Zero calibration – Analytical Industries GPR-1800 IS ATEX Trace PPM Oxygen Transmitter User Manual

Page 25

Advanced Instruments, Inc

25

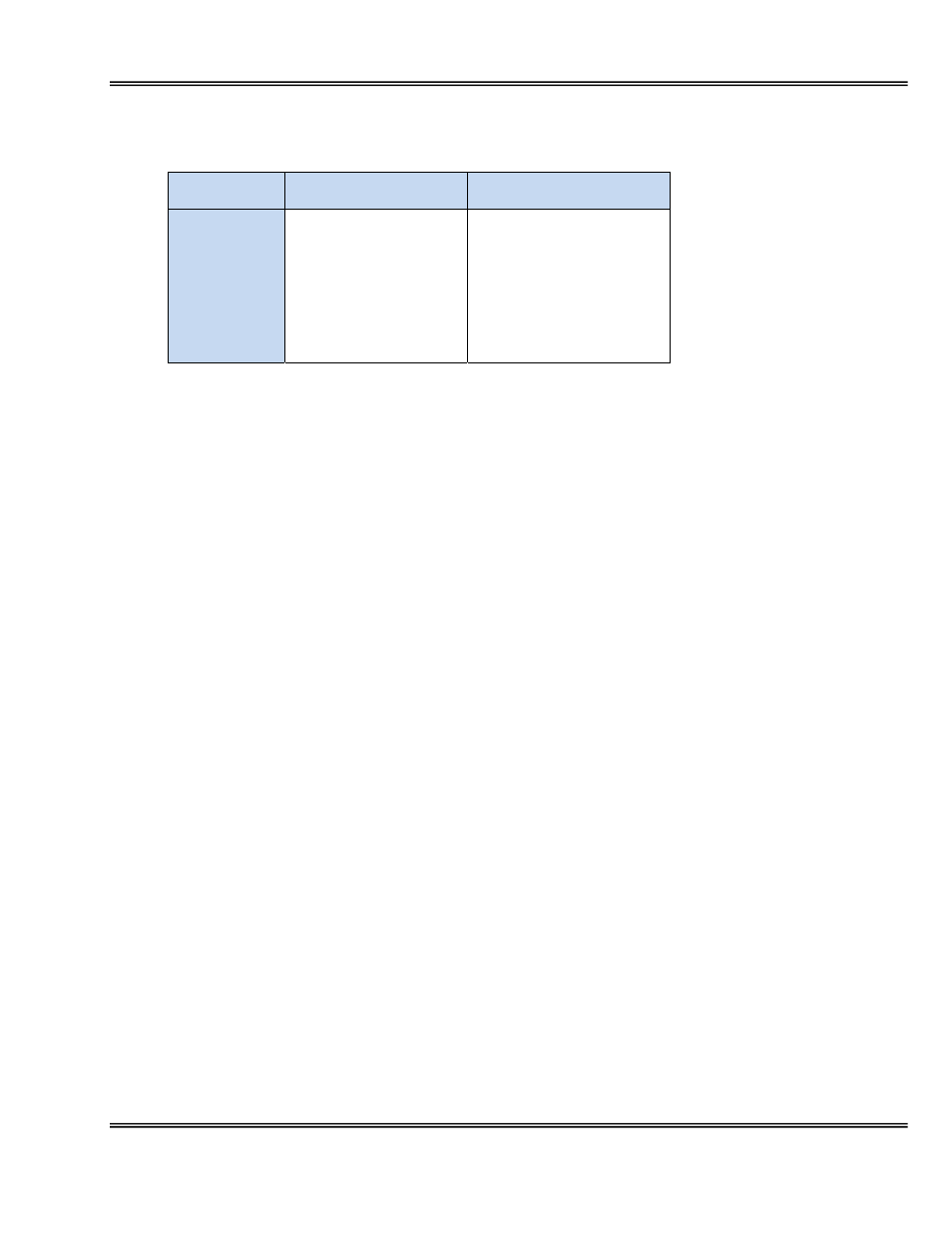

exposure to high O2 concentrations or air is significantly different if a sensor is being installed than if the

sensor had been in-service at low oxygen levels for more than 1 week.

Sensor

Calibration at

Install

In-service

Calibration

PPM

Fuel

Cell

Air to .1% < 1

min

Air to 100 PPM <

5 min

Air to < 10PPM <

60 min

Similar

Less than 45 min

The above times assume the introduction of a zero gas (low level of oxygen in nitrogen) after span

calibration.

For optimum accuracy, the O2 concentration of a span gas should be approximate 50-90% of the full scale

range of analysis or one range above the analysis range, e.g. 20.9% O2 on the 0-25% range. Conversely, if

the recommended span gas is not available and air calibration is not an option, a span gas of the same full

scale range and near the anticipated analysis level (approximately 30-50% of full scale) is acceptable with

the understanding that the accuracy will suffer slightly.

Use of span gas near 30% of the full scale range of measurements, at the higher end of the range has the

effect of “expanding the error” as illustrated by Graph A in Example 1 in the Accuracy section above.

Prematurely initiating the SPAN CALIBRATION function (before the analyzer reading has stabilized) can

result in erroneous readings as follows:

When purging an analyzer to lower ranges and calibrating with a span gas: If the oxygen reading reaches

less than 2% of the intended calibration range, enter the value of the span gas. If the oxygen reading is

greater than 2% of the calibration range, add the O2 reading to the value of the span gas (the impact of the

offset on accuracy is minor but the addition allows the oxygen sensor to continue to purge down and avoid

negative readings after calibration.

When installing a new oxygen sensor and calibrating with air, allow 2-3 minutes for the sensor to equilibrate

in ambient air from storage packaging. Failure to do so can introduce error in calibration.

Zero Calibration

Typical offset from a PPM analyzer is less than 0.5 PPM. Therefore, for most applications, a Zero calibration

is not required. However, ZERO calibration feature has been provided to allow the user to precisely measure

oxygen concentration at the very low levels (less than 0.5 PPM). As described below, accomplishing either

objective places a degree of responsibility on the user.

Determining the true offset requires the user to wait (see Online Recovery Time section) until the analyzer

reading is no longer trending downward (best evidenced by a constant horizontal trend on an external

recording device.

The zero offset adjustments is limited to 50% of the most sensitive range of the analyzer. At factory,

analyzer is QC tested to confirm that the maximum offset is less than 50% of the most sensitive range

available. Should you observe a zero offset more than 50% of the lowest range, check sample system for

any possible leaks, integrity of the zero gas and assure that the analyzer has been given enough time to

stabilize on zero gas before initiating the ZERO CALIBRATION.

Caution: If adequate time is not allowed for the analyzer to establish the true baseline and a ZERO

calibration is performed, the analyzer will in all probability display a negative reading in the sample mode

after a certain period of time. If a negative reading is seen, perform ZERO calibration again.