Gorman-Rupp Pumps RD2A31-BAR All serial numbers User Manual

Page 10

RS AND RD SERIES PUMPS

OM-03989

PAGE B - 4

INSTALLATION

Fittings

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be in

stalled with the flat part of the reducers uppermost

to avoid creating air pockets. Valves are not nor

mally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pock

ets.

Refer to Figure 2 for the recommended entrance

conditions using fittings.

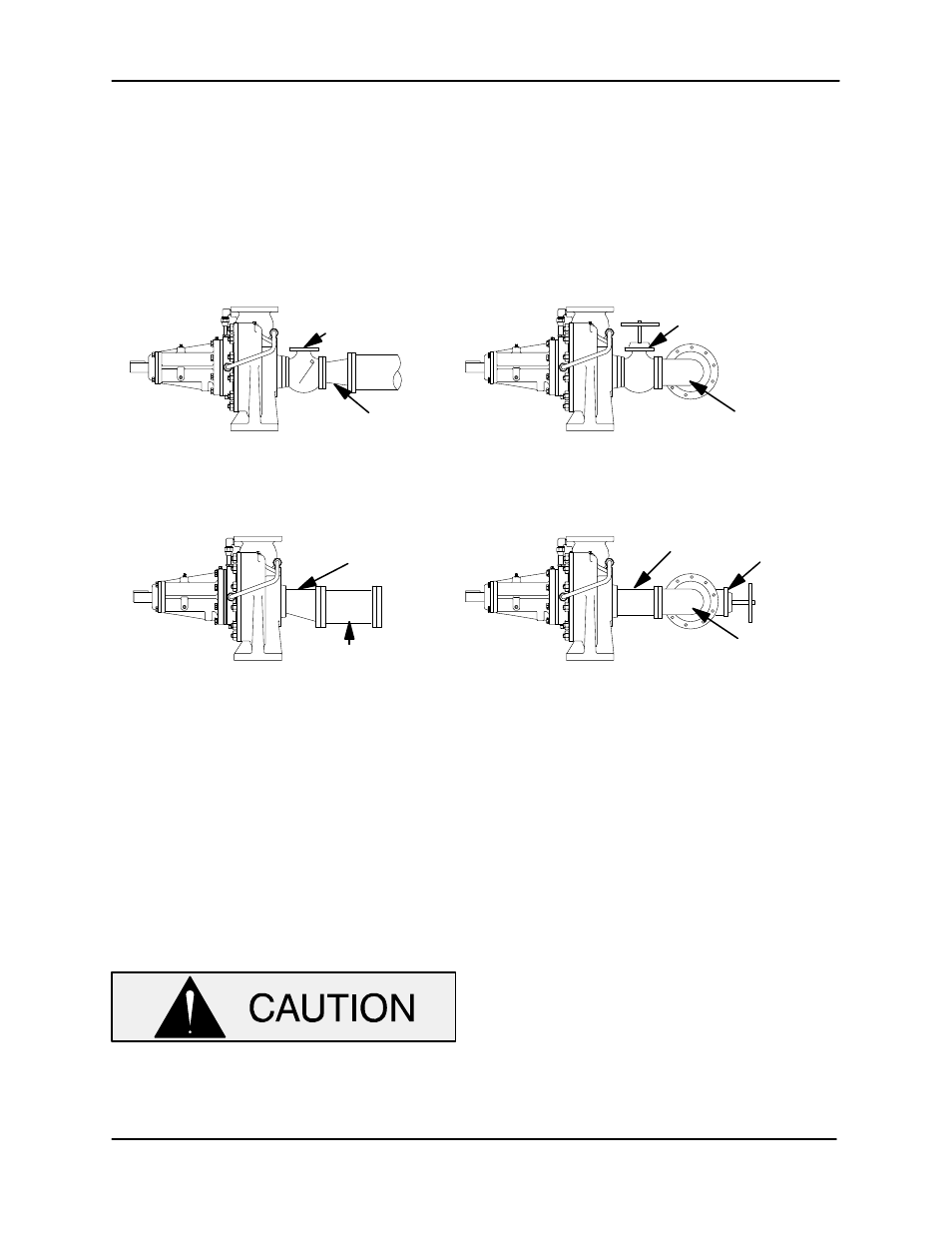

POOR ENTRANCE CONDITIONS

RECOMMENDED ENTRANCE CONDITIONS

CHECK

VALVE

REDUCER

HORIZONTAL

ELBOW

GATE

VALVE

3 TO 4 DIA'S OF

STRAIGHT PIPE

ECCENTRIC

REDUCER

3 TO 4 DIA'S OF

STRAIGHT PIPE

GATE

VALVE

HORIZONTAL

ELBOW

Figure 2. Entrance Conditions Using Fittings

Strainers

A suction strainer was not furnished with this pump

since it is not designed to handle liquids containing

solids. However, to protect the pump from acciden

tal damage a commercially available 80 mesh

screen should be installed in the suction line. Make

certain that the total open area of the screen is at

least three or four times the cross section of the

suction line to ensure an adequate supply of liquid

to the pump.

Damage to the pump resulting from debris

in the suction line will not be covered by the

pump warranty. Before connecting the

suction and discharge piping, carefully

check the storage tank and piping for con

struction debris such as nuts, bolts, wire,

weld slag, and other foreign material. In

stall a commercially available 80 mesh

screen and a filter in the suction line to pre

vent debris from entering the pump.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air

tight seal. Follow the sealant manufacturer's rec

ommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

- RD2A31-B All serial numbers RD3A31-B All serial numbers RD3A31-BAR All serial numbers RD3A32-B All serial numbers RD3A32-BAR All serial numbers RD4A31-BAR All serial numbers RD4A31-B All serial numbers RD4A32-B All serial numbers RS2A31-B All serial numbers RD4A32-BAR All serial numbers RS2A31-BAR All serial numbers RS2A32-B All serial numbers RS2A32-BAR All serial numbers RS3A31-BAR All serial numbers RS3A31-B All serial numbers RS3A32-B All serial numbers RS3A32-BAR All serial numbers RS5A31-B All serial numbers RS5A31-BAR All serial numbers RS5A32-B All serial numbers RS5A32-BAR All serial numbers