Introduction, Safety instructions, Performance pre-installation checks – Xylem IM248R01 High Temp Sump Pump User Manual

Page 3

3

0

10

20

30

40

50

60

70

80

GPM

0

0

10

10

0

20

30

m

3

/hr

5

10

40

METERS FEET

TOT

AL

D

YNAMIC HEAD

CAPACITY

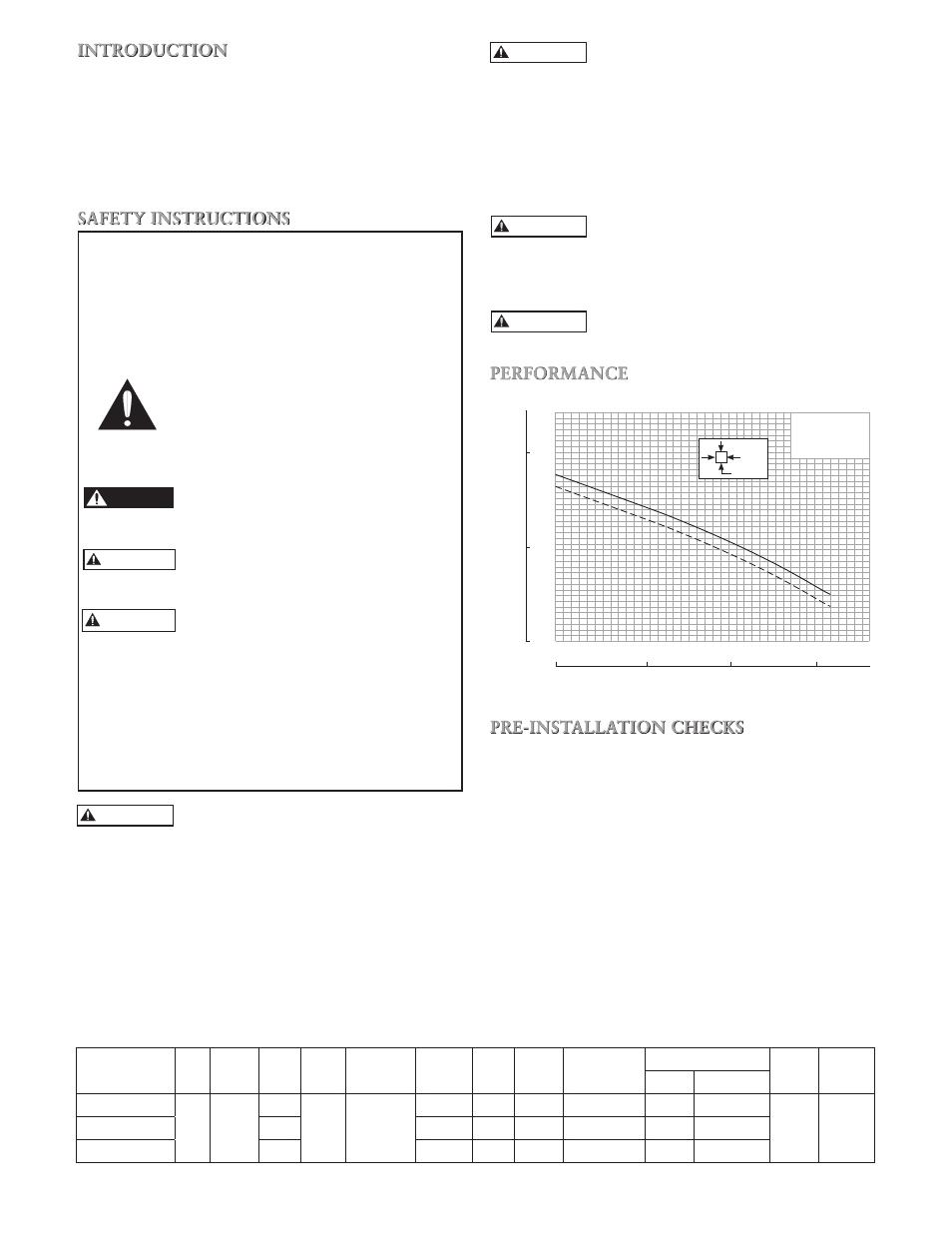

MODEL: WEHT03xxM

SIZE: 2" Discharge

RPM: 1750

HP: .33 HP

SOLIDS:

3

/

4

" Diameter

15

5

5

15

25

35

WEHT03M

1 FT

2 GPM

Derate at

200ºF (93ºC)

68ºF (20ºC)

INTRODUCTION

Goulds Water Technology High Temperature 3885 Series

Effluent pumps are recommended for use in High Tem-

perature applications up to 200ºF. The High Tempera-

ture 3885 Pump handles ¾” solids . Common applica-

tions include boiler blow down and High Temperature

condensate. Pump should be operated with a High

Temperature float switch sold separately.

SAFETY INSTRUCTIONS

TO AVOID SERIOUS OR FATAL PERSONAL

INJURY OR MAJOR PROPERTY DAMAGE, READ

AND FOLLOW ALL SAFETY INSTRUCTIONS IN

MANUAL AND ON PUMP.

THIS MANUAL IS INTENDED TO ASSIST IN THE

INSTALLATION AND OPERATION OF THIS UNIT

AND MUST BE KEPT WITH THE PUMP.

This is a SAFETY ALERT SYMBOL.

When you see this symbol on the pump

or in the manual, look for one of the

following signal words and be alert

to the potential for personal injury or

property damage.

Warns of hazards that WILL cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause

serious personal injury, death or major

property damage.

Warns of hazards that CAN cause per-

sonal injury or property damage.

NOTICE: INDICATES SPECIAL INSTRUCTIONS

WHICH ARE VERY IMPORTANT AND

MUST BE FOLLOWED.

THOROUGHLY REVIEW ALL INSTRUCTIONS

AND WARNINGS PRIOR TO PERFORMING ANY

WORK ON THIS PUMP.

MAINTAIN ALL SAFETY DECALS.

All electrical work must be performed

by a qualified technician. Always follow

the National Electrical Code (NEC), or the Canadian

Electrical Code, as well as all local, state and provincial

codes. Code questions should be directed to your local

electrical inspector. Failure to follow electrical codes and

OSHA safety standards may result in personal injury or

equipment damage. Failure to follow manufacturer’s

installation instructions may result in electrical shock, fire

hazard, personal injury or death, damaged equipment,

provide unsatisfactory performance, and may void manu-

facturer’s warranty.

DANGER

WARNING

CAUTION

Standard units are not designed for use in

swimming pools, open bodies of water,

hazardous liquids, or where flammable gases exist. These

fluids and gases may be present in containment areas.

Tank or wetwell must be vented per local codes.

Only pumps specifically Listed for Class 1, Division 1

are allowable in hazardous liquids and where flammable

gases may exist. See specific pump catalog bulletins or

pump nameplate for all agency Listings.

Disconnect and lockout electrical power

before installing or servicing any electrical

equipment. Many pumps are equipped with automatic

thermal overload protection which may allow an over-

heated pump to restart unexpectedly.

Do not use pump flammalde or explo-

sive liquids. Pump is for water only.

PERFORMANCE

PRE-INSTALLATION CHECKS

Open all cartons and inspect for shipping damage.

Report any damage to your supplier or shipping carrier

immediately.

Important: Always verify that the pump nameplate

Amps, Voltage, Phase and HP ratings match your control

panel and power supply.

This pump is oil-filled. If there are any signs of oil leak-

age or if the unit has been stored for an extended period

check the oil level in the motor dome and the seal hous-

ing, if so equipped.

Check the motor cover oil level through the pipe plug on

top of the unit. The motor chamber oil should just cover

the motor. Do not overfill, leave room for expansion!

WARNING

WARNING

WARNING

WARNING

MODELS

Order

Number

HP Phase Volts RPM Impeller

Dia. (In.)

Max.

Amps LRA

KVA

Code

Full Load

Motor Eff.

Resistance

Wt.

(Lbs.)

Cord

Length

Start Line-Line

WEHT0311M

0.33

1

115

1750

5.38

12.0

31.1

J

55

9.3

1.4

56

20'

WEHT0318M

208

7.3

19.5

K

51

9.1

4.2

WEHT0312M

230

6.1

16.5

J

54

11.7

5.6

*Add P1 to the end of the order number to include an ultra hi-temp float switch in the purchase.

Replacement part numbers for float: A2HT31 – 115V and A2HT32 – 208 and 230V (20' cord length).