Installation - section b – Gorman-Rupp Pumps UNIT 608 1395614 and up User Manual

Page 8

UNIT SERIES

OM-01228

PAGE B - 1

INSTALLATION

INSTALLATION - SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar

range the pump and piping.

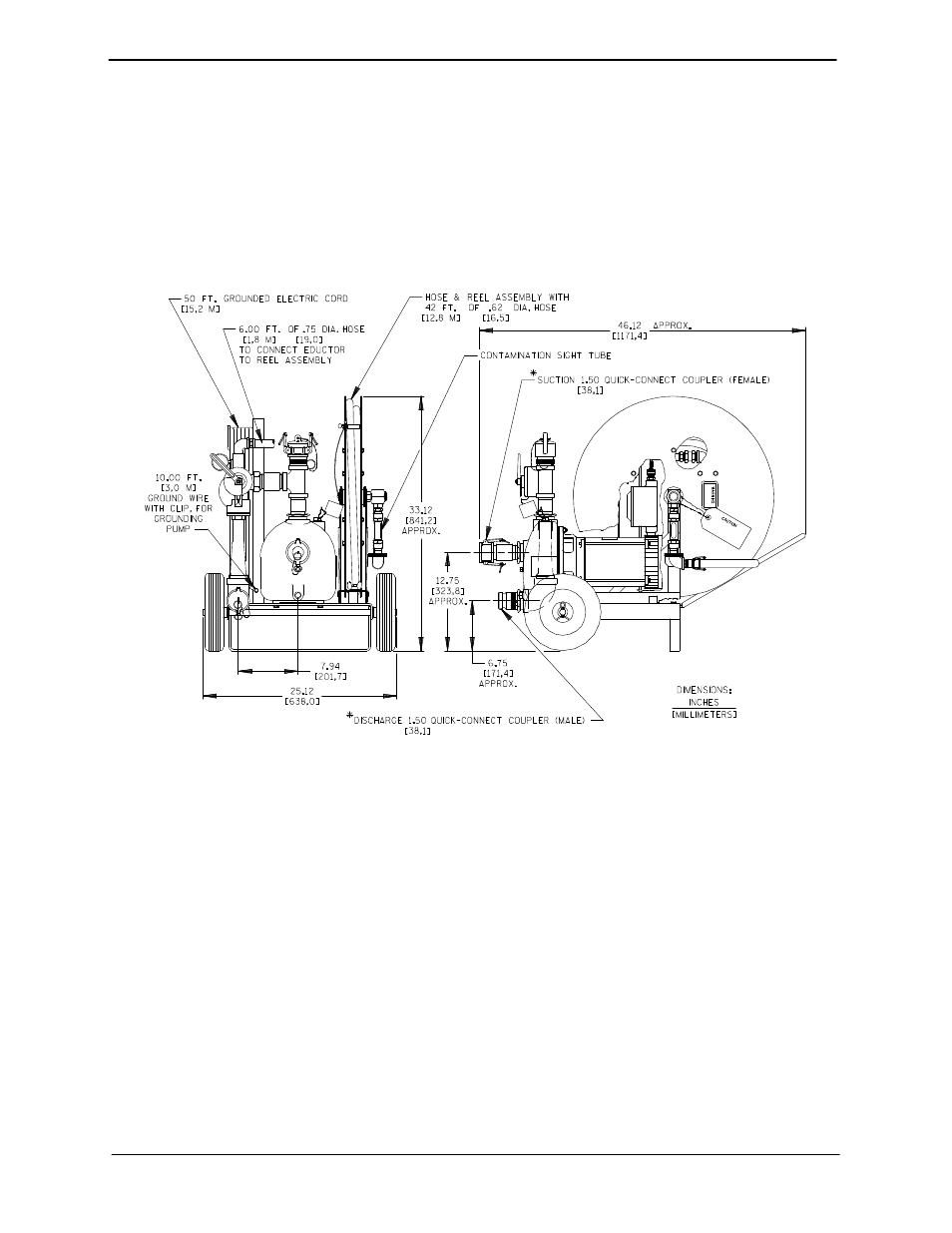

Pump Dimensions

See Figure 1 for the approximate physical dimen

sions of this pump.

OUTLINE DRAWING

Figure 1. Pump Model UNIT 608

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be

fore shipment from the factory. Before installation,

inspect the unit for damage which may have oc

curred during shipment. Check as follows:

a. Inspect the pump, reel assembly, hose and

motor for cracks, dents, damaged threads,

and other obvious damage.

b. Check for and tighten loose attaching hard

ware. Since gaskets tend to shrink after dry

ing, check for loose hardware at mating sur

faces.

c. Carefully read all tags, decals, and markings

on the unit, and perform all duties indicated.

d. If the pump and motor have been stored for

more than 12 months, some of the compo

nents or lubricants may have exceeded their

maximum shelf life. These must be inspected

or replaced to ensure maximum pump serv

ice.

e. Check to ensure the following standard

equipment items are included with the pump

assembly:

S Detachable reel assembly.

S 42 foot long hydrocarbon‐resistant hose.

S 8 foot long connector hose.

S 15 foot long suction and discharge hose.

S 12 foot long stainless steel standpipe.

S 10 foot long ground wire.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your