Air opening requirements – John Wood Commercial - AJWS User Manual

Page 7

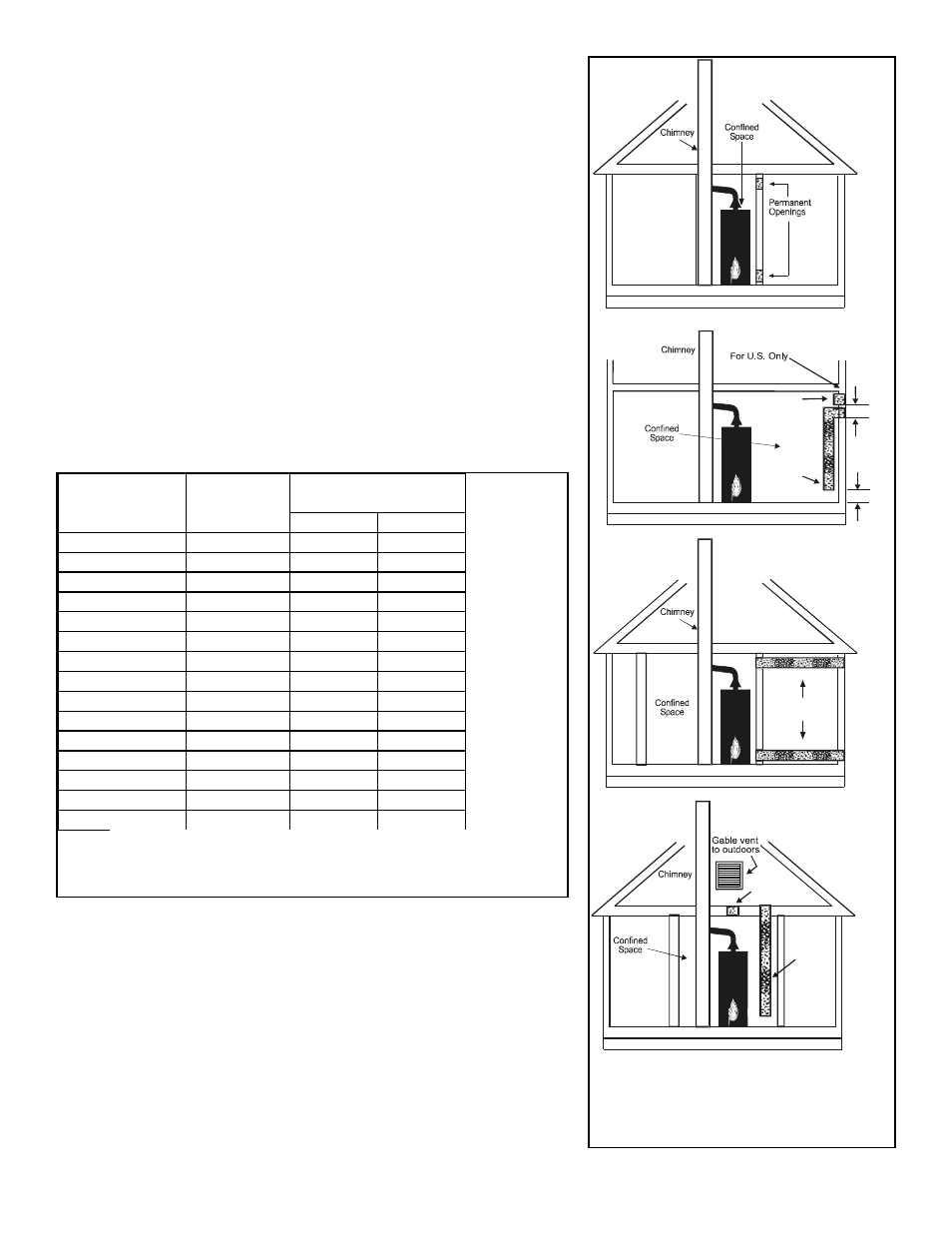

Air Opening Requirements

(a) EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM

INSIDE THE BUILDING.

Two permanent openings (top and bottom) shall be provided connecting

the confined space (e.g., closet/small room) with the unconfined space.

Each opening shall have a free area of one square inch per 1,000

BTU/hour (22 cm²/kW) input of all appliances in the confined space, but not

less than 100 square inches (645 cm²).

(b) BASEMENT INSTALLATION, EQUIPMENT LOCATED IN CONFINED

SPACES; ALL AIR FROM OUTDOORS.

Outside air inlets shall be a minimum of 305mm (12 in) above the grade

(snow) line. When supplying air directly from the outdoors:

For American installations: Two openings (top and bottom) shall be pro-

vided with each opening having a minimum free area of one square inch

per 4,000 BTU/hour input (5.5 cm²/kW) of total input rating of all appliances

in the confined space.

For Canadian installations: Canadian codes specify single air supply

source. Canadian customers and authorities having jurisdiction may use

the sizing listed in Table 1. When using a single air supply, the duct shall

terminate within 305mm (12 in) above and within 610mm (24 in) horizon-

tally from the burner level of the appliance having the largest input.

(c) EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM

OUTDOORS.

For American installations: When supplying air directly from the out-

doors using horizontal ducting, each opening shall have a free minimum

area of one square inch per 2,000 BTU/hour (11 cm²/kW) of total input rat-

ing of all appliances in the confined space.

For Canadian installations: Refer to Table 1 of part (b).

(d) EQUIPMENT LOCATED IN CONFINED SPACES; ALL AIR FROM

OUTDOORS THROUGH VENTILATED ATTIC.

For American installations: When supplying air directly through vertical

ducting, each opening shall have a free minimum area of one square inch

per 4,000 BTU/hour (5.5 cm²/kW) of total input rating of all appliances in

the confined space.

7

Combustion

Air Duct

Permanent

Ventilation

Air

12” Grade

12”

Outdoor

Air Ducts

Venting

Combustion

Inlet

Air Ducts

Outlet Air

(a)

(b)

(d)

(c)

Figure 2: Equipment Location and

Combustion/Ventilation Air

Requirements

*U.S. installations require a dual duct system.

A

1

B

2

BTU/h (kW)

mm2 (in2)

mm (in)

mm (in)

75,000 (23)

7,000 (11)

100 (4)

125 (5)

100,000 (30)

9,000 (14)

100 (4)

125 (5)

125,000 (37)

12,000 (18)

125 (5)

150 (6)

150,000 (45)

14,000 (22)

125 (5)

150 (6)

175,000 (53)

16,000 (25)

150 (6)

175 (7)

200,000 (60)

19,000 (29)

150 (6)

175 (7)

225,000 (68)

21,000 (32)

150 (6)

175 (7)

250,000 (75)

23,000 (36)

175 (7)

200 (8)

275,000 (83)

26,000 (40)

175 (7)

200 (8)

300,000 (90)

28,000 (43)

175 (7)

200 (8)

325,000 (98)

30,000 (47)

200 (8)

225 (9)

350,000 (105)

32,000 (50)

200 (8)

225 (9)

375,000 (113)

35,000 (54)

200 (8)

225 (9)

400,000 (120)

37,000 (58)

225 (9)

250 (10)

Com bined input of

all appliances in

confined space

Required free

area of duct

Acceptable equivalent

duct diam eter

Table 1

Notes:

1. Maximum length of ducts in column A is 6.1 equivalent metres (20 ft).

2. Maximum length of ducts in column B is 15.2 equivalent metres (50 ft).

305mm

(12 in)

305mm

(12 in)