Gorman-Rupp Pumps 112A20-B 814882 and up User Manual

Page 27

OM−00701

10 SERIES

MAINTENANCE & REPAIR

PAGE E − 7

Clean the bearings thoroughly in fresh cleaning

solvent. Dry the bearings with filtered compressed

air and coat with light oil.

Bearings must be kept free of all dirt and

foreign material. Failure to do so will great-

ly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing fail-

ure.

Rotate the bearings by hand to check for rough-

ness or binding and inspect the bearing balls. If ro-

tation is rough or the bearing balls are discolored,

replace the bearings.

The bearing tolerances provide a tight press fit

onto the shaft and a snug slip fit into the pedestal.

Replace the bearings, shaft, or pedestal if the

proper bearing fit is not achieved.

If bearing replacement is required, use a bearing

puller to remove the bearings from the shaft.

Shaft and Bearing Reassembly and Installation

Clean and inspect the bearings as indicated in

Shaft and Bearing Removal and Disassembly.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings

be replaced any time the shaft and bear-

ings are removed.

Inspect the shaft for distortion, nicks or scratches,

or for thread damage on the impeller end. Dress

small nicks and burrs with a fine file or emery cloth.

Replace the shaft if defective.

The bearings may be heated to ease installation.

An induction heater, hot oil bath, electric oven, or

hot plate may be used to heat the bearings. Bear-

ings should never be heated with a direct flame or

directly on a hot plate.

NOTE

If a hot oil bath is used to heat the bearings, both the

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor-

oughly filtered.

Use caution when handling hot bear-

ings to prevent burns.

Heat the bearings to a uniform temperature no

higher than 250

_F (120_C), and slide the bearings

onto the shaft, one at a time, until they are fully

seated. This should be done quickly, in one con-

tinuous motion, to prevent the bearings from cool-

ing and sticking on the shaft.

NOTE

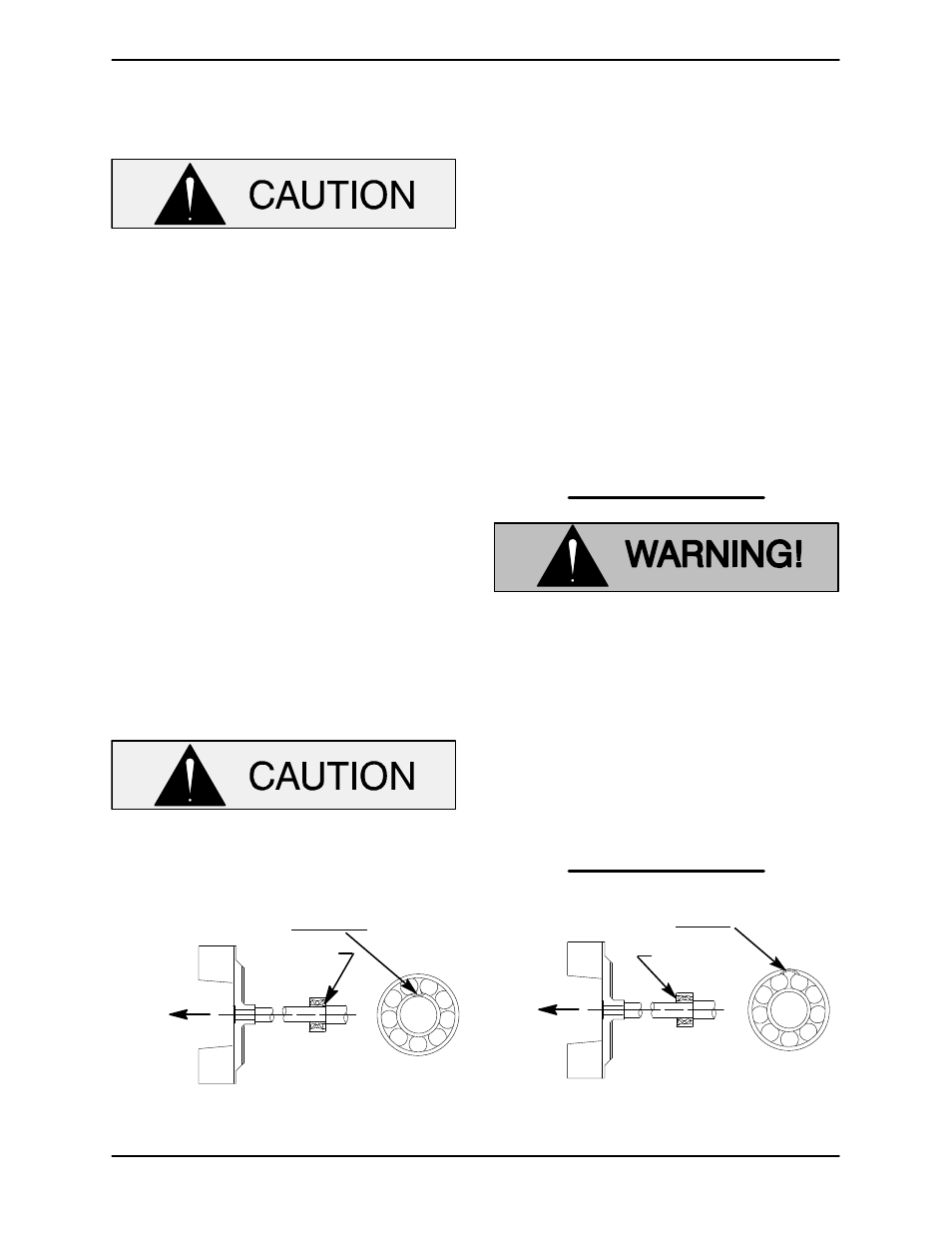

Position the inboard bearing (16) on the shaft as in-

dicated by the following illustrations.

INSTALLATION OF NEW DEPARTURE OR

BCA/FEDERAL MOGAL 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

INSTALLATION OF MRC/SKF 5300M OR

FAFNIR 5300W SERIES BEARINGS

(OPEN OR ENCLOSED IMPELLERS)

LOADING

DIRECTION OF

THRUST

BALL LOADING

GROOVE POSITIONED

AWAY FROM IMPELLER

GROOVE

DIRECTION OF

THRUST

LOADING

BALL LOADING

GROOVE POSITIONED

TOWARD IMPELLER

GROOVE

Figure E−3. Bearing Installation