Maintenance, Schedule – Xylem MM 307H Series 101-A Electric Water Feeder User Manual

Page 8

Xylem, Inc.

8200 N. Austin Avenue

Morton Grove, Illinois 60053

Phone: (847) 966-3700

Fax: (847) 965-8379

www.xyleminc.com/brands/mcdonnellmiller

McDonnell & Miller is a trademark of Xylem Inc. or one of its subsidiaries.

MAINTENANCE

SCHEDULE:

Annually

• Disassemble and inspect/clean strainer screen.

Replace if screen is torn or not able to be cleaned.

• Remove and inspect/clean cartridge.

Replace if

poppet does not move freely or debris cannot be

removed.

• Check all wires for brittle or worn insulation.

More frequent cleaning or replacement may be

required if used in locations where water treatment

is required or in applications with high make-up

water requirements.

Replace entire unit including equalizing piping every

10 years.

Replace control if it has been subjected to water from

a broken pipe or flooding.

NOTE

Use clean water to rinse components and surfaces. DO

NOT use sharp objects to scrape off any accumulations

of sediment or debris.

X

Z

TO BOILER

Feed�

Valve

By-Pass�

Valve

Check Valve

WATER�

SUPPLY

Make sure that the water level in the boiler is above the

closing level of the feeder.

Close valve 'X' and slowly open union 'Z' to determine if

valve is leaking.

• If water is leaking from the union, the valve needs

to be serviced.

• If no water leaks from the union, the feeder opera

tion is not the cause of the flooding.

Broken Union Test

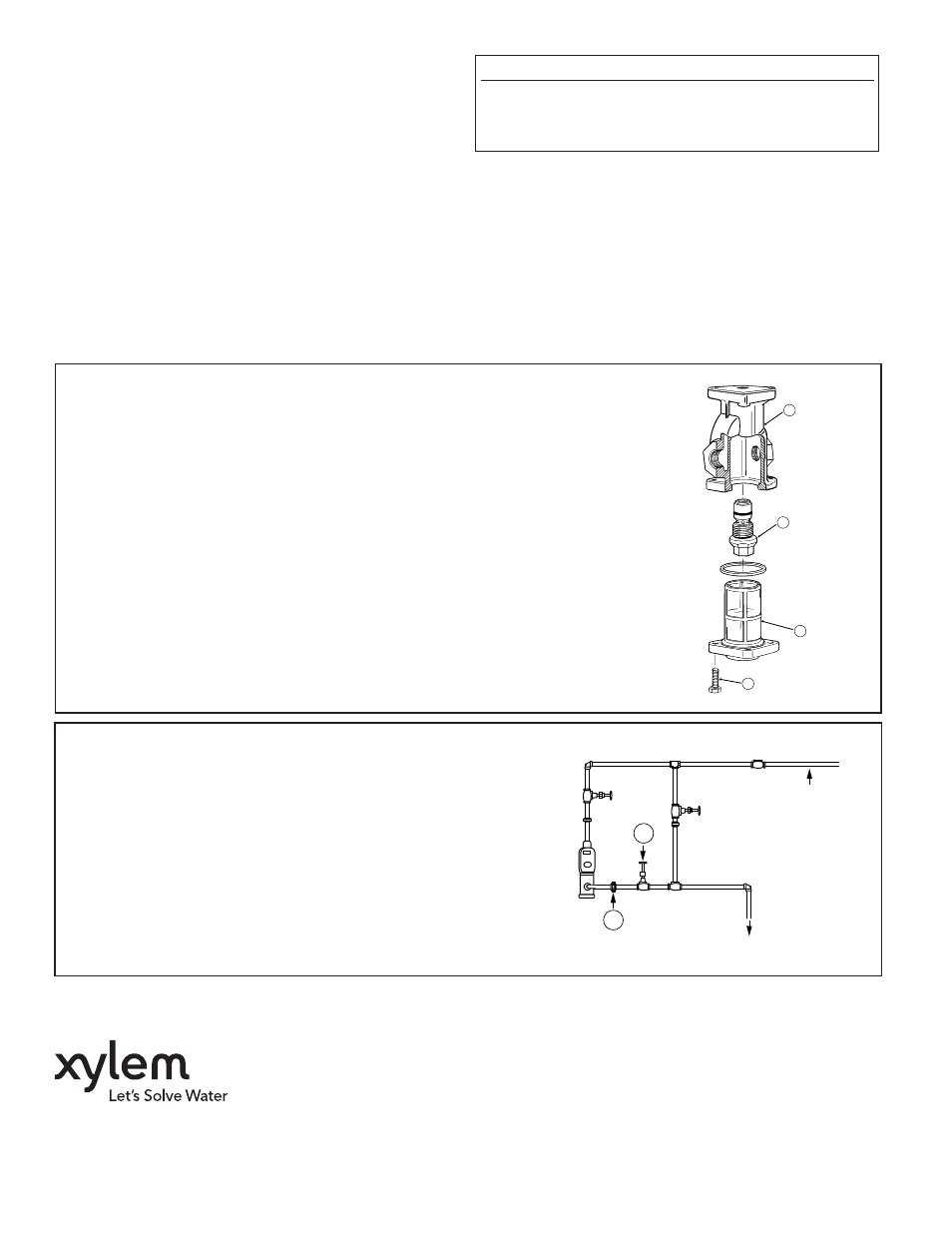

E

D

B

H

x 4

A. Using a 1/2" socket wrench, unscrew the four (4) hex-head

bolts (B) that secure the strainer basket (H) to the valve

assembly (E).

B. Using a 13/16" socket wrench, unscrew the cartridge (D)

and remove.

C. Clean any debris (scale, rust, etc.) from strainer and cartridge.

Poppet inside cartridge must move freely. Replace if debris

cannot be removed or poppet does not move freely.

D. Lubricate cartridge o-rings using silicone type lubricant and

re-install.

E. While depressing the manual feed (red) button, re-install the

cartridge and tighten 2 ft. lbs. (2.6 N•m). Do not over-tighten.

F. Re-install strainer basket. Tighten (4) bolts 8 ft. lbs. (11 N•m).

Removal of cartridge and strainer for inspection and cleaning

© 2013 Xylem Inc. MM-307H July 2013 Part No. 246761