H-312 – Xylem H-312-22 User Manual

Page 19

H-312

Maintenance 3-3

CAUTION:

Do not use sticks and the like to push sediment out of the ports. This may

cause a hydraulic effect and over pressure the internal sensor. Use common

sense.

Step 5 Reinstall the plastic and the stainless steel screens. Position the joints of the stainless and

plastic screens 180 apart. One end of the stainless steel screen has a slight bend. Position

the bent end on the outside to help keep the sharp end from protruding out. Compress the

screen with a turning action and slip both screens into the shallow groove in the sensor

housing..

Step 6 Screw the nose piece into place until it contacts the screens. Twist the screens until both

screens slip into the grooves of both the sensor housing and the nose piece. Continue to

tighten the nose piece while being careful to not crinkle the screens. You may need to

twist the screens now and then to keep the screens centered in the grooves. Fully hand

tighten the nose piece.

3.5 Trouble Shooting

Experience over the years with submersible sensors has identified several common problems:

No SDI-12 response or intermittent data

1.

Check all wiring including power and ground connections. Battery connections can

become corroded.

2.

The H-312 measures and reports it’s internal power supply voltage along with

Stage and Pressure. Make a measurement and check to see if the voltage is

between 10.0 and 16.0 Volts.

3.

Check the connections between your data recorder and the H-312 sensor.

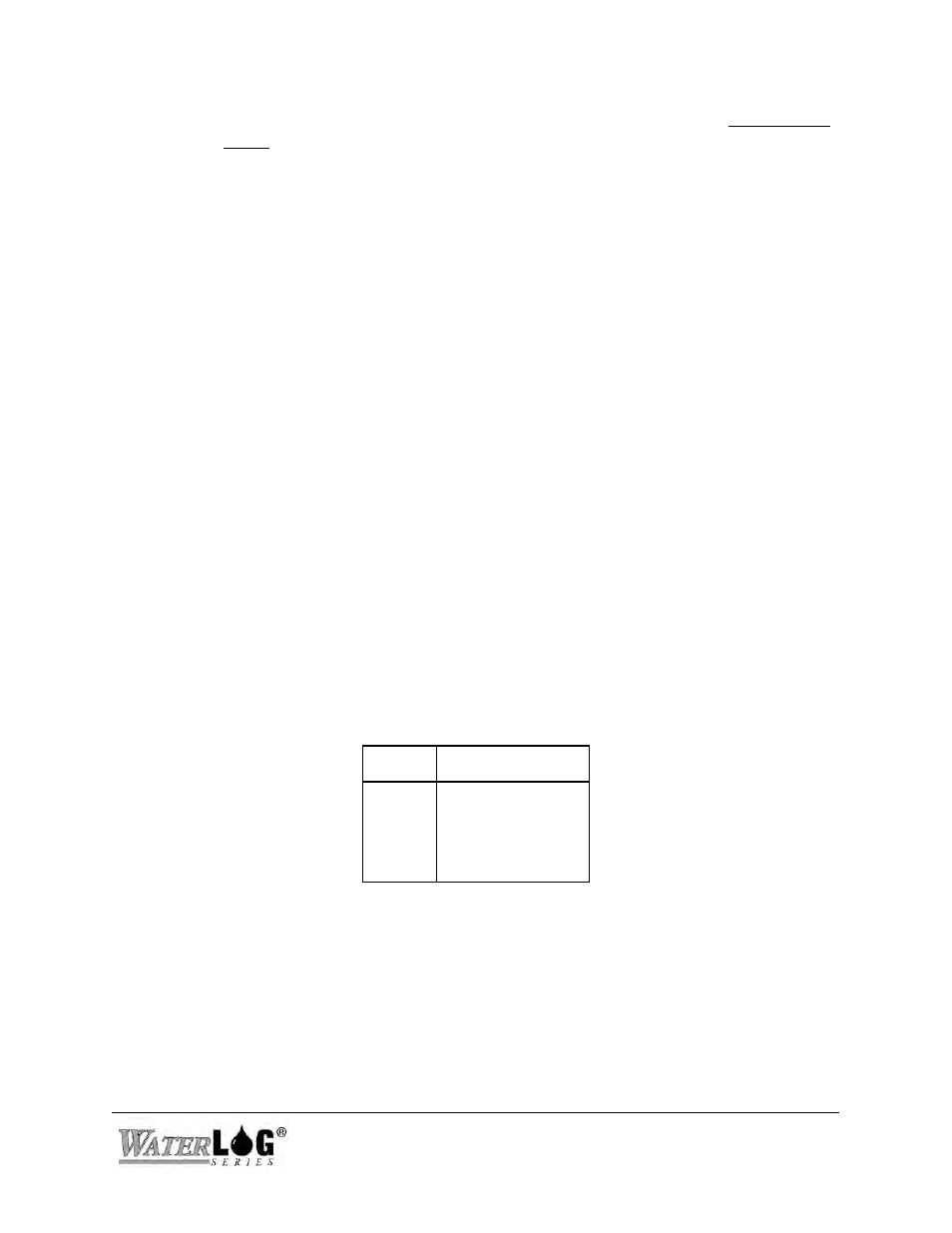

Wire

Name

Red

White

Black

Shield

+12Volt DC

SDI-12 Data

Ground

Ground

Offset Drift

Check the desiccant packs. If moisture accumulates in or blocks the vent tube, barometric

pressure changes will affect the pressure measurement. If this is the case, you should contact

Design Analysis for instructions as how to proceed.