Xylem 2000 Series Frame Mounted Pumps AC8652 REV.C User Manual

Page 10

FIG

4.

to the

o same depth at 90°

um and maximum

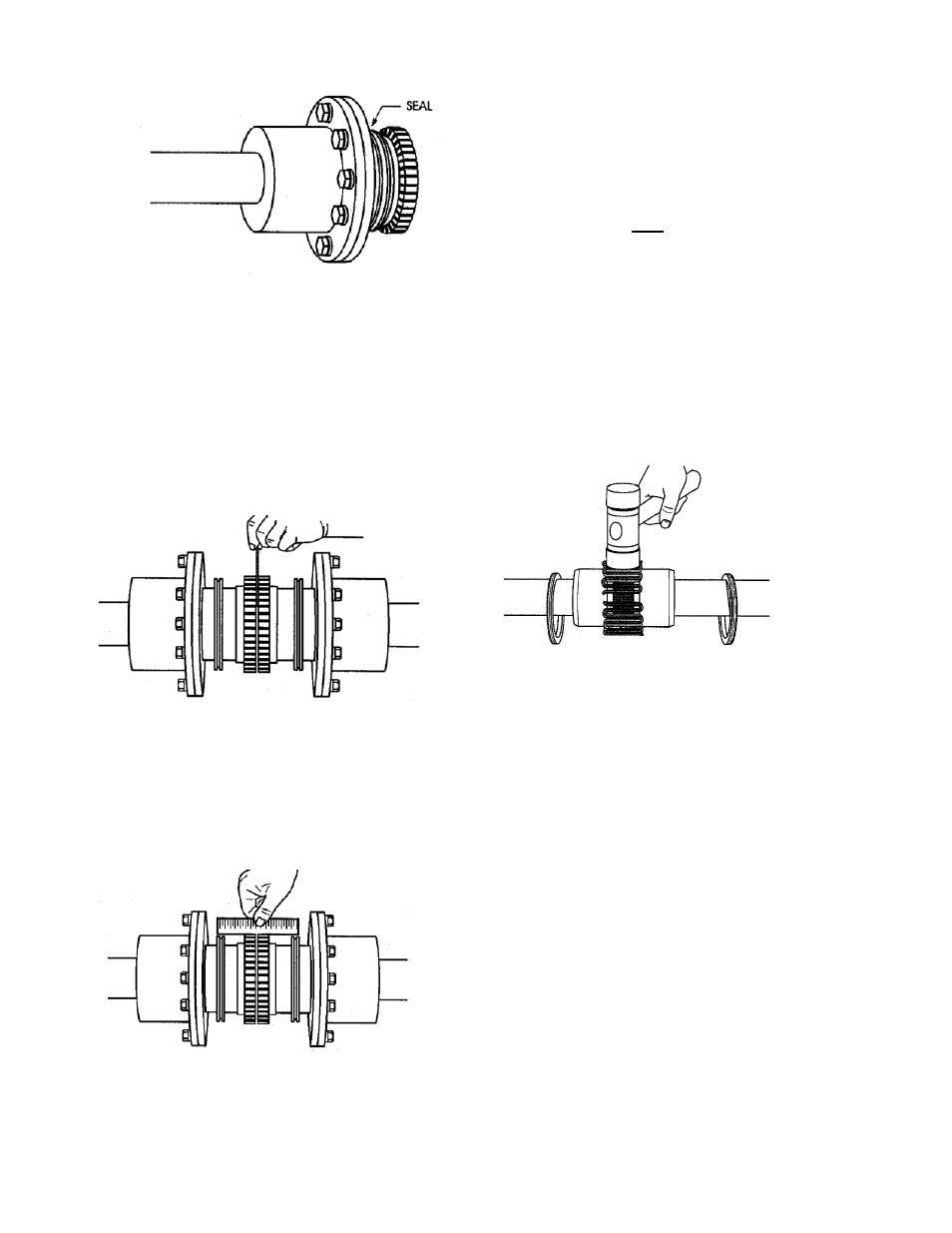

. 5D – SHAFT HUB, SEAL, & SPACER HUB

ASSEMBLY

Use a spacer bar equal in thickness

gap specified in Fig. 5J. Insert bar, as

shown below, t

intervals and measure clearance between

bar and hub face with feeler gauges. The

difference in minim

measurements must not exceed the

ANGULAR installation limits shown in

Fig. 5J.

FIG. 5E– USING SPACER BAR

5. Align so that a straight edge rest

the limits shown in Fig. 5J on both hu

shown below and also at 90° intervals.

Check with feelers. The clearance must

not exceed the PARALLEL OFFSET

installation limits specified in Fig. 5J.

s within

bs as

FIG. 5F – USING STRAIGHT

6. If adjustment is needed, loosen the motor

bolts and add (or remove) equal amounts

r each motor foot, to align

of shims unde

the height. To correct side misalignment,

strike the side of the motor foot with a

mallet. Tighten the motor bolts and check

again. If a correction is made, re-check

alignment in all directions. Repeat this

ling

wo or

nts, install them so that all cut

process until the desired result is

obtained.

7. Pack gap and grooves with coup

vendor supplied grease before inserting

grid. When grids are furnished in t

more segme

ends extend in the same direction as

shown below. This will ensure correct grid

contact with non-rotating pin in cover

halves. Spread the grid slightly to pass

over the coupling teeth and seat with a

soft mallet.

FIG. 5G – SEATING THE GRID

EDGE

10