Gorman-Rupp Pumps PA12A60-B-6068H-ESP 1501367 and up User Manual

Page 49

OM-06261

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 29

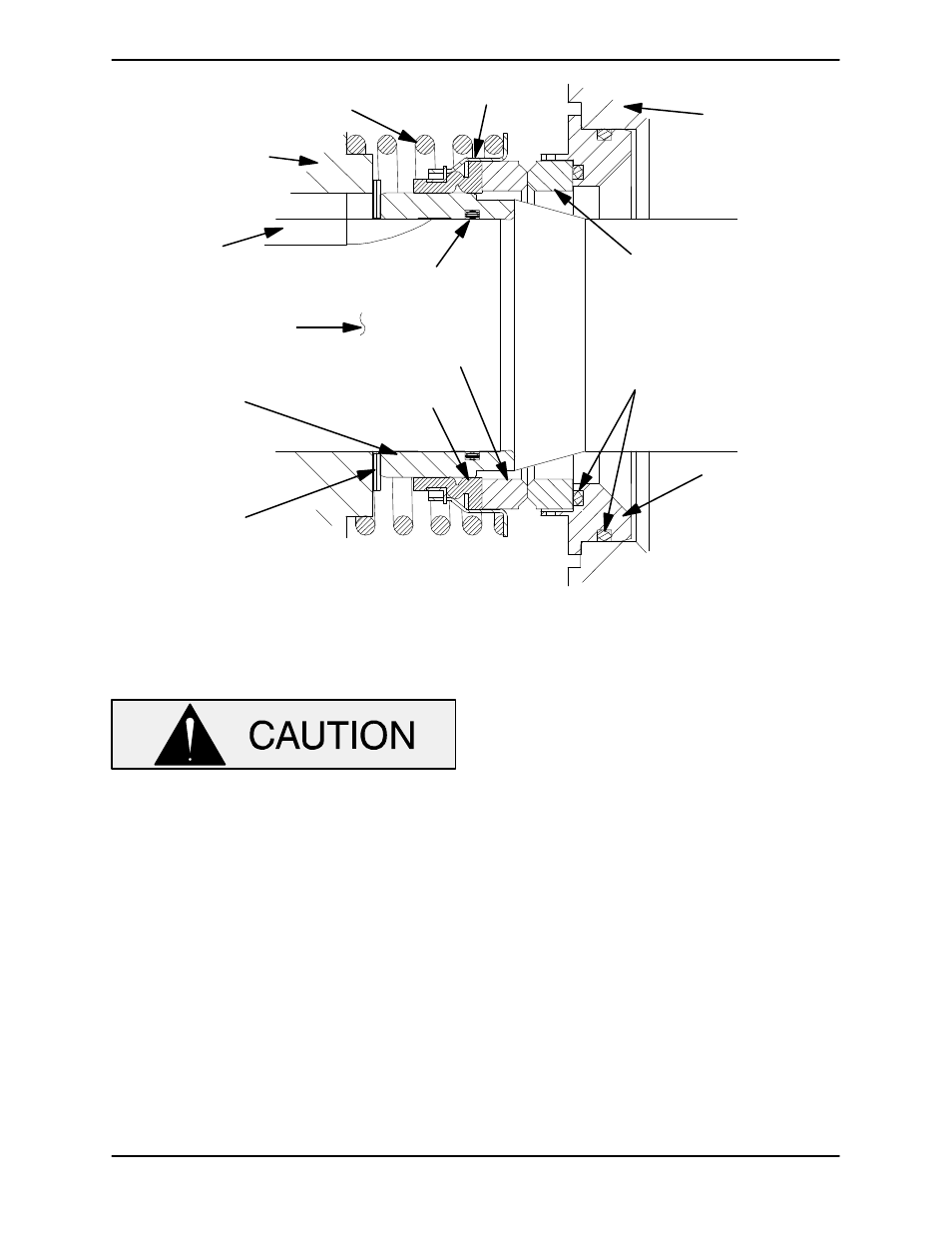

IMPELLER

SHAFT

SPRING

SEAL PLATE

RETAINER

O‐RINGS

BELLOWS

ROTATING

ELEMENT

STATIONARY

SEAT

SLEEVE

O‐RING

IMPELLER

STATIONARY

ELEMENT

SHAFT

SLEEVE

SHAFT

KEY

IMPELLER

SHIMS

Figure 13. Seal Assembly

The standard seal is not designed for oper

ation at temperatures above 160

_F (71_C).

Do not use at higher operating tempera

tures.

Lubricate the outboard stationary seat O‐ring with

water or light oil. Position the seal plate with the im

peller side up and press the stationary subas

sembly (consisting of the stationary seat, O‐rings

and stationary element) into the front of the seal

plate until it seats squarely against the bore shoul

der.

Slide the seal plate and stationary portion of the

seal over the shaft until it is seated against the ped

estal (20). Be careful not to damage the stationary

element or roll or cut the lip of the oil seal (23) on the

shaft keyway. Temporarily secure the seal plate to

the pedestal with three 1/2‐inch by 2‐inch long

capscrews and nuts (not supplied).

Lubricate the seal sleeve O‐ring with a small

amount of light oil and install it in the groove in the

I.D. of the sleeve.

Lubricate the seal sleeve with a small amount of

light oil and slide the rotating subassembly (con

sisting of rotating element, bellows and retainer),

onto the sleeve until the rotating element is just

flush with the turned end of the sleeve.

Slide the sleeve and subassembled seal onto the

shaft until the seal faces contact and the sleeve

seats against the shaft shoulder.

Install the seal spring. Lubricate the seal as indi

cated in LUBRICATION after the impeller, remain

ing pump components, bottle oiler and piping are

installed.