Iii) vent connections – John Wood Direct Vent Models No Longer in Production User Manual

Page 4

III) VENT CONNECTIONS

After the location for the vent terminal has been selected

as outlined in Figure 3, use the following illustrations for

installation:

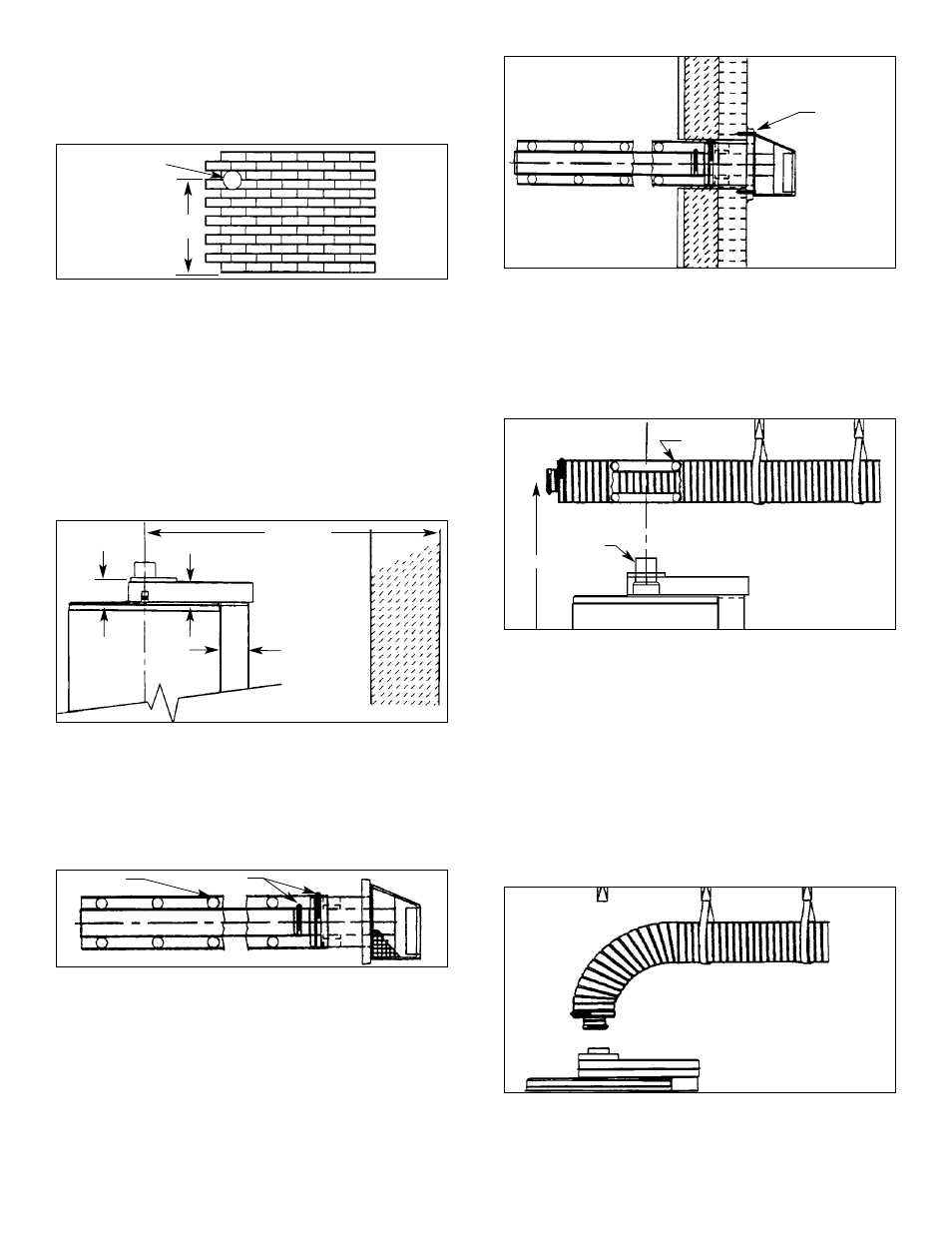

Figure 3A - Locating Clearance Hole For Vent.

Cut a clearance hole, approximately 178mm (7 in.) in

diameter, through the exterior wall for the vent assembly.

The minimum height should not be less than 1.72m (68 in.)

for Models 40BF and 50BF and not less than 1.93m (76

in.) for Model 50TBF, as measured from the hole center to

bottom of water heater. The maximum height recommend-

ed is 2.28m (90 in.) or in compliance with Figure 3M.

* Where the wall is combustible and the wall thickness is

over 356mm (14 in.), 25mm (1 in.) clearance to com-

bustible materials around the terminal pipe is needed. The

first 356mm (14 in.) is zero clearance.

Figure 3B - Moving Water Heater To Its Final Installed

Location.

Move the water heater to its final installed location. Make

certain clearances from combustible material are

observed. The maximum distance from center of water

heater to outside wall must not be more than 2.28m (90

in.).

Figure 3C - Vent Assembly.

The vent pipe and terminal are assembled by the manu-

facturer as shown in Figure 3C. There are springs fas-

tened inside the corrugated pipe. When the vent pipes

are pulled to a required length, the distances between the

springs will still be equally spaced.

Figure 3D - Securing Vent Termination Assembly To

The Exterior Wall.

Introduce the 152mm (6 in.) pipe through the clearance

hole from exterior wall then secure the vent terminal to

the exterior wall with 4 screw anchors appropriate for the

type of wall construction. Caulk the junction of the vent

terminal base plate and the exterior wall with exterior type

silicone sealant.

Figure 3E - Pull The 80mm (3-1/8 in.) And 152mm (6

in.) Corrugated Pipe Towards The Water Heater

Individually.

1. Pull the 80mm (3-1/8 in.) corrugated pipe towards the

water heater and leave some length over the water

heater’s center for bending.

2. Pull the 152mm (6 in.) corrugated pipe toward the

water heater and leave it 25mm (1 in.) shorter than

80mm (3-1/8 in.) pipe.

3. Make sure there are two springs evenly spaced at the

bend in the pipe.

4. Use metal hangers to keep vent pipe level or with a

slope upward from the heater to terminal.

Figure 3F

Bend the 80mm (3-1/8 in.) and 152mm (6 in.) corrugated

pipe all together toward the water heater’s flue connec-

tion.

- 4 -

178mm (7 in.)

DIAMETER

MINIMUM

(SEE TEXT)

BOTTOM OF HEATER

MAX. 2.28m

(90 in.)

76mm

(3 in.)

102mm

(4 in.)

102mm

(4 in.)

WALL

CLAMP

SPRING

SEALANT

REDUCER

H

SPRING