Gorman-Rupp Pumps RD2A31-BAR All serial numbers User Manual

Page 9

OM-03989

RS AND RD SERIES PUMPS

PAGE B - 3

INSTALLATION

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid‐wall, rein

forced type to prevent collapse under suction. Us

ing piping couplings in suction lines is not recom

mended.

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make mini

mum use of elbows and fittings, which substan

tially increase friction loss. If elbows are necessary,

use the long‐radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it ex

actly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or cou

plings.

Lines near the pump must be independently sup

ported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose‐type

lines are used, they should have adequate support

to secure them when filled with liquid and under

pressure.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges. If

these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installation closer to the pump may result in erratic

readings.

SUCTION LINES

To avoid air pockets which could affect pump prim

ing, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

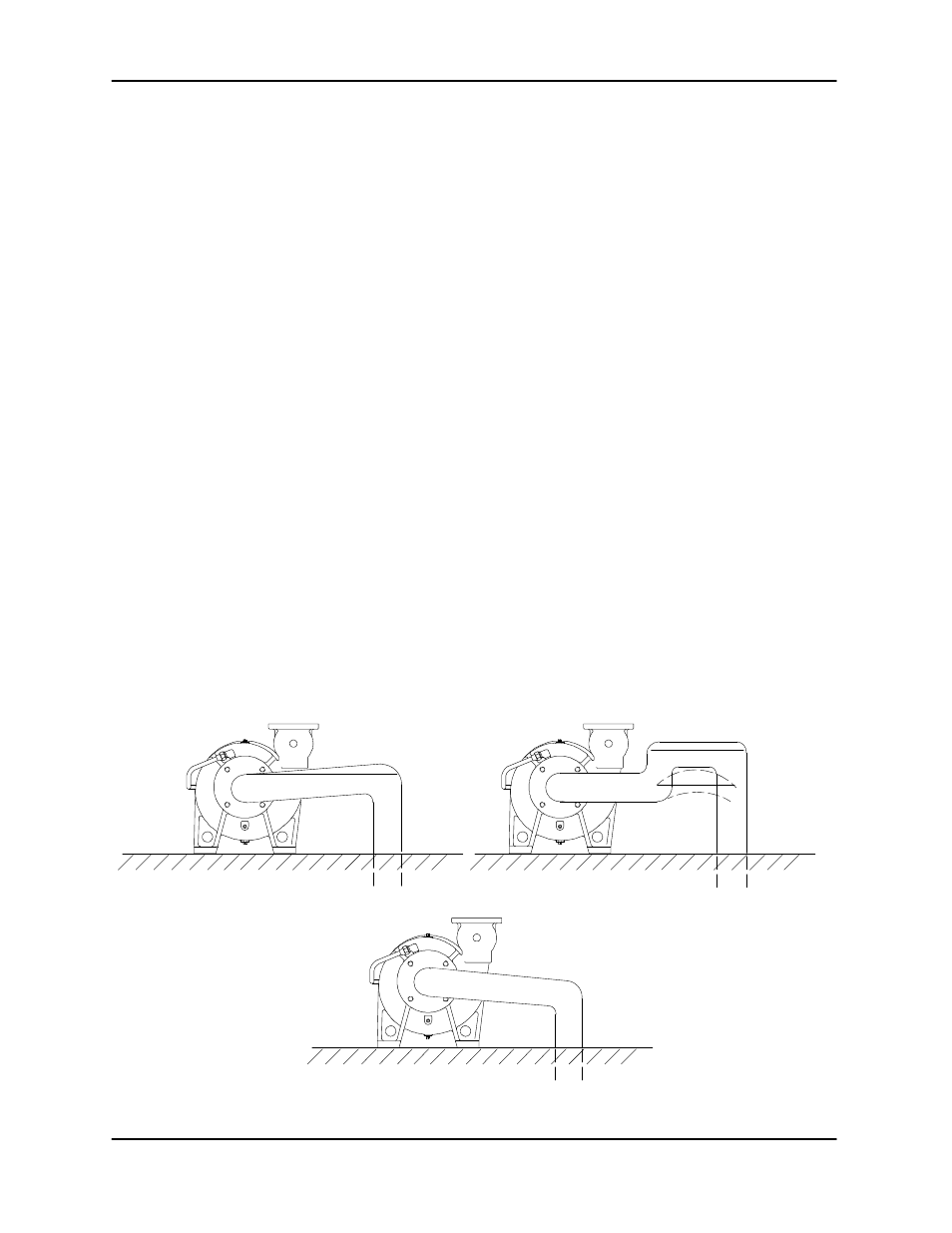

Refer to Figure 1 for the recommended configura

tion of the suction line.

INCORRECT PITCH

VAPOR

POCKETS

INCORRECT LOOPS

RECOMMENDED

NO

POCKETS

PITCH UP TO

SUCTION

WITH NO

LOOPS

VAPOR

POCKETS

Figure 1. Suction Line Configuration

- RD2A31-B All serial numbers RD3A31-B All serial numbers RD3A31-BAR All serial numbers RD3A32-B All serial numbers RD3A32-BAR All serial numbers RD4A31-BAR All serial numbers RD4A31-B All serial numbers RD4A32-B All serial numbers RS2A31-B All serial numbers RD4A32-BAR All serial numbers RS2A31-BAR All serial numbers RS2A32-B All serial numbers RS2A32-BAR All serial numbers RS3A31-BAR All serial numbers RS3A31-B All serial numbers RS3A32-B All serial numbers RS3A32-BAR All serial numbers RS5A31-B All serial numbers RS5A31-BAR All serial numbers RS5A32-B All serial numbers RS5A32-BAR All serial numbers