Gorman-Rupp Pumps PA10A60-4045H-ESP 1485220 and up User Manual

Page 40

PA SERIES

OM-06351

MAINTENANCE & REPAIR

PAGE E - 20

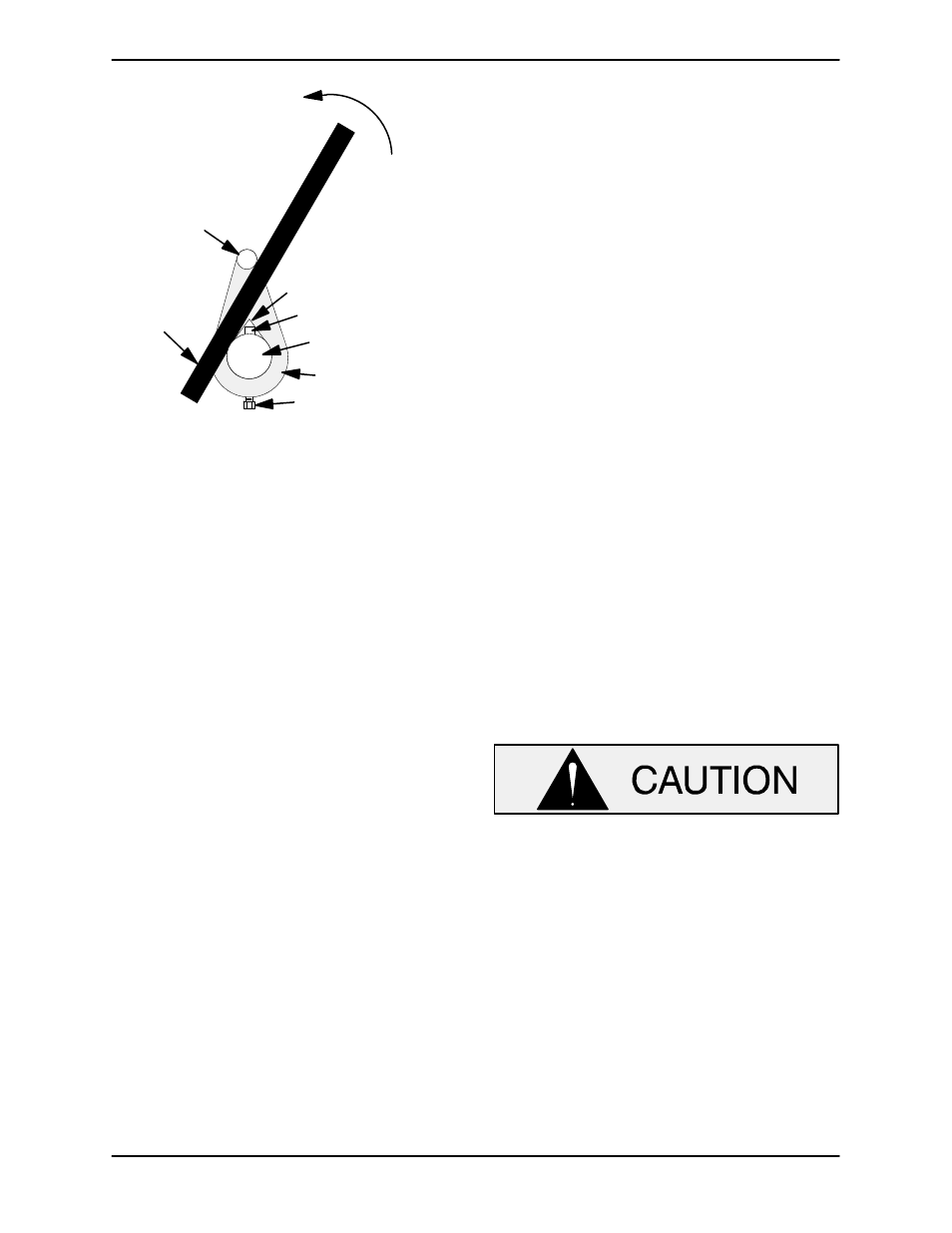

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 8. Loosening Impeller

Pump Casing Removal

(Figure 6)

With the pump end resting on a flat surface and the

drive end facing up, secure a suitable lifting device

to the bellhousing mounting holes in the intermedi

ate (14).

Remove the hardware (9 and 10). Apply tension on

the lifting device and use a pair of pry bars or large

screwdrivers to separate the pump casing at the

gasket (29).

Remove the rotating portion of the pump and place

it on a clean work surface. Discard the pump cas

ing gasket.

Impeller Removal

(Figure 6)

To remove the impeller (2), unscrew it in a counter

clockwise direction (when facing the impeller). Use

caution when removing the impeller; tension on

the shaft seal spring will be released as the impeller

is unscrewed. Inspect the impeller and replace it if

cracked or badly worn.

Seal Removal

(Figures 6 and 9)

Slide the impeller adjusting shims (4) off the impel

ler shaft. Tie and tag the shims or measure and re

cord their thickness for ease of reassembly.

Remove the seal spring. Lubricate the shaft in the

area adjacent to the seal with light oil and work it up

under the bellows. Slide the rotating portion of the

seal (consisting of the bellows, retainer, and rotat

ing element) off the shaft as a unit.

Slide the seal plate and stationary portion of the

seal off the shaft. Position the seal plate on a flat

surface with the impeller side down. Use a wooden

dowel or other suitable tool to press on the back

side of the stationary seat until the seat, element

and O‐rings can be removed.

Remove the seal plate O‐ring (7).

If no further disassembly is required, refer to Seal

Installation.

Shaft and Bearing Removal and Disassembly

(Figure 6)

When the pump is properly operated and main

tained, the bearing housing should not require dis

assembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

Remove the bearing housing drain plug (27) and

drain the lubricant. Clean and reinstall the drain

plug.

Disengage the hardware (15 and 16) and remove

the bearing cover (17), gasket (24) and oil seal

(22). Use a suitably sized dowel to press the oil seal

from the bearing cover.

Place a block of wood against the impeller end of

the shaft (20) and tap the shaft and assembled

bearings (18 and 28) from the intermediate. Press