Gorman-Rupp Pumps UNIT 608 1395614 and up User Manual

Page 19

OM-01228

UNIT SERIES

TROUBLESHOOTING

PAGE D - 2

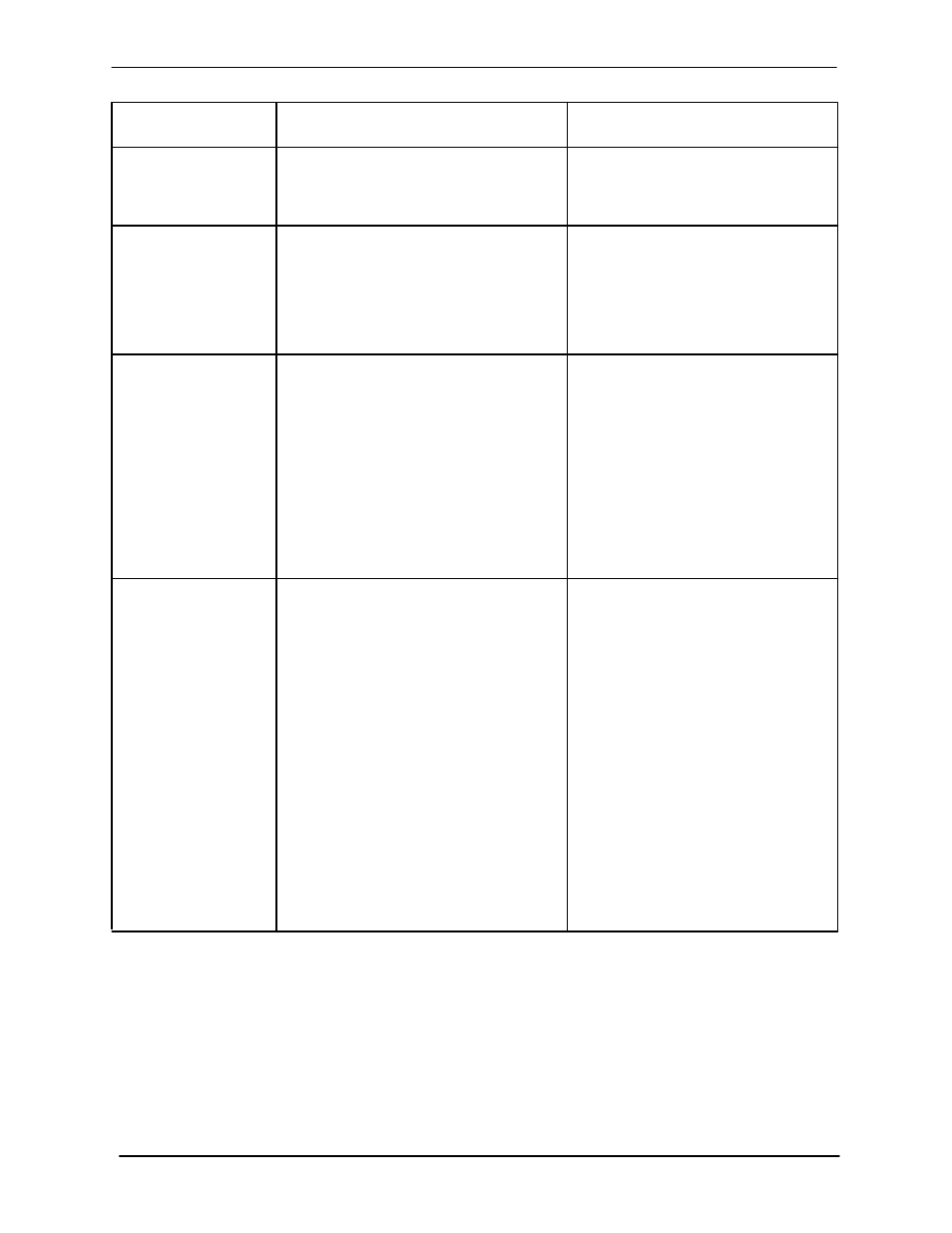

TROUBLE

POSSIBLE CAUSE

PROBABLE REMEDY

PUMP REQUIRES

TOO MUCH

POWER

UNIT CLOGS

FREQUENTLY

EXCESSIVE NOISE

Liquid solution too thick.

Dilute if possible.

Low or incorrect voltage.

Measure voltage, both when pump

is running and when shut off.

Liquid solution too thick.

Dilute if possible.

Discharge line clogged or restricted;

Check discharge lines; straighten

hose kinked.

hose.

Feeding hose assembly into tank too

Feed hose assembly slowly and

fast.

watch flow through sight glass.

Cavitation in pump.

Reduce suction lift and/or friction

losses in suction line. Record

vacuum and pressure gauge

readings and consult local

representative or factory.

Pumping entrained air.

Locate and eliminate source of air

bubble.

Pump or drive not securely mounted.

Secure mounting hardware.

Impeller clogged or damaged.

Clean out debris; replace damaged

parts.

Hose assembly has become tangled

Shutoff unit and drain hose

and the flat spring strap inside the hose assembly back into the tank. Re‐

will not allow the assembly to easily

move reel from the standpipe.

slide back through the bottom opening

Do not force the hose assembly

of the standpipe. Tangling has occurred through the standpipe. Carefully

due to improperly directing the hose

raise the standpipe (with the hose

inside the tank or by continuing to feed

assembly still inside) out of the tank

the hose assembly after the nozzle has

fill pipe, then carefully feed the

contacted the end of the tank.

hose assembly back through the

standpipe. Roll the hose assembly

back into the reel, making sure the

steel strip inside the hose is not

twisted. The steel strip must roll

parallel to the axis of the reel

(similar to the tape in a measuring

tape ruler). Set up the equipment

again, this time being careful to

properly feed the hose assembly

into the tank.

HOSE ASSEMBLY

WILL NOT REEL

BACK UP THE

STANDPIPE. HOSE

SEEMS STUCK IN

STANDPIPE.