Gorman-Rupp Pumps 03J1-B 713013 and up User Manual

Page 30

0 SERIES

OM-01202

MAINTENANCE & REPAIR

PAGE E - 10

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

-

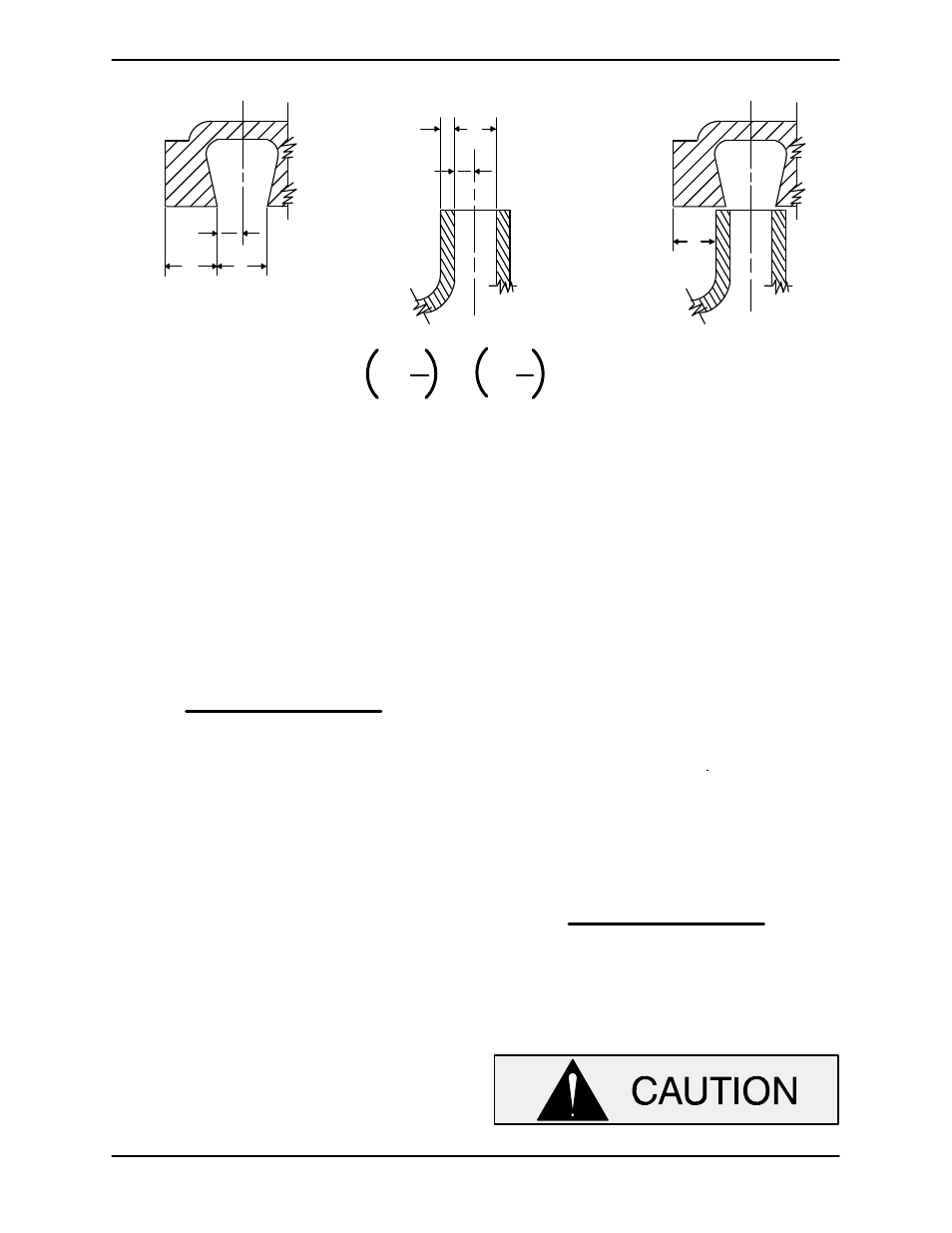

Figure 3. Centering Impeller Within Volute Scroll

Install the correct thickness of casing gaskets (5).

Remove the hardware temporarily securing the

seal plate to the pedestal. Secure the casing to the

seal plate and pedestal with the nuts (31). Reinstall

any leveling shims under the casing mounting feet,

and secure the casing to the base with the pre

viously removed hardware.

NOTE

After the pump casing has been installed, check for

free shaft rotation. Correct any scraping binding

before further reassembly.

Final Pump Assembly

Be sure the pump and power source are securely

mounted to the base.

Install the suction and discharge lines and open all

valves. Make certain that all piping connections are

tight, properly supported and secure.

Be sure the pump, pedestal and power source

have been properly lubricated, see LUBRICA

TION.

Fill the pump casing with clean liquid. Reinstall the

fill plug (49) and tighten it.

Refer to OPERATION, Section C, before putting

the pump back into service.

LUBRICATION

Seal Assembly

The seal assembly is lubricated by the medium be

ing pumped and no additional lubrication is re

quired.

Bearings

The pedestal was fully lubricated when shipped

from the factory. Check the oil level regularly

through the sight gauge (27)

and maintain it at the

middle of the gauge. When lubrication is required,

add SAE No. 30 non‐detergent

oil through the hole

for the air vent (15). Do not over‐lubricate. Over‐lu

brication can cause the bearings to over‐heat, re

sulting in premature bearing failure.

NOTE

The white reflector in the sight gauge must be posi

tioned horizontally to provide proper drainage.

Under normal conditions, drain the bearing hous

ing once each year and refill with clean oil. Change

the oil more frequently if the pump is operated con

tinuously or installed in an environment with rapid

temperature change.

Monitor the condition of the bearing lubri