Gorman-Rupp Pumps PA10A60-4045H-ESP 1485220 and up User Manual

Page 44

PA SERIES

OM-06351

MAINTENANCE & REPAIR

PAGE E - 24

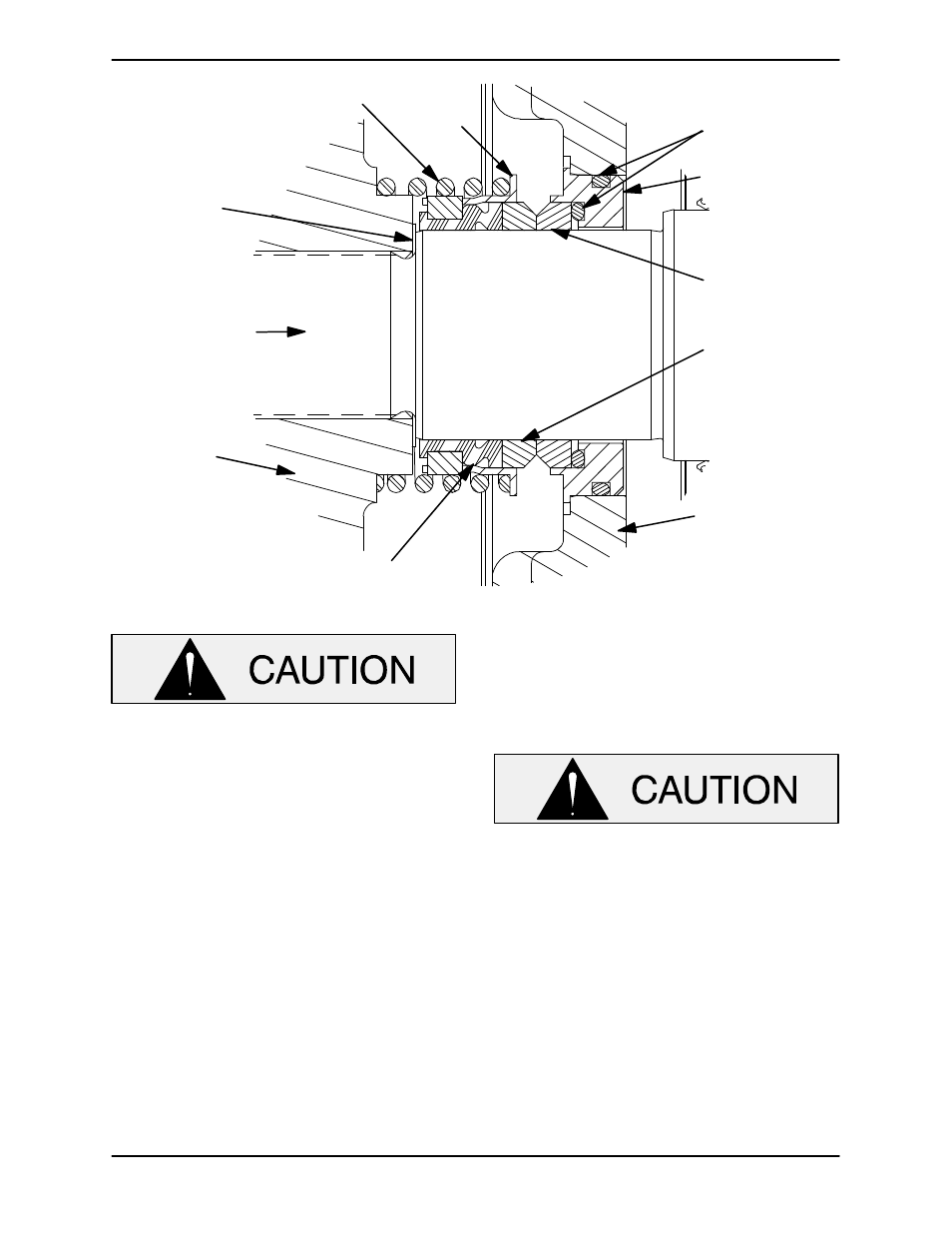

IMPELLER

SHAFT

IMPELLER

SHIMS

O‐RING

IMPELLER

SPRING

RETAINER

STATIONARY

SEAT

BELLOWS

SEAL PLATE

STATIONARY

ELEMENT

ROTATING

ELEMENT

Figure 9. Seal Assembly

This seal is not designed for operation at

temperatures above 160

_F (71_C). Do not

use at higher operating temperatures.

Lubricate the stationary seat O‐ring with water or

light oil. Press the stationary seat and element into

the seal plate (6) until fully seated.

Position the seal plate over the shaft and temporari

ly secure it to the intermediate (14) with four

1/2-UNC x 2‐inch long capscrews and hex nuts

(not supplied). Be careful not to damage the sta

tionary portion of the seal on the shaft threads.

Lubricate the shaft with a small amount of light oil

and slide the rotating subassembly (consisting of

rotating element, bellows and retainer), onto the

shaft until the seal faces touch.

Install the seal spring. Lubricate the seal as indi

cated in LUBRICATION after the impeller is in

stalled.

Impeller Installation And Adjustment

(Figure 6)

Inspect the impeller (2) and replace it if cracked or

badly worn.

The shaft and impeller threads must be

completely clean before reinstalling the im

peller. Even the slightest amount of dirt on

the threads can cause the impeller to seize

to the shaft, making future removal difficult

or impossible without damage to the im

peller or shaft.

Install the same thickness of impeller adjusting

shims (4) as previously removed and screw the im

peller assembly onto the shaft until tight, making

sure the seal spring seats squarely over the shoul

der on the back of the impeller.

NOTE

At the slightest sign of binding, immediately back