Procom MU 9-xp4r-... User Manual

Page 2

SPECIFICATIONS

ELECTRICAL

MODEL

MU 9-XP4R/...

ANTENNA TYPE

End-fed ½ λ mobile whip antenna

FREQUENCY

450 MHz–band covered by three

models

IMPEDANCE

Nom. 50 Ω

POLARIZATION

Vertical

GAIN

2 dB (acc. to EIA RS-329-1)

BANDWIDTH

≥ 15 MHz @ SWR ≤ 1.5

≥ 30 MHz @ SWR ≤ 2.0

SWR

≤ 1.3 @ f. res.

MAX. POWER

40 W

MECHANICAL

MATERIALS

Whip:

Black-chromed, conical stainless steel

Black-chromed brass

Mount:

Black-chromed brass

Weather- and shockproof plastics

Surface treated steel

RECOMMENDED INSTALLATION

TORQUE

Max. 3 Nm

CABLE

4 m cable terminated with FME-

connector.

Other cable lengths and connector

types on request

(see ordering designations)

COLOUR

Black

HEIGHT

Approx. 40 cm (see cutting diagram)

WEIGHT

Approx. 210 g

MOUNTING

From outside: 21 mm dia. hole

From inside: 14 mm dia. hole

ROOF THICKNESS

0.6 → 5.0 mm

INSTALLATION

This antenna is especially designed for installation on non-conducting

surfaces as e.g. glass fibre roofs, as can be found on some trucks, busses,

transport vans and trains.

The antenna is an end-fed, ½ λ-dipole concept which can be fed in such a

way that the antenna does not require a “groundplane” as required by the

standard ¼ λ, ⅝ λ or colinear mobile whips.

It is useful to note that this antenna type can be used anywhere, where the

ground-plane is poor or completely missing, as e.g.: side-mounted on a

clamp as a pager antenna on a wall, or mounted at the very edge of a

ground-plane without the loss induced by a tilted radiation pattern.

The antenna must be mounted on a horizontal surface. When cleaning the

vehicle in car-washing machines, the whip is easily dismounted using a

spanner, size 9 mm. The whip is refitted again by screwing it onto the M6

thread stud on the mount and tightening it lightly with the spanner.

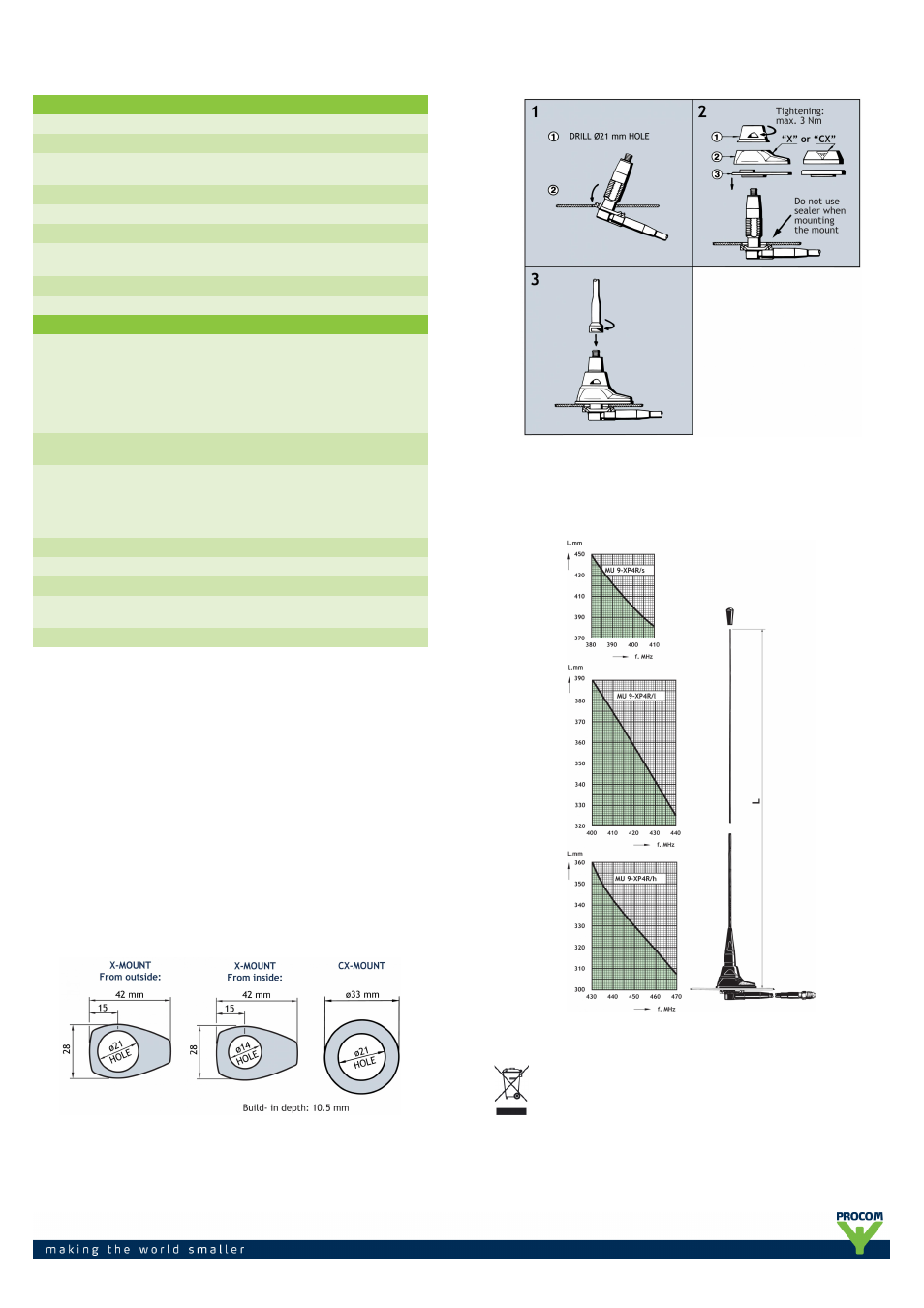

1. INSTALLATION DIMENSIONS

2. INSTALLATION STEPS (From outside)

Do not use sealer on rubber gasket or other places.

3. TUNING

The antenna should always be tuned using an SWR-indicating device. The

cutting diagrams below serve as a guide for this procedure.

PROCOM A/S reserve the right to amend specifications

without prior notice.

18/02/13