3B Scientific Relative Pressure Sensor, ±100 hPa User Manual

Page 6

2

•

Note the “positive” and “negative” labelling of

the hose connections - connect the hoses

correctly according to the effective direction of

the pressure.

•

During the experiment, check that no elastic

expansion of the hose is occurring – this can

cause the pressure reading to be lower than

the correct value.

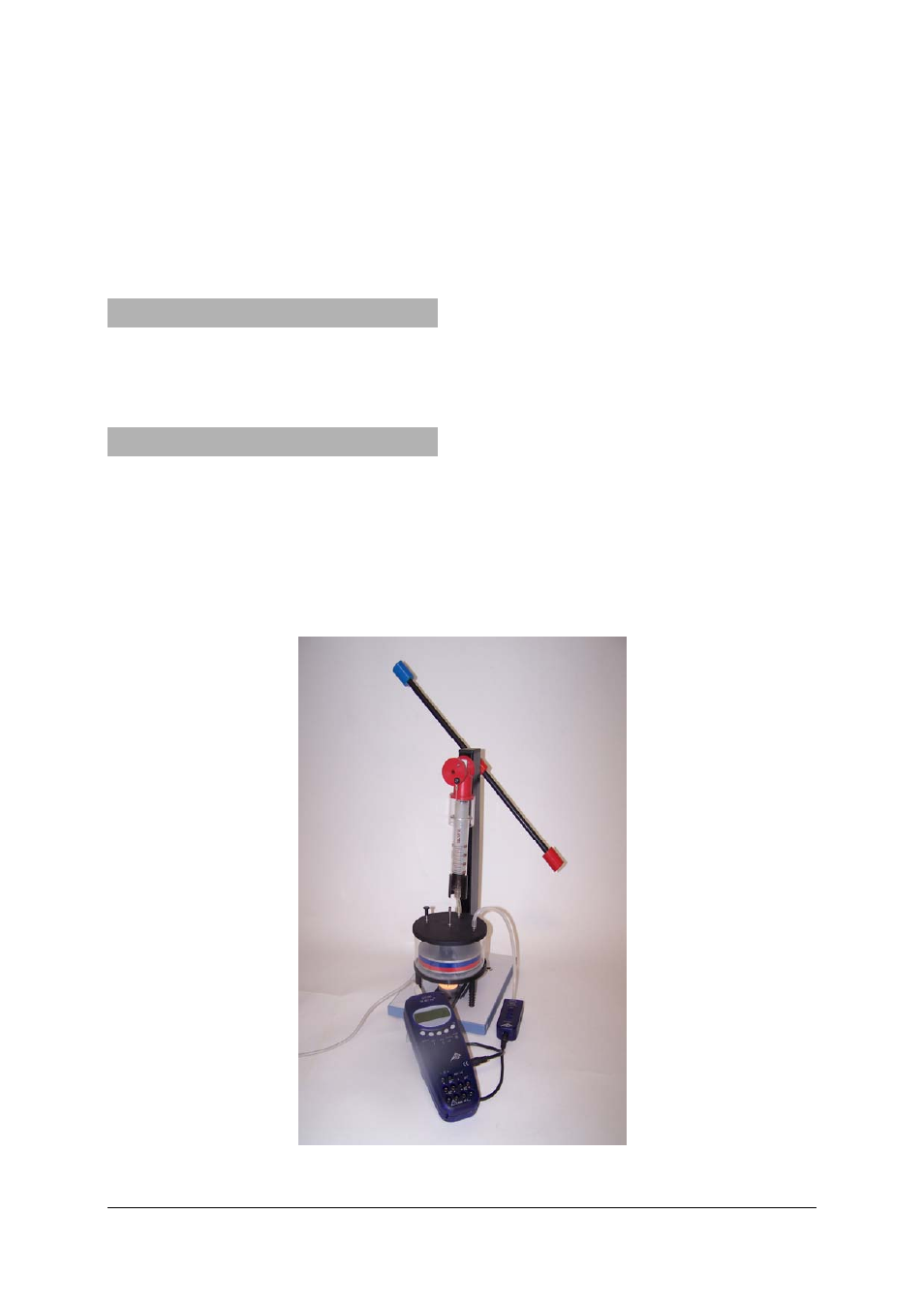

6. Application

Measurement of the pressure difference in the

Stirling engine U8440480, and analysis of the data

using 3B NETlab

TM

.

7. Sample experiment

Recording operating pressures in Stirling engine

U8440480 while it is in motion

Apparatus required:

1 3B NETlog

TM

unit U11300

1 3B NETlab

TM

program

U11310

1 Relative pressure sensor, ±100 hPa

U11321

1 Wilke-type Stirling engine

U8440480

•

Set up the experiment as shown in fig. 1.

•

Connect the relative pressure sensor to the 3B

NETlog

TM

unit and wait for the sensor to be

detected.

•

Use a suitable length of silicone hose to make

the pressure connection between the “positive”

hose connection of the sensor box and one of

the two hose connections of the Stirling

engine. The two hose connections of the

engine are identical in their function.

•

Allow the engine to heat up and, after a few

minutes, set it running.

•

Open the application program (template) for

the experiment with the ±100 hPa relative

pressure sensor on the 3B NETlab

TM

unit.

•

Measure the pressures.

•

Evaluate the curve resulting from the

measurements (fig. 2).

Fig. 1 Experiment set-up for recording operating pressures in the

Wilke-type Stirling engine while in motion