Xylem IMDWT R02 Model DWT Deep Well Turbine Pumps User Manual

Page 22

22

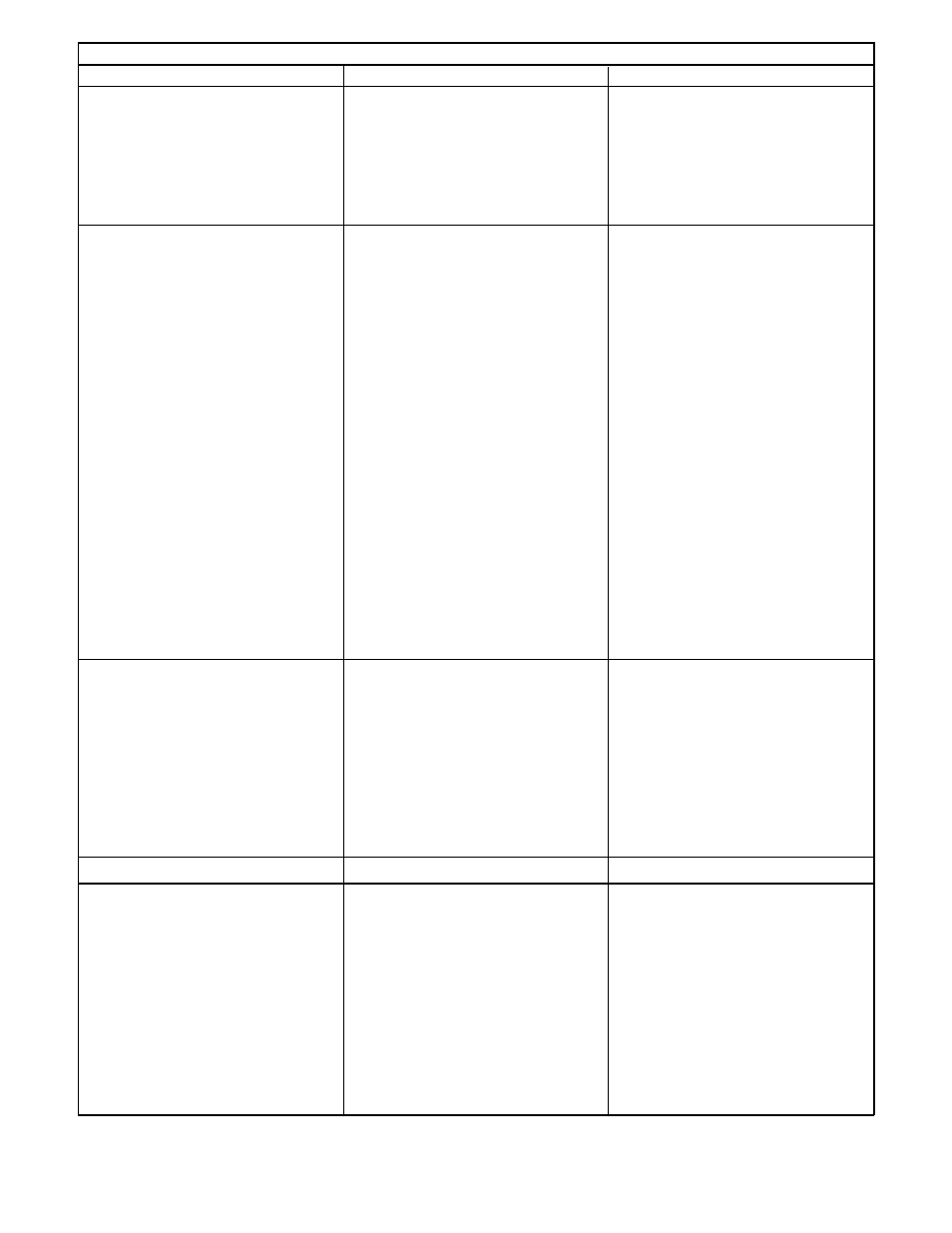

TroUBLESHooTING

TroUBLE

ProBABLE CAUSE

rEMEdY

1. Pump does not start

A. Electrical circuit open or not

Check circuit and correct.

completed

B. Improper lateral adjustment.

Reset impeller adjustment,

Impeller on bottom.

See page 16.

C. Low voltage supplied to

Check whether driver wiring is

electric driver

correct and receives full voltage.

D. Defective motor

Consult factory.

2. No liquid delivered

A. Discharge valve closed

Be sure the discharge valve is in

full open position.

B. Speed is too low

Check if driver is directly across

the line and receiving full voltage.

C. Wrong rotation

Check for CCW rotation when

viewed from above. Check

engagement of motor coupling.

D. Obstruction in liquid passage

Pull pump, inspect suction

strainer, impeller and bowls.

E. Water level in the well is below

Increase pump setting by adding

1

st

stage impeller

column.

F. Static lift too high

Check the dynamic water level in

well. Consult factory for adding

stages or increase impeller diam.

G. Field head requirement greater

Check system friction loss.

than design head

Increase discharge piping size.

Consult factory for adding stages

or increase impeller diameter

H. Damaged bowl assembly;

Pull pump and repair all

Broken or disconnected shaft

damaged components.

I. Driver with reduced voltage, or

Check RPM, voltage and amp’s.

reduced current starting does

not come up to speed

3. Not enough liquid

A. Same as items 2-A thru 2-G

Same as items 2-A thru 2-G.

B. Cavitation

Insufficient NPSH available.

Consider to low the bowl

assembly by adding column.

C. Impellers adjusted too high

See page 16.

D. Air or gas in the water

If successive starts and stops

does not remedy, low pump if

possible, or close discharge

valve to maintain well pumping

level at a lower GPM.

E. Excessive pump wear

Pull pump and repair as required.

4. Not enough pressure

See not enough liquid.

See not enough liquid.

5. Pump works for a while

A. Excessive horsepower required.

Use larger driver. Consult factory.

and quits

B. Pumping higher viscosity or

Test liquid for viscosity and

specific gravity liquid than

specific gravity.

designed for.

C. Mechanical failure of

Check bearings and impellers for

critical parts

damage. Any irregularities in

these parts will cause a drag

on the shaft.

D. Suction strainer clogged

Pull pump and clean the strainer.

E. Misalignment

Realign pump and driver

F. Break suction

Check dynamic water level in the

well. Lower bowl assembly by

adding column.