Gorman-Rupp Pumps 112A20-B 814882 and up User Manual

Page 29

OM−00701

10 SERIES

MAINTENANCE & REPAIR

PAGE E − 9

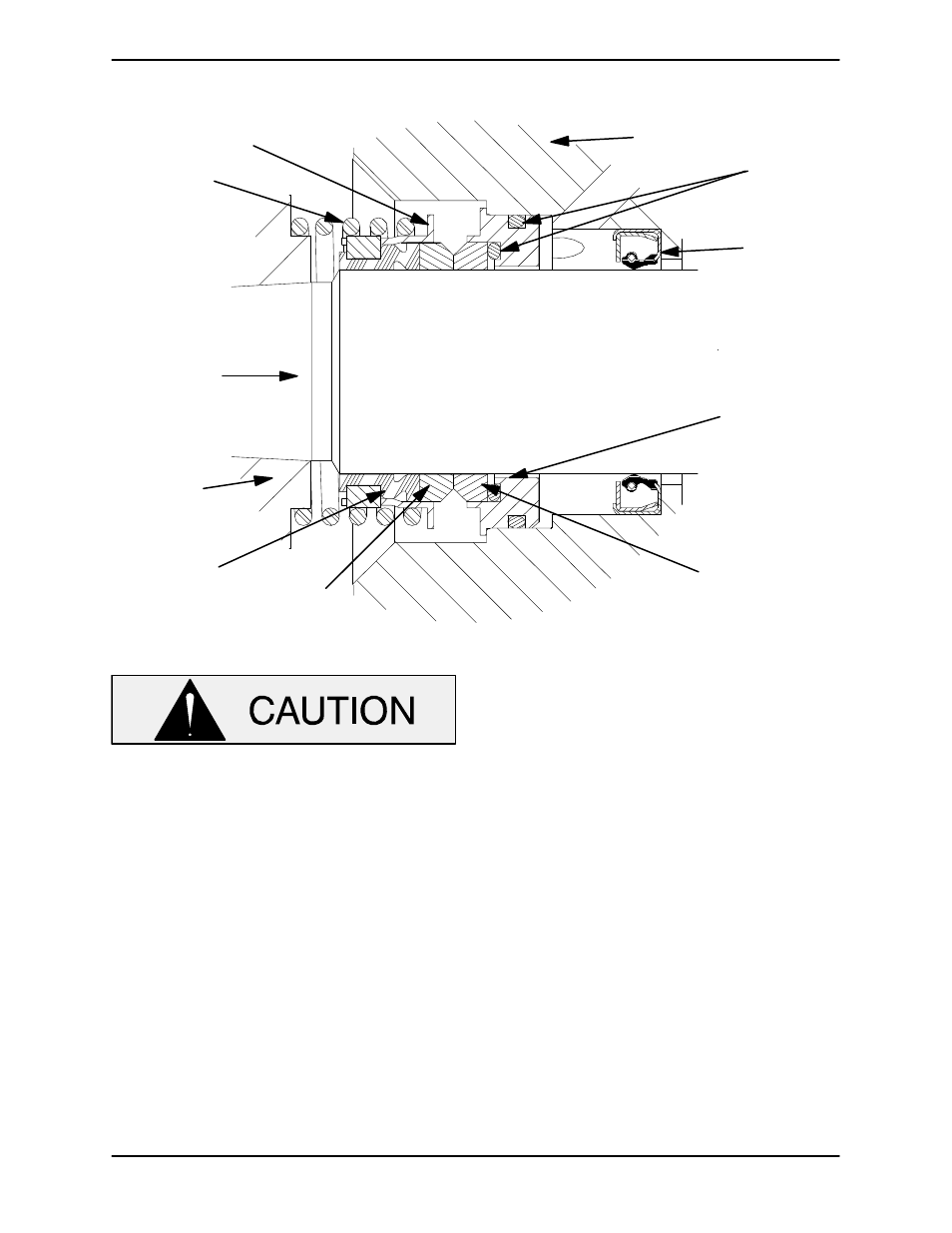

amount of oil, and apply a drop of light lubricating

oil on the finished faces. Assemble the seal as fol-

lows (see Figure E−4).

IMPELLER

SHAFT

IMPELLER

RETAINER

ROTATING

ELEMENT

STATIONARY

ELEMENT

SEAL PLATE

SEAT

STATIONARY

OIL

SEAL

O-RINGS

BELLOWS

SPRING

Figure E−4. 12590B Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lay the seal plate on a flat surface with the impeller

side up. Press the oil seal (31) into the seal plate

with the lip positioned as shown in Figure E−1.

Press the stationary subassembly (consisting of

the stationary seat, O-rings and stationary ele-

ment) into the seal plate until fully seated.

Slide the seal plate onto the shaft and secure it to

the pedestal (28) with the round head machine

screws (12). Use caution not to damage the sta-

tionary portion of the seal on the shaft shoulders.

Slide the rotating subassembly (consisting of the

rotating element, retainer and bellows) onto the lu-

bricated shaft until the seal elements contact. In-

stall the seal spring.

Reinstall the air vent and piping (6, 7 and 8) and

bottle oiler and piping (9, 10 and 11). Lubricate the

seal assembly as indicated in LUBRICATION, af-

ter the impeller is installed.

Impeller Installation

There is a wear ring welded to the impeller to form

the impeller assembly (3). Inspect the impeller and

wear ring for excessive wear, damage or cracks. If

the impeller or wear ring require replacement, the

complete assembly must be replaced; individual

parts are not sold separately.

Install the woodruff key (81) and press the impeller

onto the shaft until fully seated.

Remove the setscrews (63) from the impeller nut

(65). Apply Never-Seez" or equivalent compound

to the shaft threads and screw the impeller nut onto

the shaft. Immobilize the impeller as shown in Fig-