Warning, Drafthood/damper installation, Flue outlet reducer – John Wood Commercial - AJWS User Manual

Page 8: Water system piping piping installation

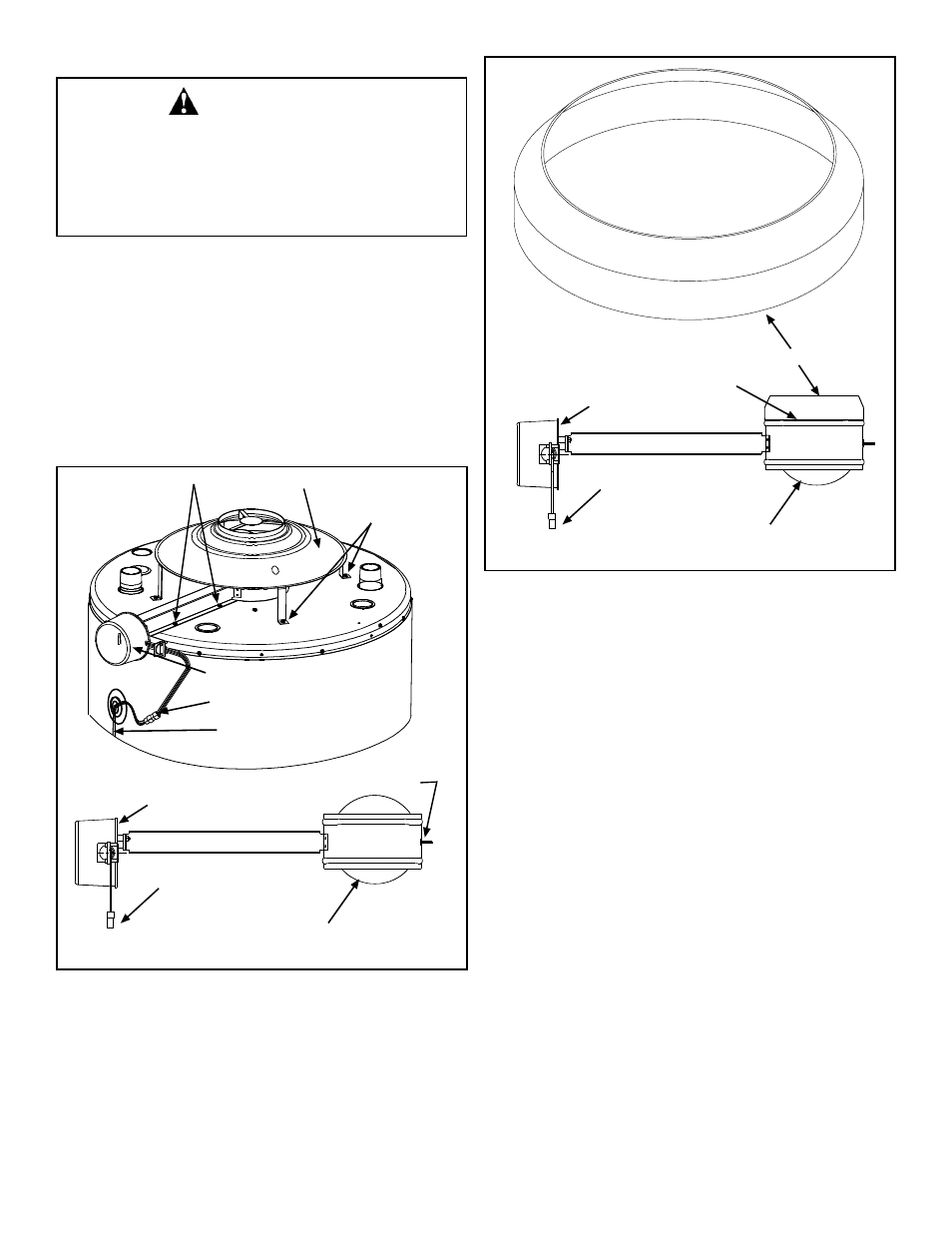

Drafthood/Damper Installation

Install the supplied drafthood and damper on the flue outlet

collar. Use only the supplied drafthood and damper, DO

NOT use any substitute or alter the components in any way.

Place the damper on the water heater (see figure 3A). Align

the four pilot holes on top of the water heater with the 4 cor-

responding holes on the damper bracket and secure with

the supplied screws. Next, align the drafthood legs with the

4 corresponding pilot holes on top of the water heater and

attach securely with the supplied screws. Locate the wiring

from the ECO, and attach it to the wiring harness on the

damper (see Figure 3A). Once damper is installed, ensure

that the damper position indicator is visible (See figure 3A).

Flue Outlet Reducer

Some units are shipped with a flue outlet reducer (See

Figure 3B). Use only the flue outlet reducer supplied with

this unit. The flue outlet reducer should be connected to the

top of the flue damper and sealed by high temperature sili-

con. The vent pipe must be installed according to all local

and state codes or, in the absence of local and state codes,

the “National Fuel Gas Code”, ANSI Z223.1(NFPA 54)-latest

edition. Canadian installations must be performed in accor-

dance with CAN/CSA-B149.1.

WATER SYSTEM PIPING

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (Figure 4). If the indoor installation

area is subject to freezing temperatures, the water piping

must be protected by insulation. Water supply pressure

should not exceed 80% of the working pressure of the water

heater. The working pressure is stated on the water heater’s

data plate. If this occurs, a pressure reducing valve with a

bypass should be installed in the cold water inlet line to the

entire system. This should be placed on the supply to the

entire structure in order to maintain equal hot and cold water

pressures.

Note: Water supplied to the unit that exceeds 12 grains

(205 mg/l) total hardness may reduce the life and perform-

ance of the water heater. Depending on the degree of hard-

ness, it is recommended that either a water pre-treatment

system or a water softener be installed and properly main-

tained.

Important: Heat cannot be applied to the water fittings on

the water heater as they may contain nonmetallic parts. If

solder connections are used, solder the pipe to the adapter

before attaching the adapter to the hot and cold water fit-

tings.

1.

The water heater may have three water piping connec-

tion points. The top and front are 1 - 1/2” NPT and the

connections on the back of some heaters are 2” NPT.

When using front or back connections a combination

nipple inlet tube is required (top entry uses a dip tube).

Any one of the options listed in Table 5 may be used.

For availability contact 1-888-479-8324.

8

Do not operate heater with damper in closed

position, it must be in the open position dur-

ing water heater operation. Do not negate

the action of any existing safety or opera-

tional controls.

WARNING

Bracket screws

Draft hood screws

Draft hood

Damper motor

Damper wiring harness

ECO wiring harness

Damper in OPEN position

Damper wiring harness

Damper motor

Damper position indicator

Figure 3A: Flue Damper Assembly

Damper in OPEN position

Damper wiring harness

Damper motor

Flue outlet reducer

High

temperature

silicon sealant

Figure 3B: Flue Outlet Reducer