Gorman-Rupp Pumps 16C2-F4L 1319251 and up User Manual

Page 31

OM-00725

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

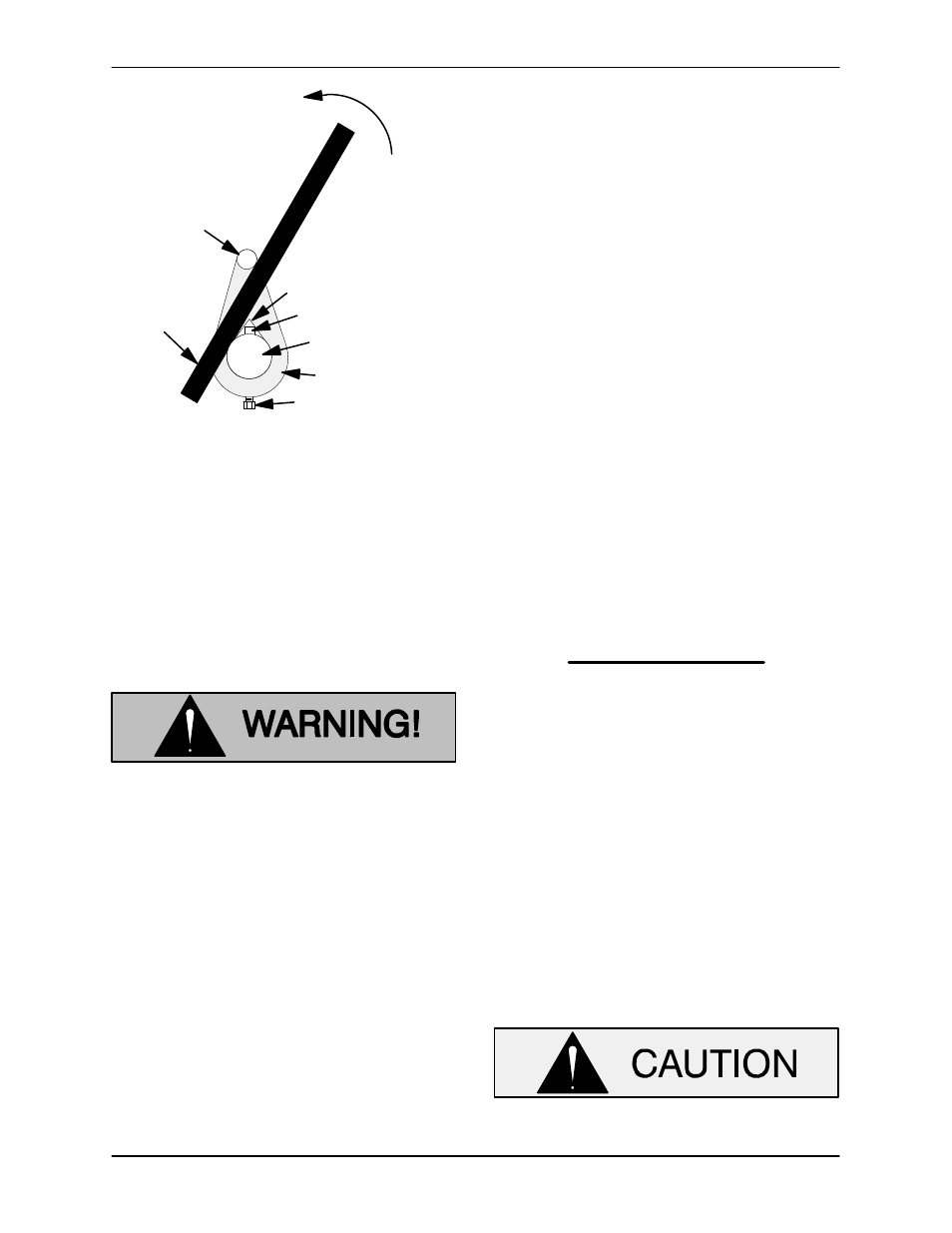

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 4. Loosening Impeller

Pump Casing Removal

(Figure 2)

Remove the nuts (16) securing the pump casing to

the seal plate (48). Use the standard 5/8-11 UNC

lifting eye in the tapped hole in the top of the pump

casing and a hoist and sling of suitable capacity to

separate the casing from the seal plate and inter

mediate.

Do not attempt to lift the complete pump

unit using the lifting eye. It is designed

to facilitate removal or installation of in

dividual components only. Additional

weight may result in damage to the

pump or failure of the eye bolt.

Remove the casing gaskets (49) and any leveling

shims used under the casing mounting feet. Tie

and tag the gaskets and shims for ease of reass

embly.

Impeller Removal

(Figure 2)

With the impeller (2) loosened as previously de

scribed, unscrew it from the shaft. Use caution

when removing the impeller; tension on the shaft

seal spring will be released as the impeller is un

screwed. Inspect the impeller and replace if

cracked or badly worn.

Slide the impeller adjusting shims (31) off the im

peller shaft (42). Tie and tag the shims or measure

and record their thickness for ease of reassembly.

Seal Removal and Disassembly

(Figure 2)

To remove the seal assembly (3), remove the

grease cup and piping (17, 18 and 19). Slide the

seal plate and seal parts off the shaft as a single

unit. Be careful not to drop or damage any seal

parts.

Carefully remove the stationary and rotating seal

elements, packing rings, seal spring, and shaft

sleeve from the seal plate.

NOTE

The seal assembly may be removed without com

pletely disassembling the pump by removing the

impeller through the back cover opening and using

a pair of stiff wires with hooked ends to pull the seal

parts out of the seal plate.

Inspect the seal liner (76) for wear or grooves

which could cause leakage or damage to the seal

packing rings. The seal liner is a press fit in the seal

plate, and does not normally require replacement.

If replacement is necessary, see Seal Installation.

If no further disassembly is required, refer to Seal

Reassembly And Installation.

Shaft and Bearing Removal and Disassembly

(Figure 2)

When the pump is properly operated and main

tained, the intermediate should not require disas

sembly. Disassemble the shaft and bearings only

when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations