Gorman-Rupp Pumps 82D2-B 344003 and up User Manual

Page 23

OM−00802

80 SERIES

MAINTENANCE & REPAIR

PAGE E − 5

Do not attempt to lift the complete pump

unit using the lifting eye. It is designed

to facilitate removal or installation of in-

dividual components only. Additional

weight may result in damage to the

pump or failure of the eye bolt.

Remove the gasket set (22) from the pedestal and

seal plate. Tie and tag the gaskets, or measure and

record their thickness for ease of reassembly. Tie

and tag any leveling shims used under the casing

mounting feet to ease reassembly.

Inspect the wear plate assembly (23) and replace it

if badly scored or worn. To remove the wear plate

assembly, remove the capscrew (29) and fiber

washer (30) just below the suction port. Reach

through the suction port and disengage the hard-

ware (24 and 25) from the wear plate. Tap the wear

plate assembly free of the casing.

Impeller Removal

Before removing the impeller, turn the cross arm on

the automatic grease cup (6) clockwise until it rest

against the cover (see Figure 4). This will prevent

the grease from escaping when the impeller is re-

moved.

Immobilize the impeller by wedging a block wood

between the vanes. If removed, install the shaft

key (12). Install a lathe dog on the drive end of the

shaft (13) with the V" notch positioned over the

shaft keyway.

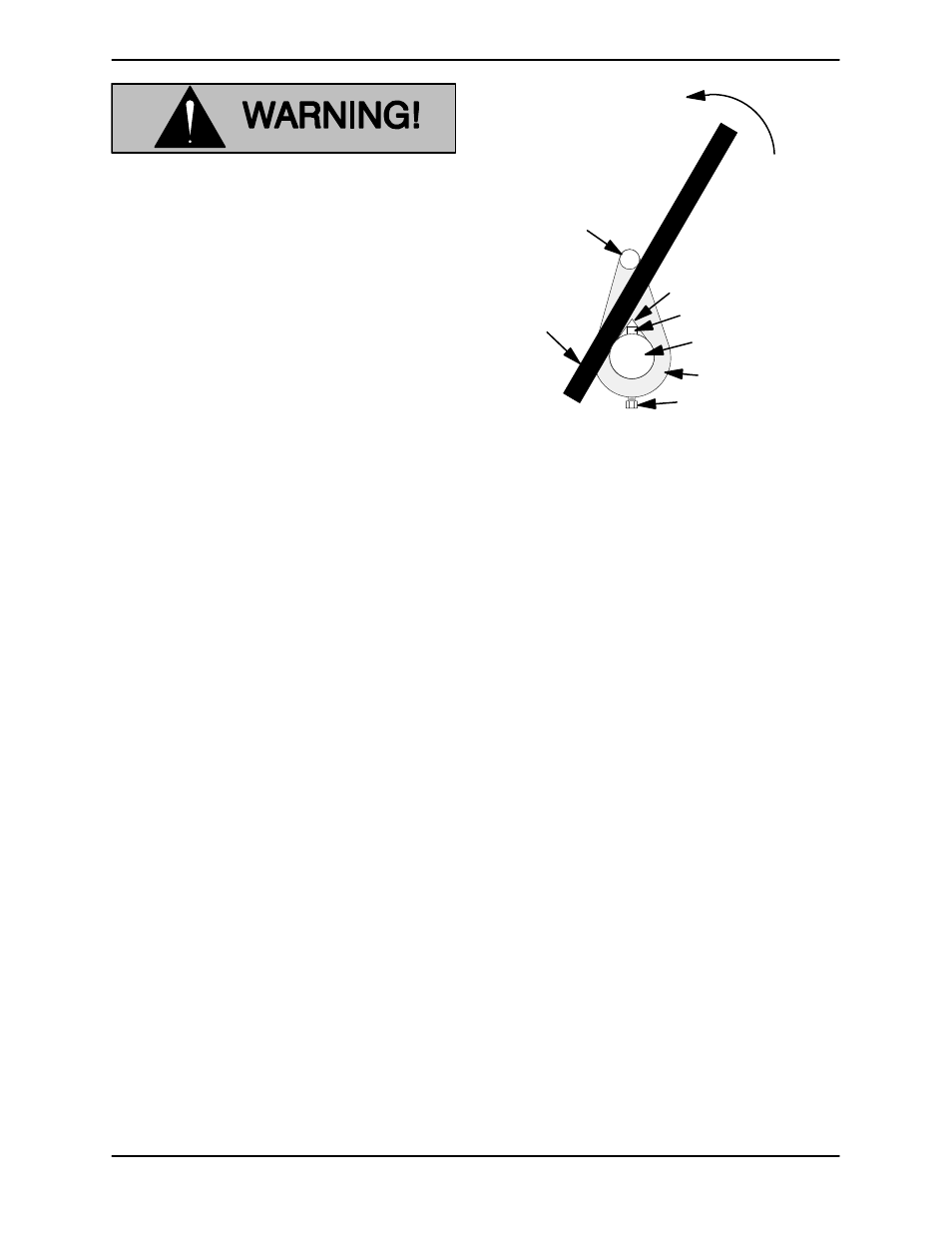

With the impeller rotation still blocked, strike the

lathe dog sharply in a counterclockwise direction

(when facing the drive end of the shaft). The impel-

ler may also be loosened by using a long piece of

heavy bar stock to pry against the arm of the lathe

dog in a counterclockwise direction (when facing

the drive end of the shaft) as shown in Figure 2.

Use caution not to damage the shaft or keyway.

When the impeller breaks loose, remove the lathe

dog and wood block and unscrew the impeller

from the shaft.

Turn

Counterclockwise

Lathe Dog Arm

V" Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 2. Loosening Impeller

Unscrew the impeller from the shaft. Use caution

when removing the impeller; tension on the seal

spring will be released as the impeller is un-

screwed.

Inspect the impeller and replace it if cracked or

badly worn. Slide the impeller adjusting shims (4)

off the impeller shaft. Tie and tag the shims, or

measure and record their thickness for ease of

reassembly.

Seal Removal and Disassembly

(Figures 1 or 3)

Remove the grease cup and piping (6, 7 and 8)

from the seal plate. Slide the seal plate (21) and

seal assembly off the shaft (13) as a unit. Carefully

remove the rotating and stationary seal elements,

packing rings, stationary washers, seal spring and

shaft sleeve from the seal plate.

Inspect the seal liner (5) for wear or grooves which

could cause leakage or damage to the seal pack-

ing rings. The seal liner is a press fit in the seal plate

and does not normally require replacement. If seal

liner replacement is required, refer to Seal Reas-

sembly and Installation.

If no further disassembly is required, see Seal

Reassembly and Installation.