Gorman-Rupp Pumps 82D2-B 344003 and up User Manual

Page 26

OM−00802

80 SERIES

MAINTENANCE & REPAIR

PAGE E − 8

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non-oil based solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leak-

age. Clean and polish the shaft sleeve, or replace it

if there are nicks or cuts on either end. If any com-

ponents are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

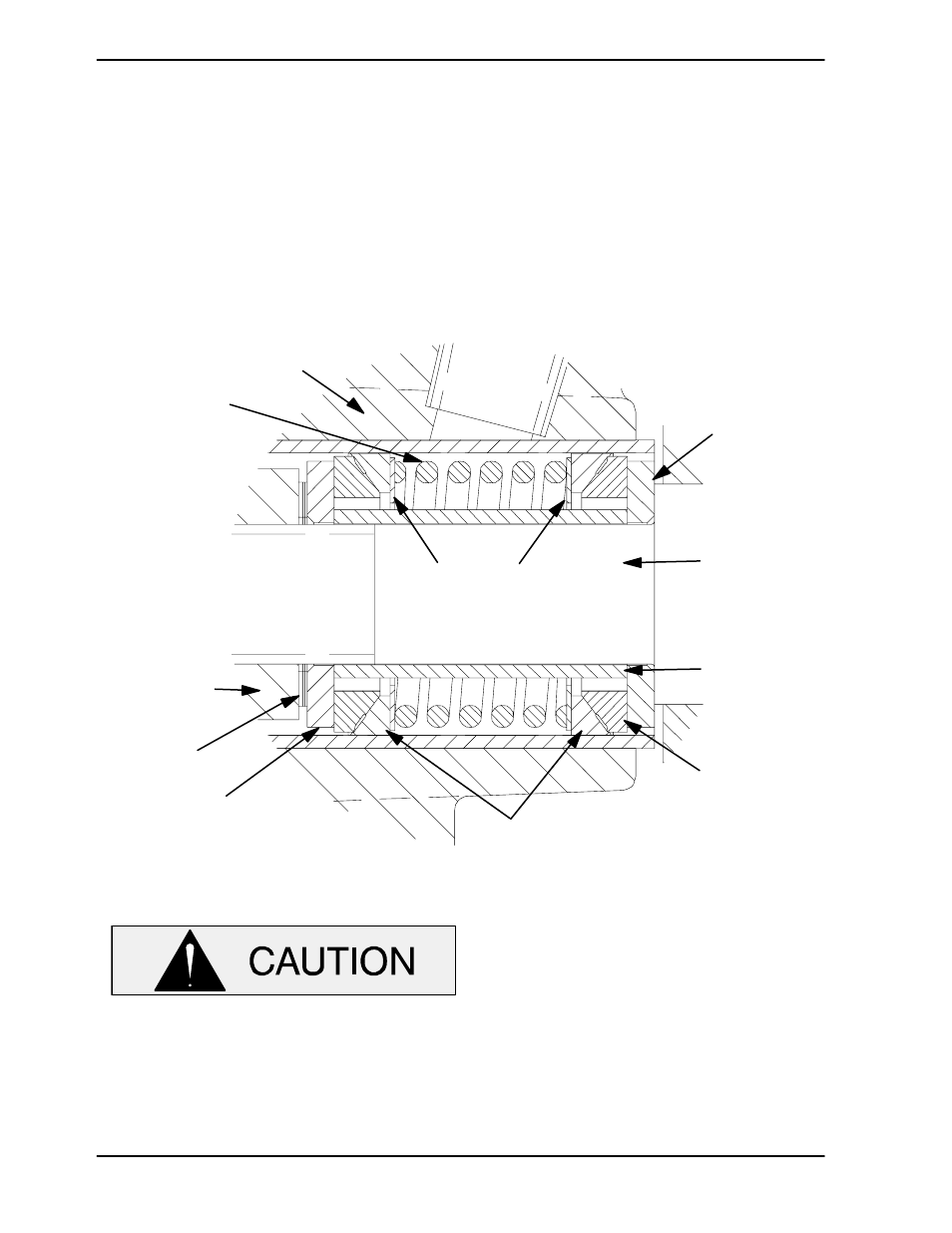

To ease installation of the seal, lubricate the seal

liner (5) with water or a very small amount of oil,

and apply a drop of light lubricating oil on the fin-

ished faces. Assemble the seal as follows, (see Fig-

ure 3).

IMPELLER

SHAFT

STATIONARY

SEAT

STATIONARY

WASHER

ROTATING

ELEMENT

IMPELLER

SHIMS

ROTATING

ELEMENT

SEAL PLATE

SPRING

IMPELLER

SHAFT

SLEEVE

PACKING RINGS

Figure 3. GS625 Seal Assembly

This seal is not designed for operation at

temperatures above 110

_F (43_C). Do not

use at higher operating temperatures.

Before installing the seal, inspect the bore of the

seal liner (5) for wear or grooves which might cause

leakage or damage to the seal packing rings. If the

seal liner requires replacement, remove the seal

plate assembly as described in Seal Removal

And Disassembly, and position it on the bed of an

arbor (or hydraulic) press. Use a new sleeve to

force the old one out. After the new liner is properly

installed, a 1/4-inch (6,4 mm) diameter hole must

be drilled through it to permit the flow of lubricant to

the seal assembly. Be careful to center the drill in

the threaded grease piping hole and not damage

the threads. Deburr the hole from the inside of the

seal liner after drilling.