Gorman-Rupp Pumps 810A2-F5L 1322933 and up User Manual

Page 30

OM−02396

80 SERIES

MAINTENANCE & REPAIR

PAGE E − 11

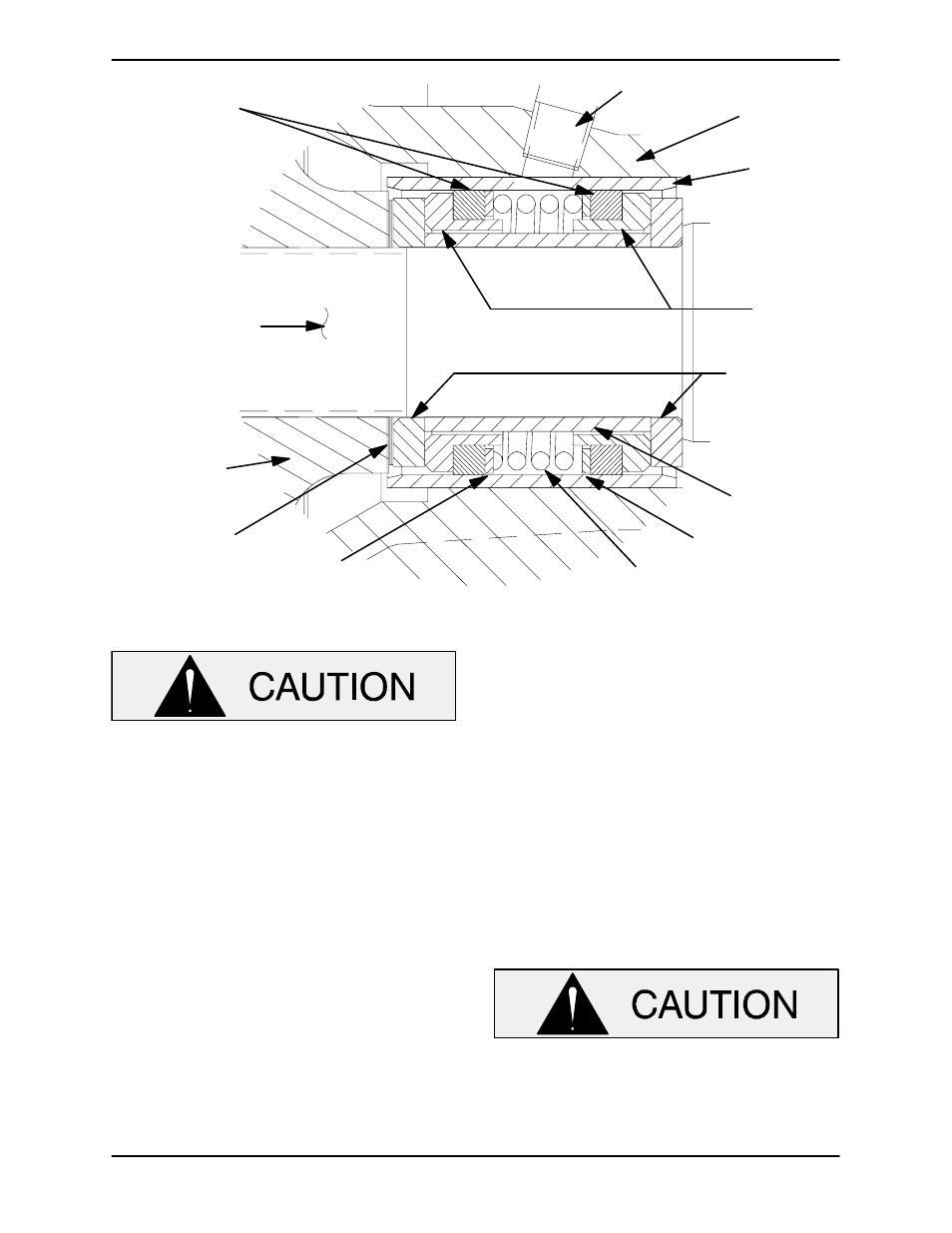

IMPELLER SHAFT

SEAL

LINER

IMPELLER

IMPELLER

SHIMS

GREASE

CUP

PIPING

SPACER

SLEEVE

PACKING

RINGS

WASHER

STATIONARY

ROTATING

ELEMENTS

SPRING

SPRING

SEAL SEATS

SEAL

PLATE

WASHER

SPRING

Figure 4. GS1500 Seal Assembly

This seal is not designed for operation at

temperatures above 110

_ F (43_C). Do

not use at higher operating temperatures.

Slide the inboard rotating element onto the shaft

until the chamfered side seats against the shaft

shoulder.

Subassemble the inboard stationary seat, packing

ring and spring washer. Press this subassembly

into the lubricated seal liner. A push tube cut from a

length of plastic pipe would aid this installation.

The O.D. of the pipe should be approximately the

same diameter as the O.D. of the seal spring.

Install the spacer sleeve and spring.

Subassemble the outboard stationary seat, pack-

ing ring and spring washer. Press this subassem-

bly into the lubricated seal liner.

Install the outboard rotating element with the

chamfered side facing the impeller.

Reinstall the automatic grease cup and piping (15,

16 and 17) in the seal plate. After the impeller has

been installed, lubricate the seal as indicated in

LUBRICATION.

Impeller Installation

(Figure 2)

Inspect the impeller (2), and replace it if cracked or

badly worn. Install the same thickness of impeller

shims (4) as previously removed and screw the im-

peller onto the shaft until tight.

The shaft and impeller threads must be

completely clean before reinstalling the im-

peller. Even the slightest amount of dirt on

the threads can cause the impeller to seize

to the shaft, making future removal difficult