Gorman-Rupp Pumps PA6A60-4045D 1110032 thru 1115250 User Manual

Page 13

PA SERIES PUMPS

OM−04402

PAGE B − 7

INSTALLATION

OPERATING

RANGE

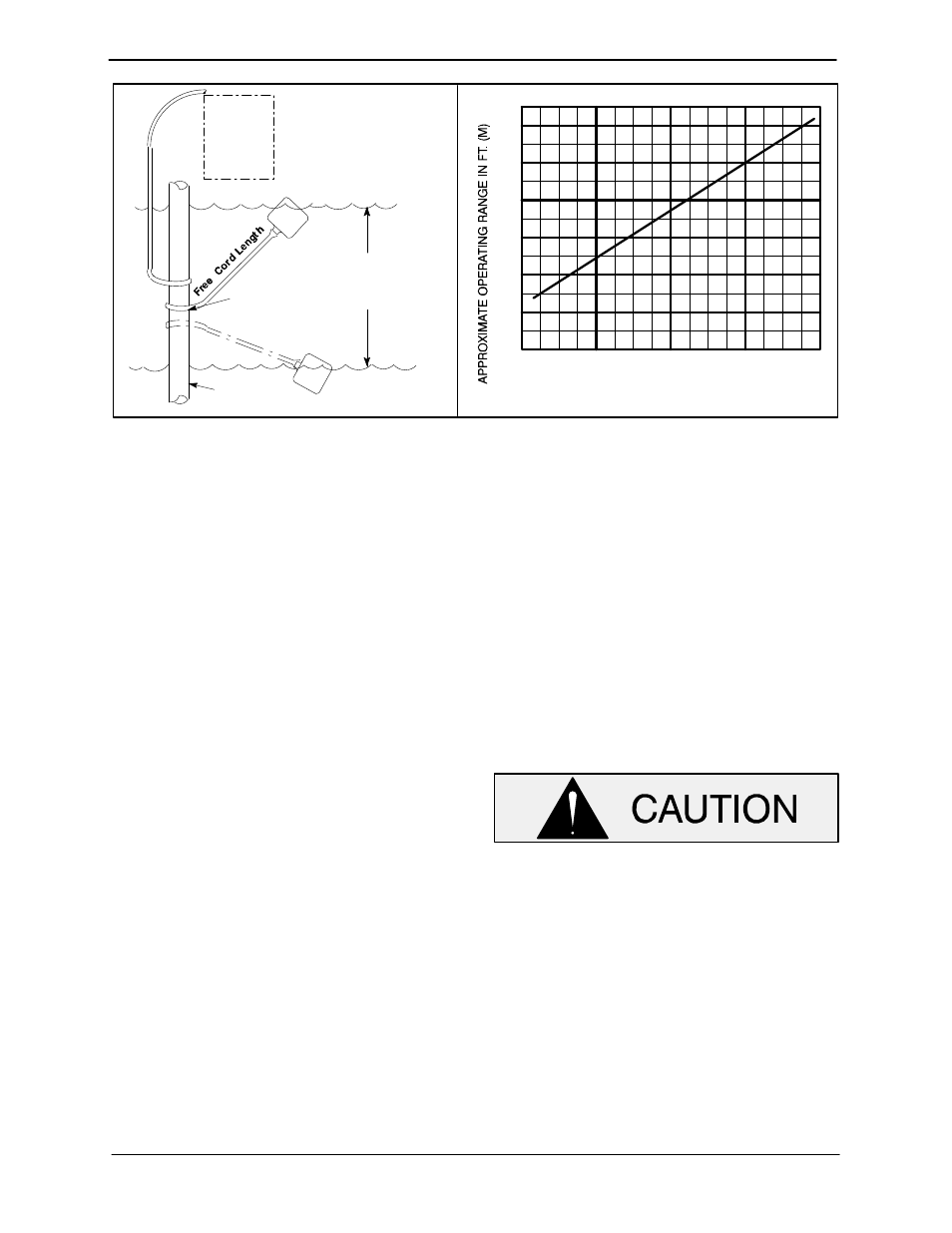

(See Table Below)

CABLE

TETHER

POINT

OFF

(Emptying)

ON

(Filling)

ON

(Emptying)

OFF

(Filling)

1.25" Pipe

(Not Furnished)

ENGINE

CONTROL

BOX

1.0

(0.3)

APPROXIMATE FREE CORD LENGTH IN FT. (M)

0.5

(.15)

1.0

(0.3)

1.5

(.46)

2.0

(0.6)

2.5

(.76)

3.0

(0.9)

2.0

(0.6)

3.0

(0.9)

4.0

(1.2)

Figure B−5. Float Switch Data

Submersible Transducer Installation

The Electronic Pressure Switch (EPS) autostart

system employs a submersible transducer level

sensor with 75 feet (22,9 m) of signal cable con-

nected to the EPS.

The transducer sensor converts pressure to an

electrical signal proportional to liquid level. This

electrical signal is distributed to the digital display

on the EPS through a scaling circuit which con-

verts the electrical signal to feet of water".

When installing the transducer sensor, note the fol-

lowing:

a. Handle the signal cable and transducer sen-

sor with care during installation. Carefully

lower the sensor into the wet well or sump; do

not drop it to the bottom. To avoid clogging,

suspend the sensor off the bottom.

b. Be sure to provide sufficient room in the wet

well or sump so that the sensor does not get

drawn into the suction line. To prevent this, a

flexible suction hose may be extended to lay

along the bottom of the wet well or sump. The

sensor can then be attached to the hose

above the point where it bends along the bot-

tom. See Figure B−6 for a typical installation.

c. Allow slack in the signal cable so that the sen-

sor weight does not pull on the connection.

d. The wet well or sump must be vented to atmo-

sphere.

e. The EPS is scaled in feet of water column. If

the measured medium is other than 1.0 spe-

cific gravity, the reading on the EPS should be

divided by the specific gravity of the mea-

sured medium to obtain the actual level.

f. Thoroughly clean the sensor after each use

to prevent clogging.

Do not disassemble the transducer sensor

or loosen the compression nut at the signal

cable entry. This will void warranty. There

are no user-serviceable parts inside. Do

not nick or cut the jacket of the signal

cable; this will cause leakage and void

warranty. Connect the signal cable only to

the EPS terminals for this purpose and to

no other power source.