Gorman-Rupp Pumps PA12A60-B-6068H-ESP 1501367 and up User Manual

Page 47

OM-06261

PA SERIES

MAINTENANCE & REPAIR

PAGE E - 27

sleeve and a press to reposition the bearings

against the shaft shoulder.

Secure the assembled shaft and bearings by

clamping on the surface between the bearings.

Use caution not to scratch or mar the part number

etched into the shaft in this area. Install the tab

washer (28) and bearing lock nut (27). Torque the

lock nut to 150 ft. lbs. (1800 in. lbs. or 20,7 m. kg.).

Locate the tab on the lockwasher that aligns with a

slot in the lock nut, and bend the tab over into the

slot.

Slide the shaft and assembled bearings into the

pedestal from the drive end until the retaining in

board bearing (30) seats against the pedestal

bore.

When installing the shaft and bearings into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Press the oil seal (23) into the bearing cap (24) with

the lip positioned as shown in Figure 7. Lubricate

and install a new bearing cap O‐ring (25) and se

cure the bearing cap with the capscrews (22). Use

caution not to cut or roll the lip of the oil seal when

installing the bearing cap.

Press the oil seal (23) into the bearing cap (35) with

the lip positioned as shown in Figure 6. Replace

the bearing cap gasket (29) and secure the bear

ing cap with the capscrews (22). Use caution not to

cut or roll the lip of the oil seal when installing the

bearing cap.

Lubricate the pedestal as indicated in LUBRICA

TION.

Install the sprocket and hub onto the impeller shaft

as follows.

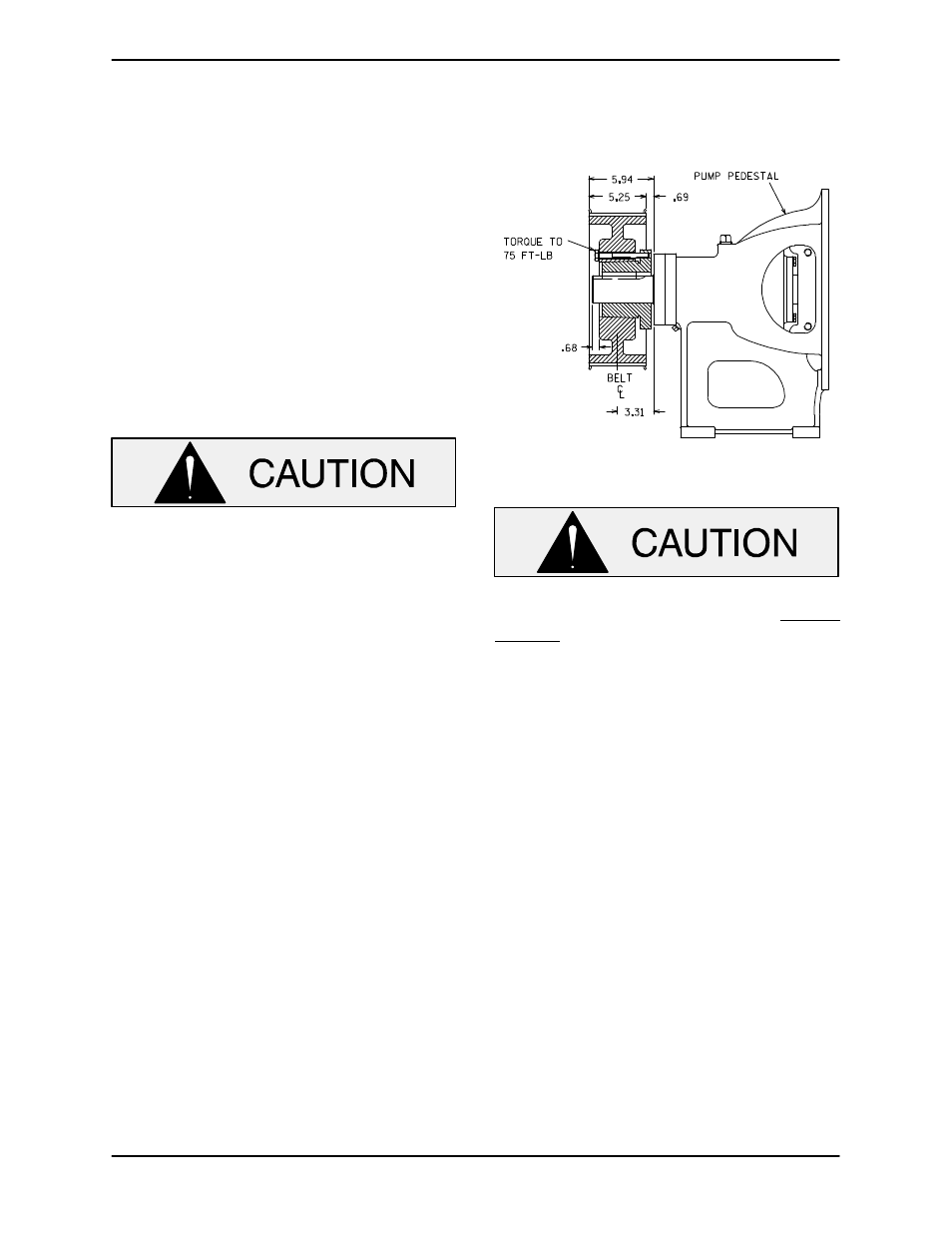

(Figures 7 and 12)

Install the key (31) in the shaft keyway. Align the

keyway in the hub with the shaft key, and slide the

hub onto the shaft with the shoulder positioned to

ward the pedestal.

Slide the sprocket over the hub, align the mounting

screw holes and install the mounting screws.

Position the hub and sprocket to the dimensions

shown in Figure 12 and torque the mounting caps

crews to 75 ft. lbs. (900 in. lbs. or 10.4 m. kg.)

Figure 12. Hub and Sprocket Installation

Make certain that the hub and sprocket are

mounted as shown in Figure 12. This is

critical. If the sprocket is not properly posi

tioned on the shaft, the pump drive belt will

not be properly aligned, which can cause

premature belt or bearing failure.

Pedestal Assembly Installation

(Figure 2)

See Figure 1 and use a suitable hoist and sling to

position the pedestal assembly on the pump sup

port assembly (55). Secure the pedestal to the

pump support assembly using the previously re

moved hardware (14, 17 and 18).

Install the pump drive belt (25, Figure 3) after as

sembling the remaining pump components.

To adjust the drive belt tension, find the center of

the belt span between the pump and engine

sprockets. Use a belt deflection gauge to measure

deflection across the width of the belt at this

point. Use the hardware (13 and 14) to adjust belt

tension to 3/8 inch (9,5 mm) of deflection at 30 lbs.

(13,6 kg.) of pressure. Do not over‐tighten the

drive belt.