H-312 – Xylem H-312-22 User Manual

Page 18

3-2 Maintenance

H-312

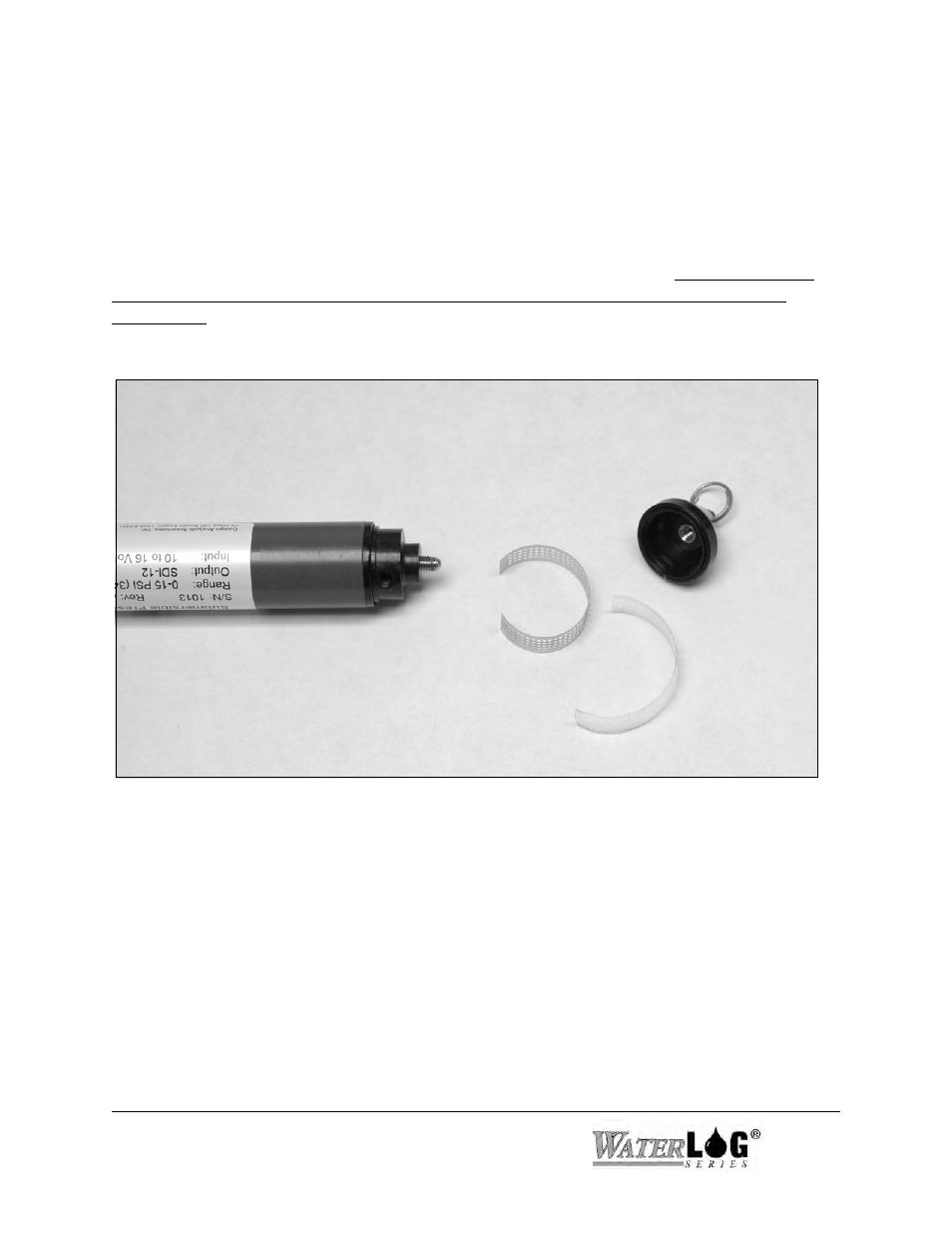

Figure 9 Cleaning the Port Screen

3.4 Cleaning the Port Screen

The H-312 has a port screen to help prevent dirt, sediment and insects from entering the sensor

pressure port. The screen is a circular stainless steel band with .025 square holes. A 149 micron

polypropylene plastic screen is located underneath the stainless screen.

Occasionally the port screen and the pressure ports may need to be cleaned, rinsed out or replaced

. Replacement stainless steel and polypropylene screens are available if needed. The photo below

shows the dissembled components at the bottom end of the sensor housing. Do not remove the

rubber grommet on the cable end of the sensor housing, the snap-ring or any of the internal

components. If the sensor is disassembled the pressure sensor generally must be re-calibrated at

the factory. To service the port screen perform the following steps.

Step 1 Unscrew the lower end-piece from the sensor housing (the tapered end cap).

Step 2 Remove the stainless and polypropylene screens.

Step 3 Clean or replace the screens as needed.

Step 4 The internal nose of the H-312 has two threaded pressure ports located 180 apart. These

ports are used in the factory to make connections in the calibration oven. Rinse the

pressure ports with water to clear mud and silt. You may want to swish the sensor in a

bucket of water or in the stream it is monitoring to rinse out the pressure ports.