2 en_ 03585t3r-installation manual.pdf, Adjustment – Factory Direct Hardware Toto TEU1LN12#CP User Manual

Page 2

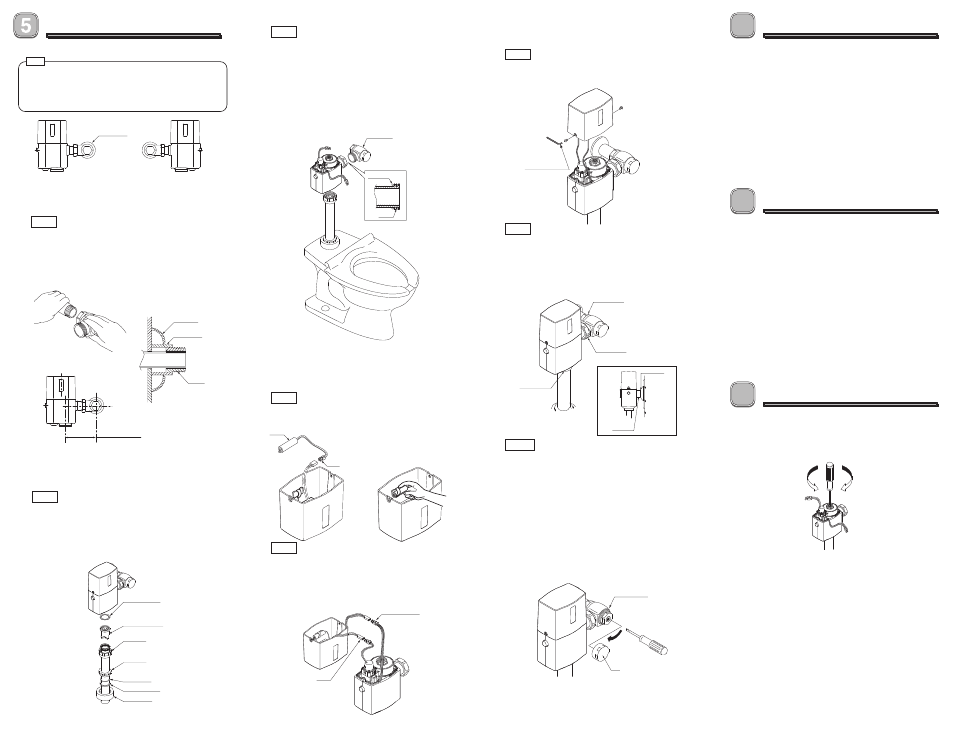

Installation Procedure

Test Run

Note to the installer

7

6

Adjustment

Step 1 (For New Installation)

Escutcheon

White

White(Toilet type)

Yellow(Urinal type)

Yellow

Battery

Covering tube

Control Stop

Adapter

Min.4-1/4"(107mm)

Max.5-1/4"(133mm)

Install the control stop using a proper size escutcheon and

1. For left water supply, attach the sensor top cover in the

opposite direction so that the sensor will be at the front.

2. For retrofit installation, remove the old flush valve after

shutting off the control stop.

sweat solder adapter kit if applicable. Thread sealing

compounds should be used on male NPT threads only. The

distance from center of the control stop to center of the flush

valve should fall within 4-1/4" to 5-1/4"(107mm to 133mm).

Step 2

Determine the length of vacuum breaker tube to join the

flush valve and fixture spud. Cut the vacuum breaker tube,

if required, to the proper length. Assemble the spud nut

assembly to the fixture spud. Hand tighten spud nut to

fixture.

For sweat solder

Right Water Supply

Left Water Supply

Step 5

Connect the connectors of solenoid valve

and generator with those of controller.

Step 3

Prior to inserting the flush valve tailpiece into the control stop,

be certain that the O-ring is in the groove at the end of the

tailpiece, the locking nut and the snap ring are located as

shown. Connect the flush valve with the control stop and the

vacuum breaker tube. Care should be taken not to damage the

O-ring when inserting the tailpiece into the control stop.

If lubrication is needed, wetting the O-ring with water will be

sufficient. Align the flush valve and securely tighten fixture spud

nut, vacuum breaker tube nut and locking nut with a wrench.

Step 4

Connect the connector of the battery with that of the controller

and set it at the proper position as shown below.

Step 6

Fasten the sensor top cover on body cover with the

supplied screws (use supplied allen wrench).

Step 7

Before the supply water is turned on, be sure all water

leaks are eliminated by tightening all the pipe connections.

If for any reason it becomes necessary to remove the

control stop , be certain the water is shut off at the main

supply valve.

Pipe connection

Pipe connection

Pipe connection

Escutcheon

Joint tube

Cap

Step 8

The flush valves are preset for fixture volume as marked

on the valve carton. The valve does not require adjustment

for variation in water pressure within its operating range.

To set the flush valve for proper operation, open the

control stop completely by using the adjusting screw and

flush the flush valve several times. Gradually adjust the

control stop closed, using the adjusting screw, so that the

rate of water flow into the fixture is not excessive, yet is

sufficient to adequately evacuate the waste. The cap for

the control stop should be placed after final adjustments

have been made. Tighten the cap firmly with a wrench.

1. Make sure the control stop is open.

2. Sit on the toilet seat. (for Toilet flush valve)

Stand within two feet from the front of the flush valve.

(for Urinal flush valve)

3. Stay there for 6 seconds or more and then leave the

toilet seat or the urinal. The valve will automatically flush.

4. Press the manual flushing button and make sure the

valve flushes properly and the sensor red light is on for

2 seconds.

5. Recheck all the pipe connections for water leaks. If the

flush valve is not operating properly following the test

run consult the Troubleshooting section of the Owner's

Manual.

After the flush valve unit has been installed correctly,

please explain to your customer how to use it and tell them

to observe the following instructions.

1. Do not put any object in front of the sensor window

which could obstruct the sensor, causing it to

malfunction.

2. For troubleshooting, consult the Owner's Manual.

If you lack the necessary skills required or have

difficulty following the directions for installation,

maintenance, repairs, troubleshooting or

adjustments, of the product, do not proceed without

help from a qualified person to assist you in

performing any of these functions.

1. Adjustment of the discharge quantity

(1) Remove the sensor top cover.

(2) Adjust the discharge quantity by rotating the screw

on the piston valve.

2. Adjustment of the flow rate

Adjust the flow rate by turning the screw of the control

stop.

Turn the screw to the right to decrease the flow rate and

turn it to the left to increase.

3. Adjustment of the detection range

The detection range of the infrared sensor does not

need to be adjusted because it has been factory-preset.

Printed in September, 2007

8

Friction Washer

Vacuum Breaker

Tube Nut

Spud Nut

Slip Gasket

Rubber Gasket

Escutcheon

To increase

To decrease

Control stop

Note

Control stop

Snap ring

O-ring

Supplied

Allen wrench