Xylem e-SV User Manual

Page 19

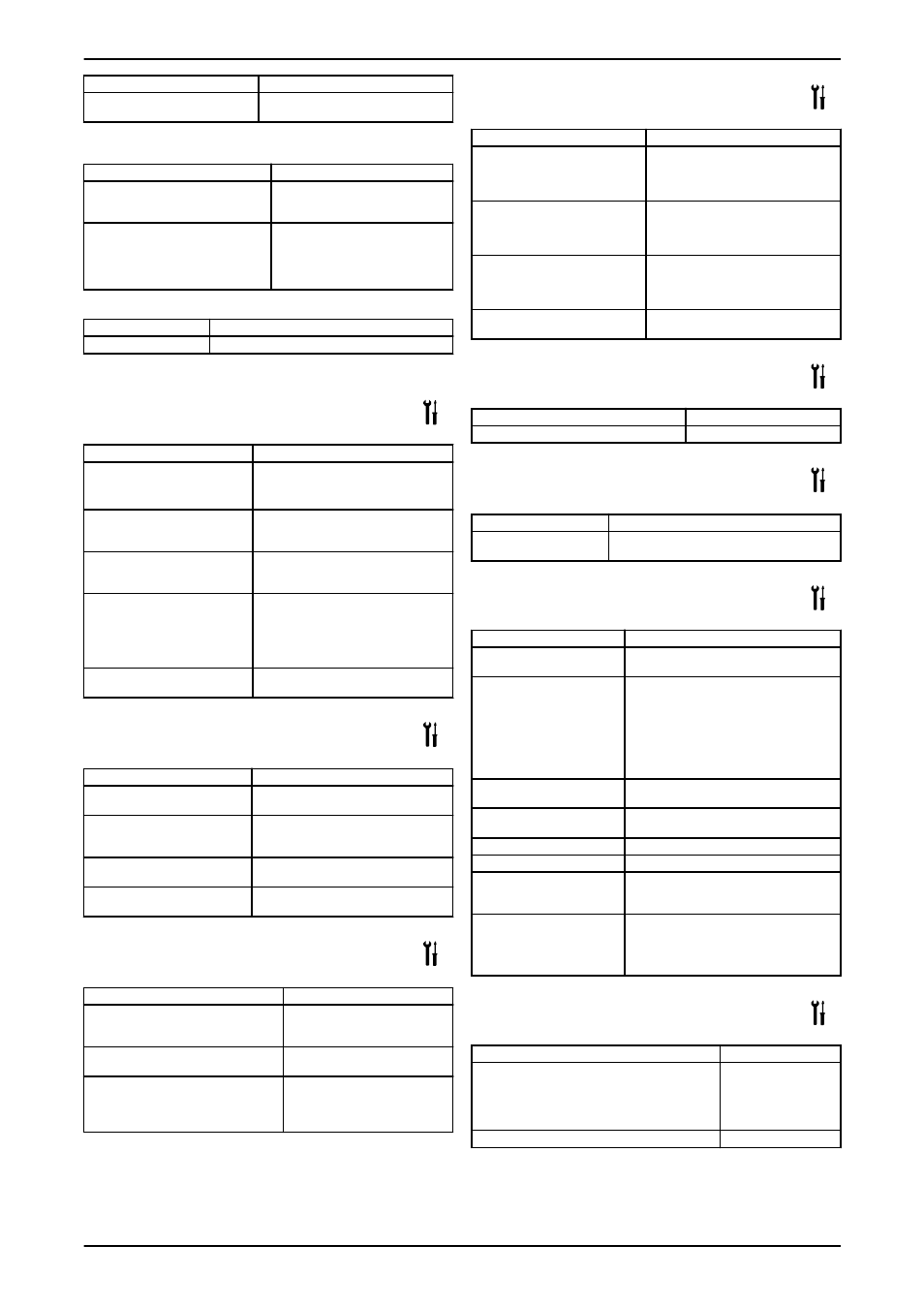

Cause

Remedy

The protective device against dry

running has tripped.

Check the water level in the tank, or

the mains pressure.

The electric pump starts, but the thermal protection trips a varying time af-

ter.

Cause

Remedy

There are foreign objects (solids or fi-

brous substances) inside the pump

which have jammed the impeller.

Contact the Sales and Service De-

partment.

The pump is overloaded because it is

pumping liquid that is too dense and

viscous.

Check the actual power require-

ments based on the characteristics

of the pumped liquid and then con-

tact the Sales and Service Depart-

ment.

The pump runs but delivers too little or no water.

Cause

Remedy

The pump is clogged.

Contact the Sales and Service Department.

The troubleshooting instructions in the tables below are for installers only.

7.2 The main switch is on, but the electric

pump does not start

Cause

Remedy

There is no power supply.

• Restore the power supply.

• Make sure all electrical connections

to the power supply are intact.

The thermal protector incorpora-

ted in the pump (if any) has trip-

ped.

Wait until the pump has cooled down.

The thermal protector will automatically

reset.

The thermal relay or motor pro-

tector in the electric control panel

has tripped.

Reset the thermal protection.

The protective device against dry

running has tripped.

Check the:

• water level in the tank, or the mains

pressure

• protective device and its connecting

cables

The fuses for the pump or auxili-

ary circuits are blown.

Replace the fuses.

7.3 The electric pump starts, but the

thermal protector trips or the fuses blow

immediately after

Cause

Remedy

The power supply cable is dam-

aged.

Check the cable and replace as necessa-

ry.

The thermal protection or fuses

are not suited for the motor cur-

rent.

Check the components and replace as

necessary.

The electric motor is short cir-

cuit.

Check the components and replace as

necessary.

The motor overloads.

Check the operating conditions of the

pump and reset the protection.

7.4 The electric pump starts, but the

thermal protector trips or the fuses blow a

short time after

Cause

Remedy

The electrical panel is situated in an ex-

cessively heated area or is exposed to di-

rect sunlight.

Protect the electrical panel from

heat source and direct sunlight.

The power supply voltage is not within

the working limits of the motor.

Check the operating conditions of

the motor.

A power phase is missing.

Check the

• power supply

• electrical connection

7.5 The electric pump starts, but the

thermal protector trips a varying time after

Cause

Remedy

There are foreign objects (solids or

fibrous substances) inside the

pump which have jammed the im-

peller.

Contact the Sales and Service Depart-

ment.

The pumps delivery rate is higher

than the limits specified on the da-

ta plate.

Partially close the on-off valve down

stream until the delivery rate is equal or

less than the limits specified on the da-

ta plate.

The pump is overloaded because it

is pumping liquid that is too dense

and viscous.

Check the actual power requirements

based on the characteristics of the

pumped liquid and replace the motor

accordingly.

The motor bearings are worn.

Contact the Sales and Service Depart-

ment.

7.6 The electric pump starts, but the

system's general protection is activated

Cause

Remedy

A short circuit in the electrical system.

Check the electrical system.

7.7 The electric pump starts, but the

system's residual current device (RCD) is

activated

Cause

Remedy

There is an earth (ground)

leakage.

Check the insulation of the electrical system

components.

7.8 The pump runs but delivers too little or

no water

Cause

Remedy

There is air inside the pump

or the piping.

• Bleed the air

The pump is not correctly

primed.

Stop the pump and repeat the prime proce-

dure. If the problem continues:

• Check that the mechanical seal is not

leaking.

• Check the suction pipe for perfect tight-

ness.

• Replace any valves that are leaking.

The throttling on the delivery

side is too extensive.

Open the valve.

Valves are locked in closed or

partially closed position.

Disassemble and clean the valves.

The pump is clogged.

Contact the Sales and Service Department.

The piping is clogged.

Check and clean the pipes.

The rotation direction of the

impeller is wrong (three-phase

version).

Change the position of two of the phases

on the terminal board of the motor or in

the electric control panel.

The suction lift is too high or

the flow resistance in the suc-

tion pipes is too great.

Check the operating conditions of the

pump. If necessary, do the following:

• Decrease the suction lift

• Increase the diameter of the suction pipe

7.9 The electric pump stops, and then

rotates in the wrong direction

Cause

Remedy

There is a leakage in one or both of the following

components:

• The suction pipe

• The foot valve or the check valve

Repair or replace the

faulty component.

There is air in the suction pipe.

Bleed the air.

en - Translation of the original instructions

e-SV - English

15