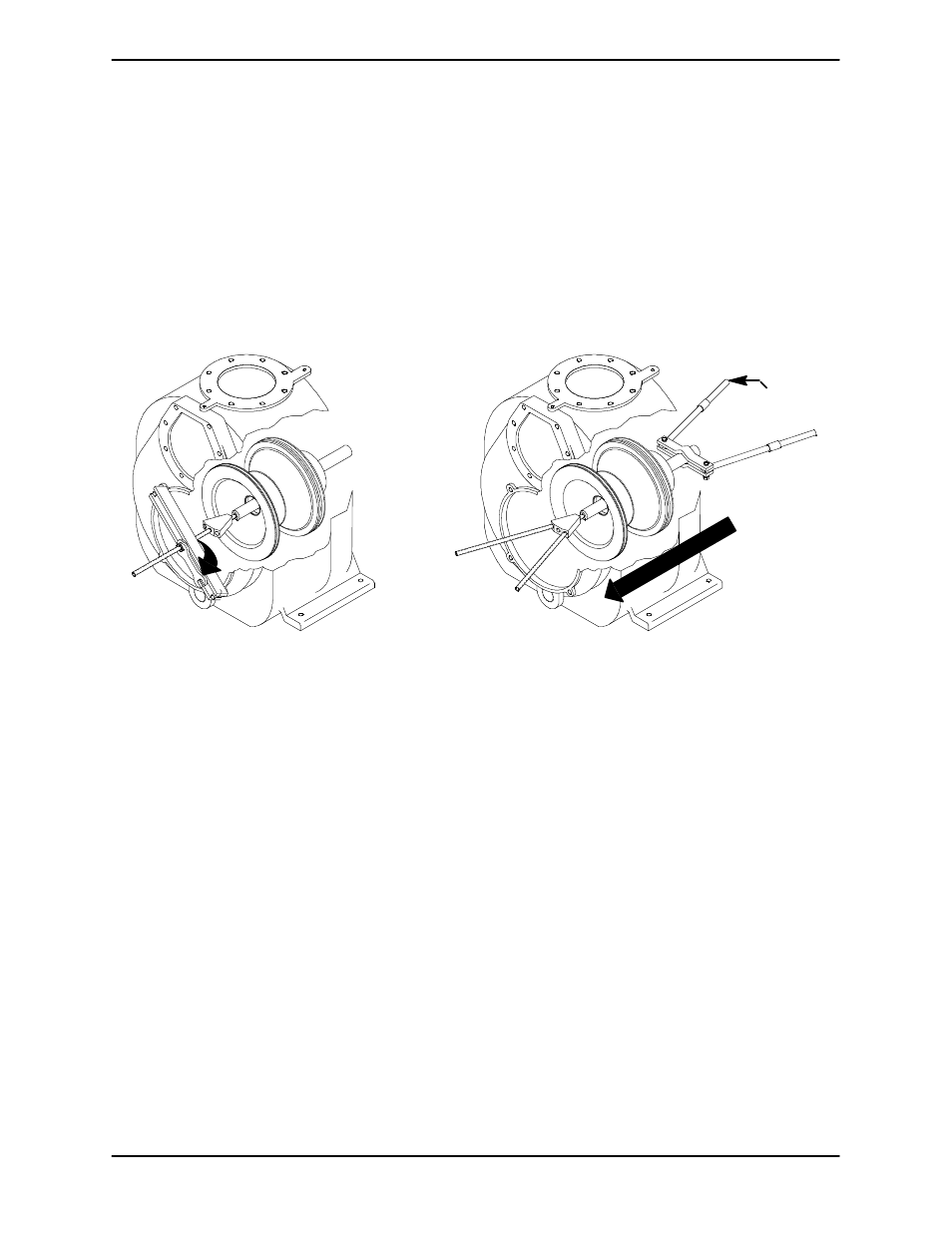

E‐3 for removal tool use). If the removal tool is not

used, install three of the inner capscrews in the

jacking holes in the casing ring, and use them to

press the rotating assembly into the pump casing

until the bearing housing is free.

Remove the jacking screws from the casing ring.

Remove the outer hardware (23 and 24) and shim

sets (21). Separate the casing ring from the pump

casing. Tie and tag the shim sets for ease of reas

sembly.

After the rotating assembly is loosened, screw a

5/8‐11 UNC X 16 inch long threaded rod into the

hole in the impeller shaft. Support the drive end of

the shaft with a 1‐13/16” (46 mm) minimum I.D.

piece of pipe or a set of handles as shown in Figure

E‐4, and slide the complete rotating assembly

through the suction head opening. Once free, use

a suitable hoist and sling and attach it to the lifting

eye provided at the top of the bearing housing to

move the rotating assembly to a suitable work area

for further disassembly.

ADD PIPE

AS REQUIRED

Figure E‐4. Rotating Assembly Removal With Tool

Impeller Removal

(Figure E‐2)

Unscrew the impeller from the shaft in a counter

clockwise direction (when facing the impeller). Use

caution when unscrewing the impeller; tension on

the shaft seal spring will be released as the impeller

is removed.

Remove the impeller adjusting shims (34). Tie and

tag the shims or measure and record their thick

ness for ease of reassembly.

Seal Removal And Disassembly

(Figure E‐2)

Slide the integral shaft sleeve and rotating portion

of the seal off the shaft as a unit.

Use a pair of stiff wires with hooked ends to remove

the stationary element and seat.

An alternate method of removing the stationary

portion of the seal is to remove the hardware (6 and

7) and separate the seal plate (3) and gasket (4)

from the bearing housing (9). Remove the seal

plate O‐ring (37) and bearing housing O‐rings (5

and 38).

Position the seal plate on a flat surface with the im

peller side down. Use a wooden dowel or other

suitable tool to press on the back side of the sta

tionary seat until the seat, O‐rings, and stationary

element can be removed.

Inspect the wear plate assembly (26) for excessive

wear or scoring. If replacement is required, remove

the hardware (24 and 25) securing it to the seal

plate.

If no further disassembly is required, refer to Seal

Installation.