Gorman-Rupp Pumps UNIT 608-A 1395614 and up User Manual

Page 9

OM-01238

UNIT SERIES

PAGE B - 2

INSTALLATION

Gorman‐Rupp distributor or the factory to deter

mine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

UNIT INSTALLATION

Lifting

This unit is mounted on a two‐wheel moveable

base. It weighs approximately 260 pounds (118 ki

lograms) including suction and discharge hoses

and the standpipe. If it is necessary to lift the unit,

use lifting equipment with a capacity of 5 times the

weight of the unit to ensure safe lifting.

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or dam

age to equipment.

Mounting

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mount

ing is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibra

tion.

Specifications

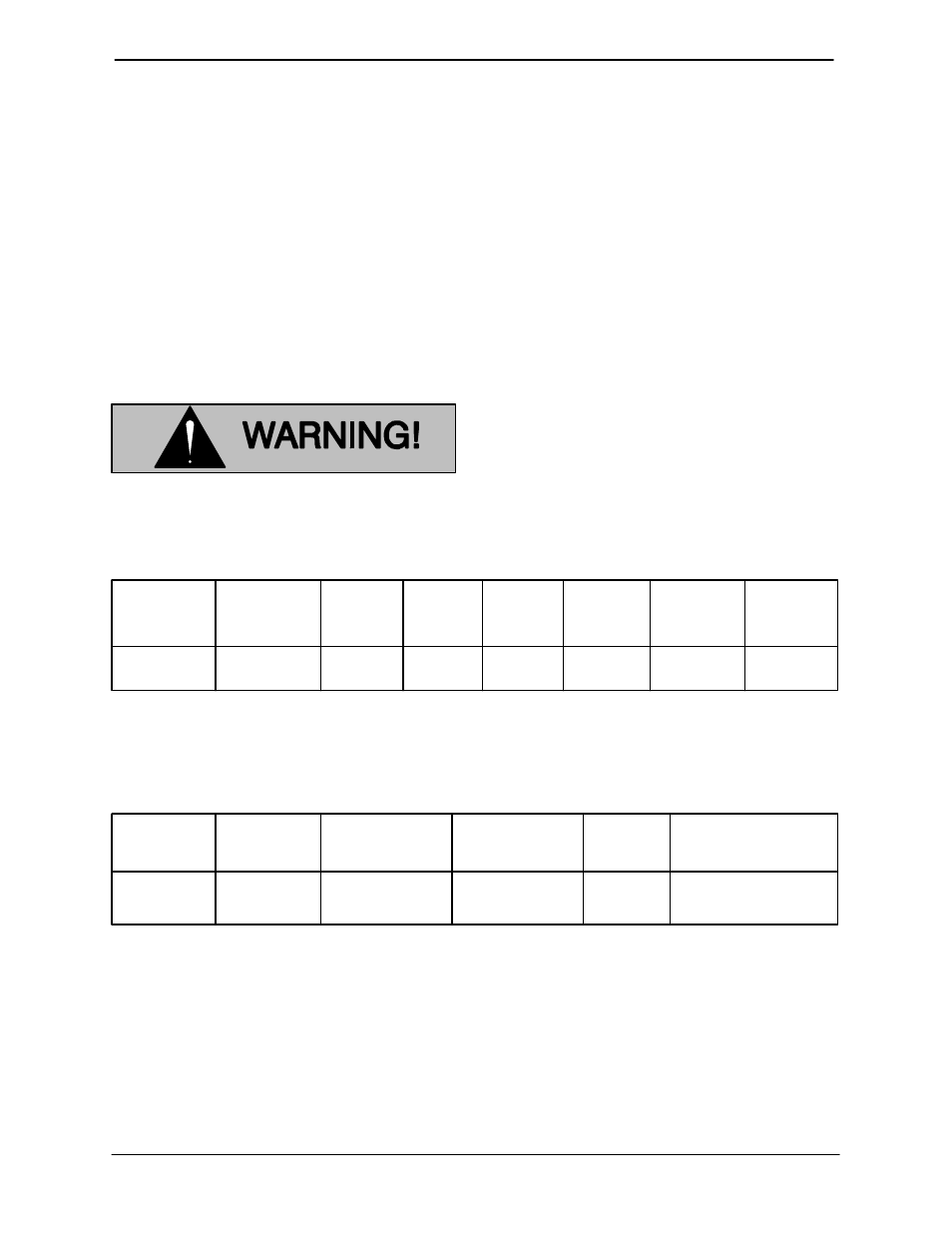

See Table 1 for typical pump specifications.

Table 1. Pump Specifications

Pump

Model

Voltage

Phase

kW

Motor

RPM

Cycle

Suction

Coupler

Discharge

Coupler

02K3

220

1

1.1

2900

50 Hz

1-1/2”

1-1/2”

See Table 1 for typical pump specifications.

Table 2. Unit Specifications

Power

Cable

Reel

Assembly

Suction

Hose

Ground

Wire

Standpipe Length

(Min) - (Max)

50 Ft.

(15,2 M.)

1-1/2” x 15 Ft.

38,1 MM x 4,6 M

10 Ft.

(3,1 M.)

42 Ft.

(12,8 M.)

Discharge

Hose

1-1/2” x 15 Ft.

38,1 MM x 4,6 M

7.25 Ft. - 12 Ft.

2,2 M - 3,7 M

Product Compatibility

The cleanout hose in the hose and reel assembly is

“Ambassador Hardwall 559N” hose manufactured

by Goodyear Tire and Rubber Company. It is com

patible with most hydrocarbon products. Consult

the Goodyear Tire and Rubber Company or

www.goodyear.com for specific product compati

bility.

Positioning Unit and Setup

Figure 2 shows a typical installation of the tank

leenor

t system.