Xylem TB500 ONLINE TURBIDITY ANALYZERS User Manual

Page 32

TB500 (2/07)

Rev. 1.0

28

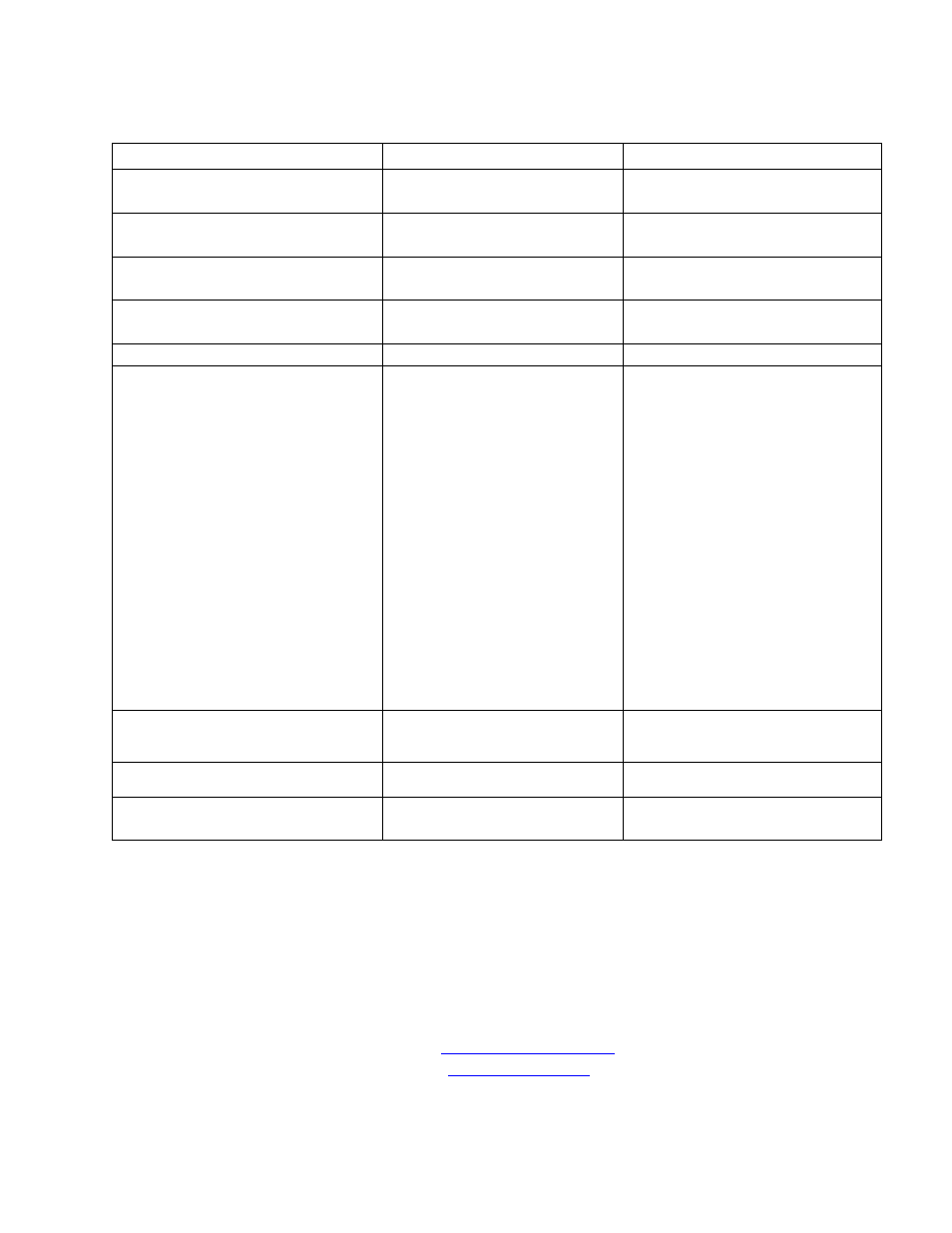

9.3 Diagnostic Chart

Symptom Cause Cure

Lower display shows MA

4-20 mA loop open

Check wiring. See sections

3.3.4 and 7.2

Lower display shows DESC

Desiccant pouch bad

Change desiccant pouch. See

section 10.2

Lower display shows LAMP

Lamp failed

Replace lamp. Refer to section

10.3

Lower display shows FLOW

Sample flow has stopped

Restore flow. Contact GW

about factory installed option

Lower display shows FAIL

Major system fault

Refer to section 9.1 & 9.2

Readings are higher than

expected

(1)

Bubbles in solution

(2)

Condensate or leaky

cuvette

(3)

Flow through cuvette

dirty

Instrument out of calibration

(1)

Ensure that the drain vent is

open and is not obstructed.

See section 3.2.2.

(2)

Apply backpressure. See

section 3.2 and figure 4

(3)

For sever cases of bubbles a

stilling chamber is

available. Call GW.

Part# 20106GW

Check flow through cuvette for

condensate or leaks.

Clean cuvette. See section 10.1

Recalibrate. Refer to section 5

Readings are erratic

(1)

Bubbles in solution

(2)

Debris in flow through

(1)

See above

(2)

Clean debris from cuvette

Readings are lower than expected Instrument out of calibration

Recalibrate. Refer to section 5

Upper display flashes

Sample Over-Range

Check sample. Sample may be

too high to read.

9.4 Technical and Customer Assistance

If for any reason assistance is needed regarding this instrument please do not hesitate to

contact Global Water’s Customer Service Department:

Global Water Instrumentation

11390 Amalgam Way

Gold River, CA 95670

Phone: (800) 876-1172

Fax: (847) 672-9988

Email:

www.globalw.com