Xylem SSW-07 Soft-Starter User Manual

Page 49

CHAPTER 6 - SOLUTION AND TROUBLESHOOTING

48

English

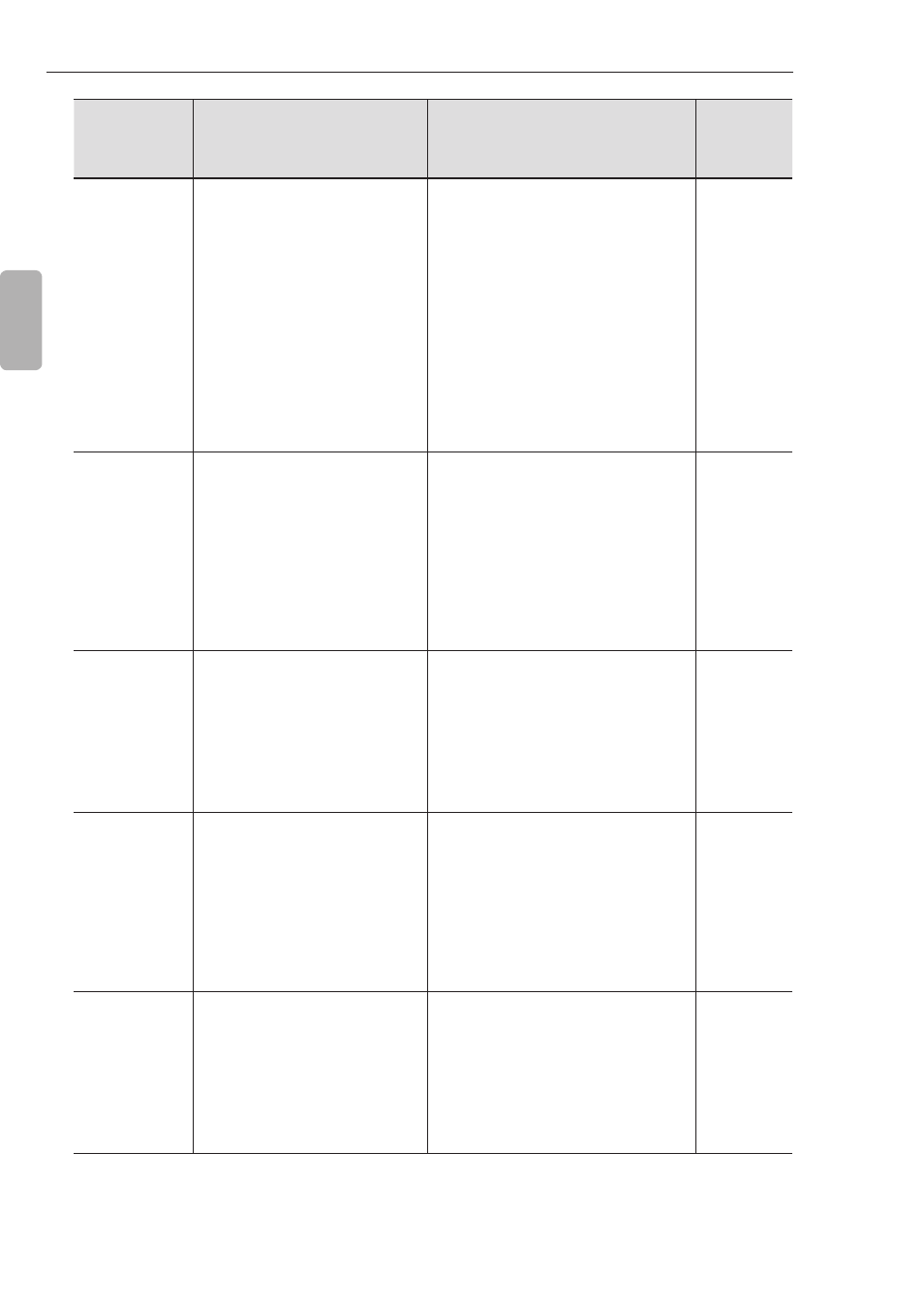

Protection

Description and

Fault Display

Activation Description

Probable Causes

Reset

Electronic

motor overload

E05

(LED Overload)

Flashing

When the times given by the

programmed thermal class

curves exceed the limit.

Incorrect setting of the "Motor

Current" trimpot (motor current set).

The set value is too low for the motor

being used.

Starting sequence greater than

allowed.

Programmed thermal class too low.

Time between Off/On procedures

lower than that permitted by the

motor power refrigeration time.

Load on the motor shaft too high.

Thermal protection value saved when

the control is turned off and brought

back when turned back on.

Power-on.

Reset key.

Auto-reset.

DIx.

Start timeout

during current

limit starting

E62

(LED Fault)

Flashes twice

(LED Ready)

On

When the starting time is

longer than the time set in the

acceleration ramp trimpot. Active

only with current limit starting.

Programmed time for the acceleration

ramp inferior to what is needed.

Value of the programmed current

limitation too low.

Motor locked, rotor blocked.

Power-on.

Reset key.

Auto-reset.

DIx.

Stall

E63

(LED Stall)

Flashing

Activates before full voltage, if

the current is greater than twice

the nominal motor current.

Programmed acceleration ramp time

lower than the actual acceleration

time.

Motor shaft is locked

The transformer that supplies the

motor can be saturating and taking

too much time to recover from the

starting current.

Power-on.

Reset key.

Auto-reset.

DIx.

Overcurrent

E66

(LED

Overcurrent)

Flashing

It is only monitored when the

SSW-07 is at full voltage. When

the parameters are set with

the factory default values this

protection trips when the motor

current exceeds 2 times the

value adjusted in the trimpot

(Motor Current) for a time longer

than 1 second.

Momentary motor overload.

Motor shaft is locked, rotor blocked.

Power-on.

Reset key.

Auto-reset.

DIx.

Incorrect phase

sequence

E67

(LED Phase

Seq.)

Flashing

When the sequence of

synchronism signals

interruptions does not follow the

RST sequence.

Network phase sequence inverted at

the input.

May have been changed in another

place of the supply network.

Motor connection is incorrect.

Power-on.

Reset key.

DIx.

table 6.1 - Faults and possible causes (cont.)