Pump operation guidelines – Xylem IM194 R02 GRINDER PUMPS 1 AND 3 11?4 DISCHARGE User Manual

Page 9

9

ENGINEERING DATA

PUMP OPERATION GUIDELINES

ENGINEERING DATA

Engineering data for specific models may be found in your catalog and on our website (address is on the cover).

Minimum Submergence

Continuous

Duty

Fully Submerged

Intermittent

Duty

6" Below Top of Motor

Maximum Fluid Temperature

Continuous

Operation

104º F 40º C

Intermittent

Operation

140º F 60º C

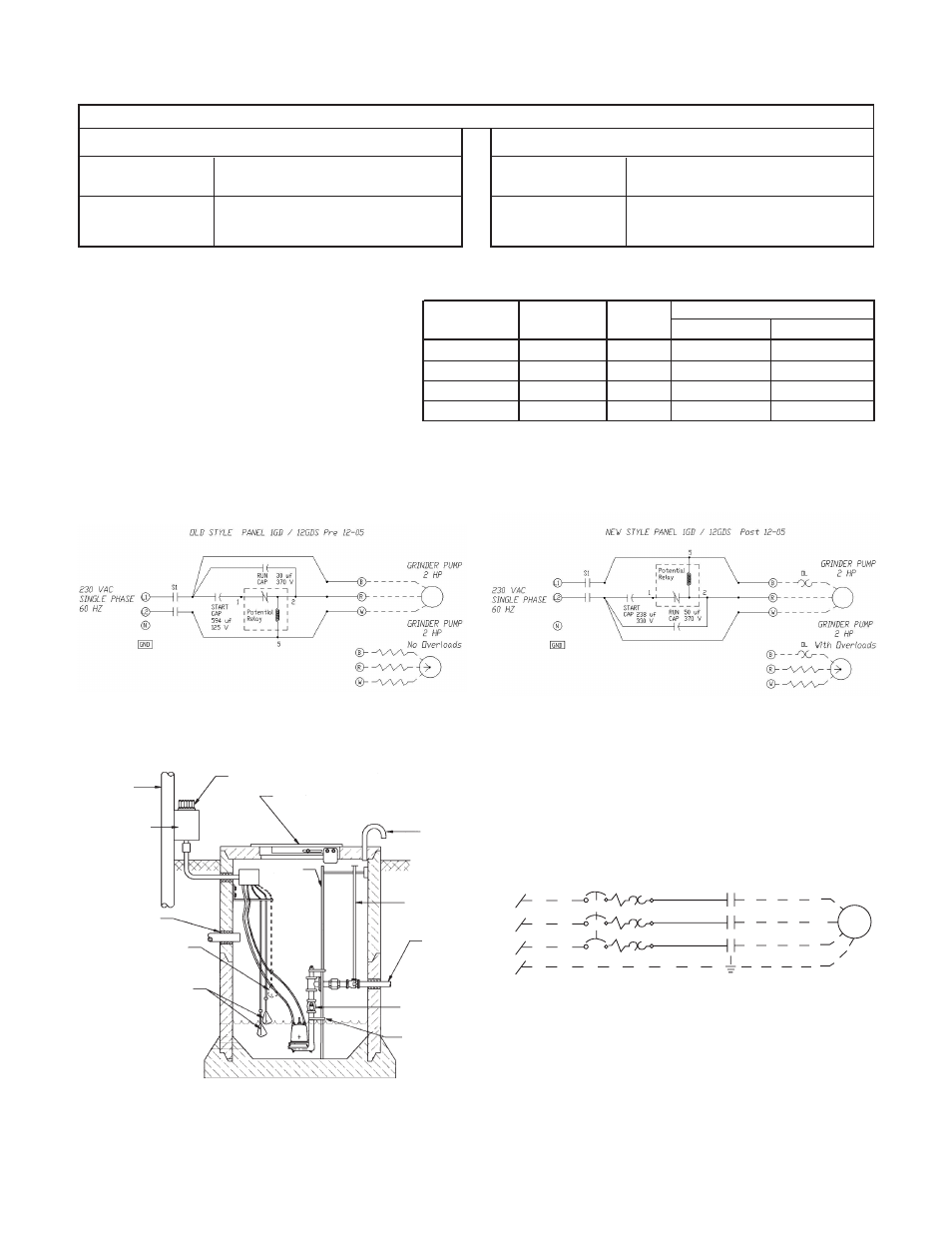

Fig. 2

L1

L2

L3

GRD

S1

Red

Black

White

Green

PUMP

Typical Three Phase Connection Diagram

TYPICAL PLUMBING AND INSTALLATION

TYPICAL PLUMBING AND INSTALLATION

SERVICE

POLE

CONTROL

PANEL

INLET GROMMET

FLOAT SWITCH

HIGH LEVEL ALARM

(OPTIONAL)

FLOAT SWITCH

ALARM LIGHT

HINGED ACCESS DOOR

VALVE

OPERATING

ROD

CHECK VALVE

LOWER

PUMP GUIDE

GUIDE

RAIL

DISCHARGE

VENT

Fig. 1

Effective with December 2005 (M05) Date Codes -

Single-Phase 1GD Pumps Contain a Built-in,

Auto Reset Overload.

Important Control Panel Requirements and Notes:

1) See panel bulletin BCP5 for other available options.

2) These pumps require a magnetic contactor, start and run capacitors

and a starting relay in the control panel.

3) CP-1GDB Capacitor packs with starting relays are available on

product bulletin BCPCAP. They are for certified panel shops to “build” into a custom panel. Field installing capacitor packs into a S10020 or D10020 will negate

the UL listing on that panel and is therefore not permissable.

Pump

Pump Seal Voltage Recommended Control Panel

Order No.

Fail Circuit / Phase

Simplex

Duplex

1GD51G1A_

NO

230 / 1

S1GD2

D1GD2

1GD51G8A_

NO

208 / 1

S1GD2

D1GD2

1GD51G1A_S

YES

230 / 1

S1GD2H

D1GD2J

1GD51G8A_S

YES

208 / 1

S1GD2H

D1GD2J

PANEL CAPACITOR WIRING DIAGRAMS

PANEL CAPACITOR WIRING DIAGRAMS

RECOMMENDED 1Ø CONTROL PANELS

RECOMMENDED 1Ø CONTROL PANELS