Terms and usable formulas – Xylem Wastewater (Technical Manual) User Manual

Page 15

PAGE 15

Wastewater

Goulds Water Technology, Bell & Gossett,

Red Jacket Water Products, CentriPro

BASIC FORMULAS AND SYMBOLS

The term “head” by itself is

rather misleading. It is com-

monly taken to mean the dif-

ference in elevation between

the suction level and the

discharge level of the liquid

being pumped. Although this

is partially correct, it does not

include all of the conditions

that should be included to give

an accurate description.

■

Friction Head:

The pressure expressed in

lbs./sq. in. or feet of liquid

needed to overcome the

resistance to the flow in the

pipe and fittings.

■

Suction Lift: Exists when

the source of supply is

below the center line of the

pump.

■

Suction Head: Exists when

the source of supply is

above the center line of the

pump.

■

Static Suction Lift:

The vertical distance from

the center line of the pump

down to the free level of the

liquid source.

■

Static Suction Head:

The vertical distance from

the center line of the pump

up to the free level of the

liquid source.

■

Static Discharge Head: The

vertical elevation from the

center line of the pump to

the point of free discharge.

■

Dynamic Suction Lift:

Includes static suction lift,

friction head loss and veloc-

ity head.

■

Dynamic Suction Head:

Includes static suction head

minus friction head minus

velocity head.

■

Dynamic Discharge Head:

Includes static discharge

head plus friction head plus

velocity head.

■

Total Dynamic Head:

Includes the dynamic

discharge head plus dy-

namic suction lift or minus

dynamic suction head.

■

Velocity Head: The head

needed to accelerate the

liquid. Knowing the velocity

of the liquid, the velocity

head loss can be calculated

by a simple formula Head =

V

2

/2g in which g is accelera-

tion due to gravity or 32.16

ft./sec. Although the velocity

head loss is a factor in figur-

ing the dynamic heads, the

value is usually small and in

most cases negligible.

See table.

Formulas

GPM =

Lb./Hr.

500 x Sp. Gr.

H

=

2.31 x psi

Sp. Gr.

H

= 1.134 x In. Hg.

Sp. Gr.

H

V

= V

2

= 0.155 V

2

2g

V = GPM x 0.321 = GPM x 0.409

A

(I.D.)

2

BHP = GPM x H x Sp. Gr.

3960 x Eff.

Eff. = GPM x H x Sp. Gr.

3960 x BHP

N

S

= N√GPM

H

3/4

H = V

2

2g

Symbols

GPM = gallons per minute

Lb.

= pounds

Hr.

= hour

Sp. Gr. = specific gravity

H

= head in feet

psi

= pounds per square inch

In. Hg. = inches of mercury

h

v

= velocity head in feet

V

= velocity in feet per second

g

= 32.16 ft./sec.

2

(acceleration of gravity)

A = area in square inches (πr

2

)

(for a circle or pipe)

ID = inside diameter in inches

BHP = brake horsepower

Eff. = pump efficiency

expressed as a decimal

N

S

= specific speed

N = speed in revolutions

per minute

D = impeller in inches

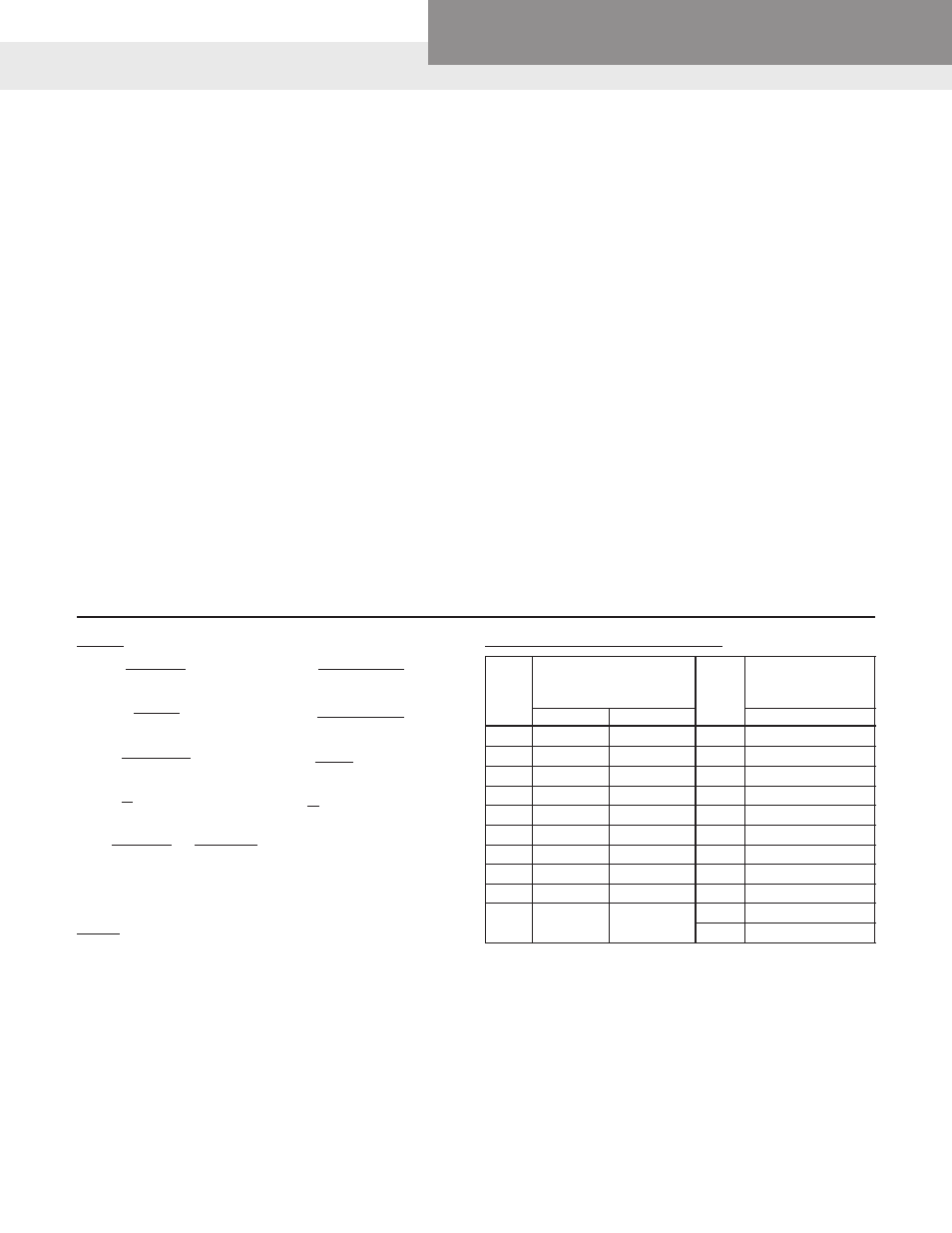

Approximate Cost of Operating Electric Motors

*Average kilowatts input

*Av. kw input or cost

Motor

or cost based on 1 cent

Motor

per hr. based on

HP

per kilowatt hour

HP

1 cent per kw hour

1 Phase

3 Phase

3 Phase

1

⁄

3

.408

20

16.9

1

⁄

2

.535

.520 25

20.8

3

⁄

4

.760

.768 30

26.0

1

1.00

.960

40

33.2

1

1

⁄

2

1.50

1.41 50

41.3

2

2.00

1.82

60

49.5

3

2.95

2.70

75

61.5

5

4.65

4.50

100

81.5

7

1

⁄

2

6.90

6.75 125

102

10 9.30

9.00

150

122

200

162

Terms and Usable Formulas