Installation, Preinstallation, Pump location guidelines – Bell & Gossett P2000452 Series 580 User Manual

Page 13

Installation

Preinstallation

Precautions

WARNING:

• When installing in a potentially explosive environment, make sure that the motor is properly certified.

• You must earth (ground) all electrical equipment. This applies to the pump equipment, the driver, and

any monitoring equipment. Test the earth (ground) lead to verify that it is connected correctly.

• Motors without built-in protection must be provided with contactors and thermal overload protection

for single-phase motors, or starters with heaters for three-phase motors. (See the nameplate on the

drive unit to select properly-sized overloads.)

NOTICE: Supervision by an authorized representative is recommended to ensure proper installation.

Failure to do so may result in equipment damage or decreased performance.

Evaluate the installation in order to determine that the Net Positive Suction Head Available (NPSH

A

)

meets or exceeds the Net Positive Suction Head Required (NPSH

R

), as stated by the pump performance

curve.

Pump location guidelines

WARNING:

Assembled units and their components are heavy. Failure to properly lift and support this equipment can

result in serious physical injury and/or equipment damage. Lift equipment only at the specifically identified

lifting points. Lifting devices such as eyebolts, slings, and spreaders must be rated, selected, and used for

the entire load being lifted.

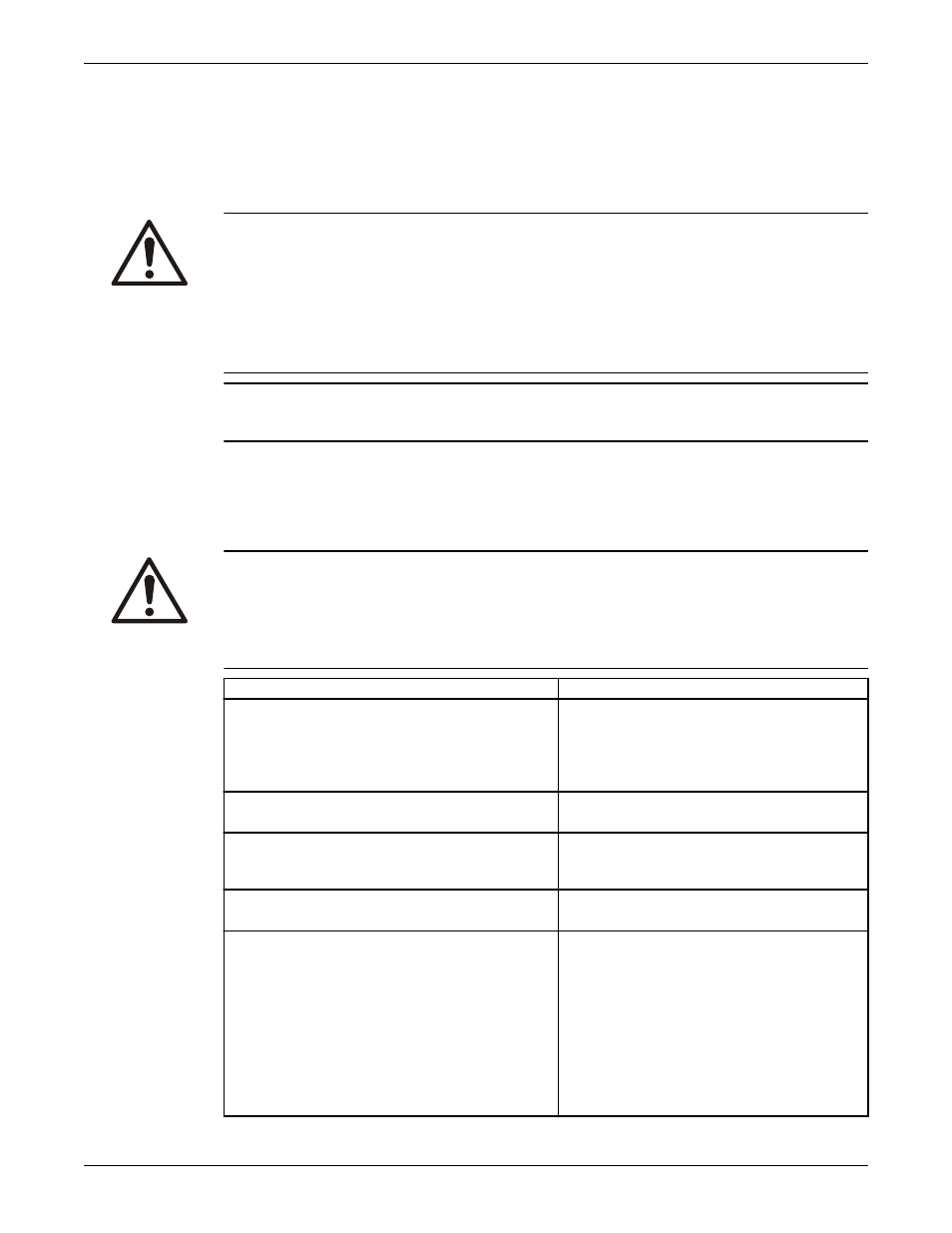

Guideline

Explanation/comment

Keep the pump as close to the liquid source as

practically possible.

If the pump is not on a closed system, locate the

pump so that the fewest number of bends or elbows

in the suction pipe are needed.

This minimizes the friction loss and keeps the

suction piping as short as possible.

Make sure that the space around the pump is

sufficient.

This facilitates ventilation, inspection,

maintenance, and service.

If you require lifting equipment such as a hoist or

tackle, make sure that there is enough space above the

pump.

This makes it easier to properly use the lifting

equipment and safely remove and relocate the

components to a safe location.

Protect the unit from weather and water damage due

to rain, flooding, and freezing temperatures.

This is applicable if nothing else is specified.

Do not install and operate the equipment in closed

systems unless the system is constructed with

properly-sized safety devices and control devices.

Acceptable devices:

• Pressure relief valves

• Compression tanks

• Pressure controls

• Temperature controls

• Flow controls

If the system does not include these devices,

consult the engineer or architect in charge before

you operate the pump.

Installation

Series 580 Installation, Operation, and Maintenance Manual

11