Xylem 4OS User Manual

Page 9

9

2.

Product Description

Information for installers and users

The 4OS range comprises a number of 4” submersible motors with stator and rotor in cooling filling fluid suitable for use with foodstuffs,

designed to be coupled to 4” and 6” submersible pumps with NEMA-compliant flange and coupling sizes.

All the metal parts in contact with the water are either made from stainless steel or brass alloy.

Each motor includes a cable with removable connector.

3.

Applications

Information for installers and users

All the motors in the 4OS range can be used to drive submersible pumps in the conditions established in EN 60034-1 (IEC 60034-1) and at the

supply voltage / frequency specified on the rating plate.

The shaft extension and flange size of these motors comply with NEMA MG1.

The power of the pumps coupled to these motors must be less than or equal to that of the motors.

3.1

Working Limits

3.1.1

Liquids in which the motor can operate

This motor can be used in cold water.

Do not use this motor with corrosive or explosive liquids, or particularly dirty or hard water (impurities may deposit on

the outer casing).

3.1.2

Water temperature

Minimum water temperature is + 0°C.

Maximum water temperature is + 35°C as long as the flowrate of the water around the motor does not fall below 0.08

m/s.

For temperatures above + 35°C, motor output must be reduced to ensure correct cooling.

For further information, please contact our Sales and Service Department.

3.1.3

Cooling the motor

To ensure the motor is correctly cooled, make sure the flowrate of the water around the outer casing is at least 0.08

m/s when positioning the motor in wells or tanks. At water speeds lower than 0.08 m/s, mount a cooling jacket.

For further information, please contact our Sales and Service Department.

3.1.4

Installation Position

All the motors in the range can be installed vertically.

Motors with up to 2.2 kW power can be installed horizontally. For higher powered motors, horizontal installation is possible only if the motor has

three points of support: at both ends and in the middle.

For special requirements, please contact our Sales and Service Department.

3.1.5

Depth of immersion

The maximum depth of immersion for all motors is 150 m.

3.1.6

Power supply requirements

Make sure the supply voltage and frequency match those indicated on the rating plate of the motor.

For further information, please contact our Sales and Service Department.

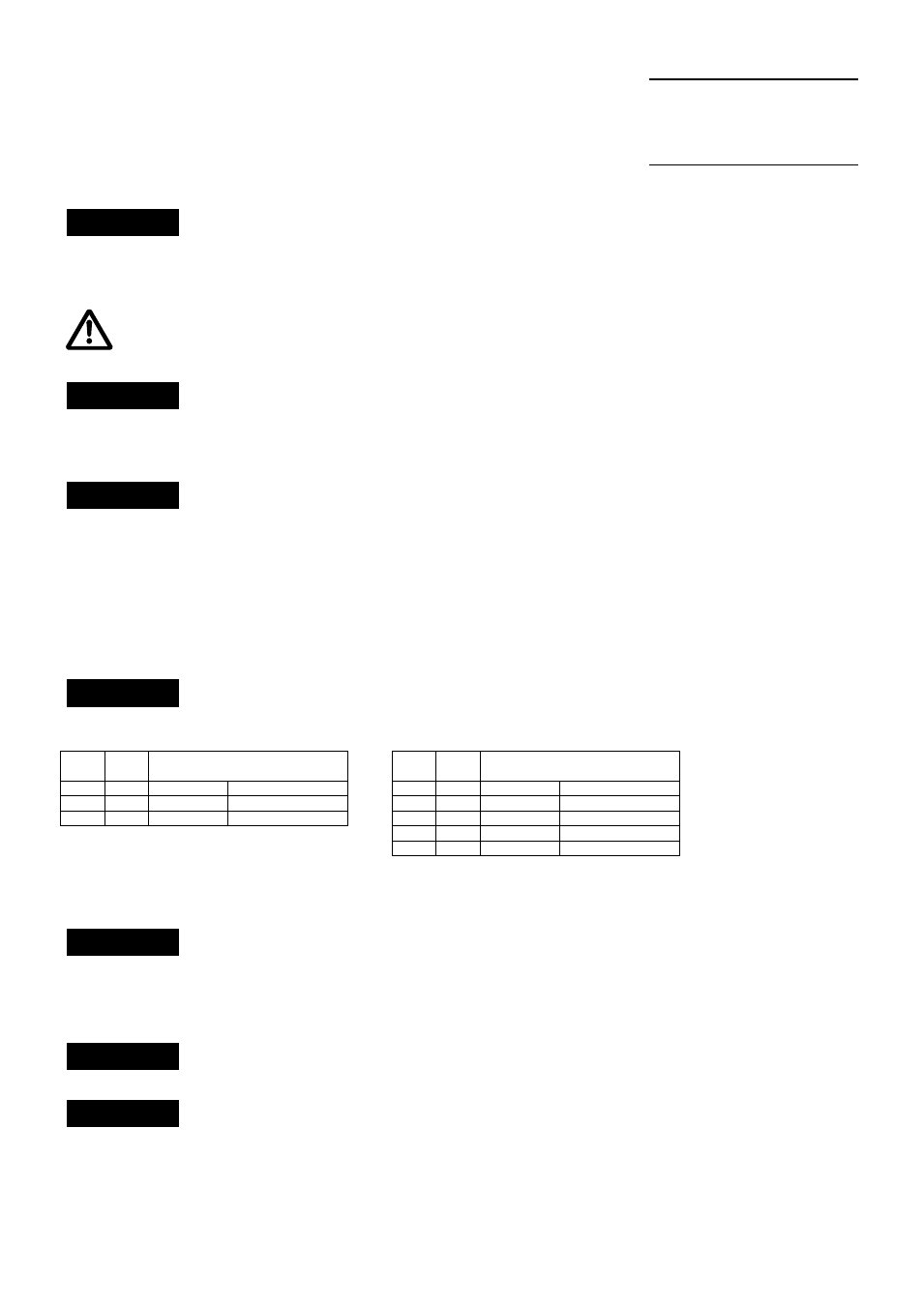

The motors can generally work at the following supply voltage tolerances:

f

UN

f

UN

Hz

~

V

± %

Hz

~

V

± %

50

1

220ч240

230 ± 10%

60

1

110ч115

110 ± 10%

50

3

220ч240

230 ± 10%

60

1

220ч230

220 ± 10%

50

3

380ч415

400 ± 10%

60

3

220ч230

220 ± 10%

60

3

380

380 ± 10%

60

3

460

460 ± 10%

3.1.7

Number of starts per hour

The maximum number of starts per hour is 30 for direct starting and 20 for impedance starting.

3.1.8

Compatible pumps

Make sure the motor is compatible with the pump. Incompatible combinations may cause problems.

In particular, before coupling the motor to the pump check that:

- the power of the pump to couple to the motor is less than or equal to that of the motor.

- the supply voltage and frequency match those indicated on the rating plate of the motor

- the motor and pump shafts turn freely

For further information, please contact our Sales and Service Department.

3.1.9

Motor powered by a frequency converter

Only specially ordered motors can be powered with a frequency converter.

For further information, please contact our Sales and Service Department.

If the motor is combined with a frequency converter, downgrade power by 10% and make sure you never exceed the

rated input frequency of the motor.

To ensure the motor is properly cooled, the minimum water flowrate at the minimum frequency of use must equal the

minimum flowrate indicated in the previous points.

For further information, please contact our Sales and Service Department.

3.1.10

Motor powered by a generating set

For information, please contact our Sales and Service Department.

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING