Slowly open the regulating valve and let in the sf, Shut the regulating valve, Shut the flush valve. filling with test gas – 3B Scientific Critical Point Apparatus User Manual

Page 6: Flushing out air, Onto the gas connec- tion fittings

6

the pipe (more precisely, on the ratio of the pipe

length to the volume of the measuring cell). In the

process, care should be taken that the quantity of the

greenhouse gas SF

6

released in the environment is

reduced to a minimum.

Connecting a fixed pipe:

0 0

1 9

1 8

1 7

1 6

1 5

10

0

20

30

40

50mm

a

b

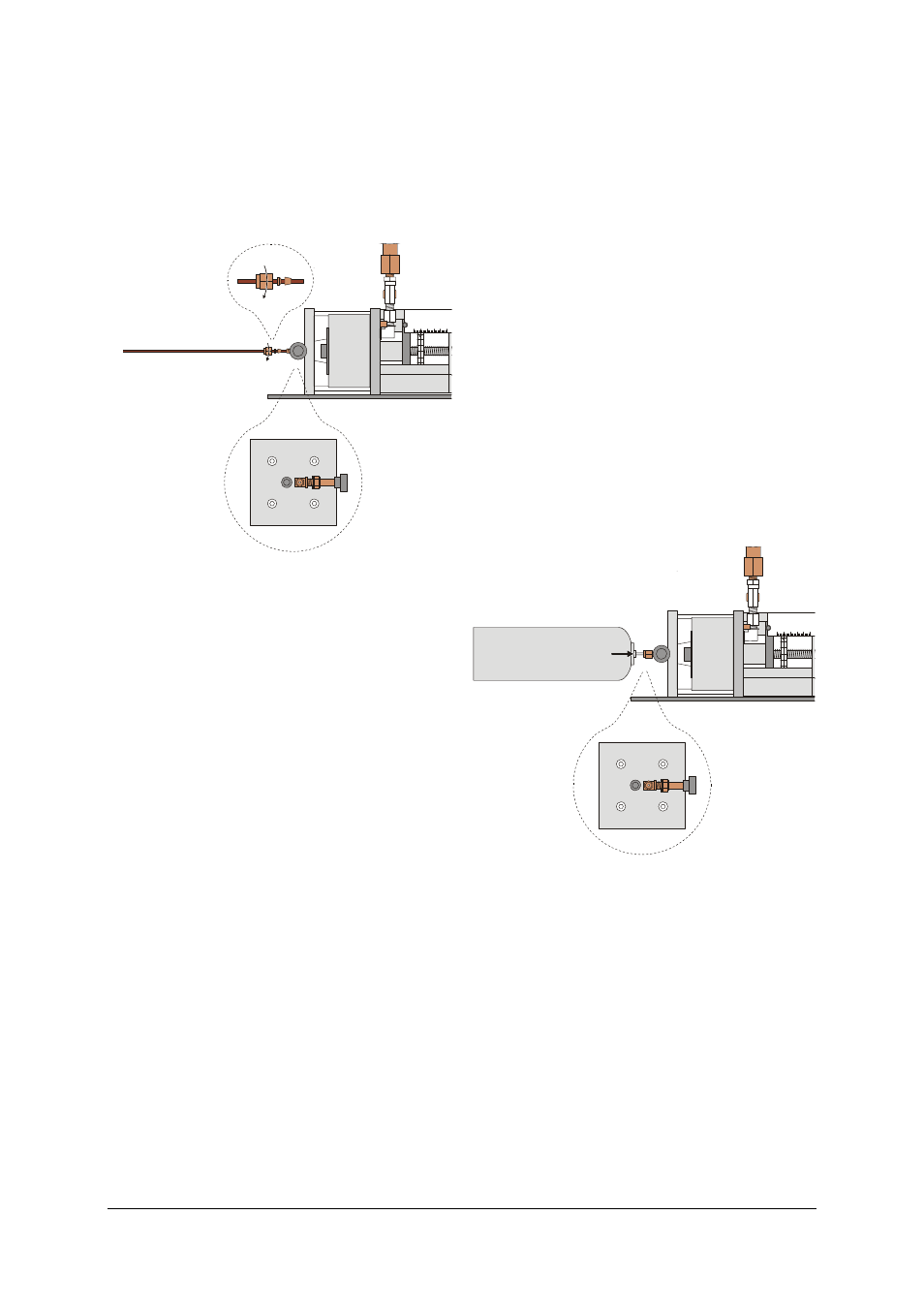

Fig. 3: Connecting a fixed pipe

(a) flush valve, (b) regulating valve

•

If necessary, pull out the protection for the gas

connection and loosen the valve nut (11 mm) to

remove the 1/8" gas connection fittings.

•

Connect the pipe (if necessary with adapters) to

the gas fitting.

•

Beginning with the valve nut, slide the supplied

screw joints onto the tubing. (See Fig. 3: follow

the sequence and alignment specified along with

the cable binder)

•

Insert the pipe into the regulating valve and

tighten the valve nut till the point is reached

where it is no longer possible to move the pipe

any further using only your fingers.

•

Hold the regulating valve still with an open-end

spanner (13 mm) and tighten the valve nut by a

further 270°.

Now, the connection is gas-tight. When loosening the

valve nut afterwards, the regulating valve also needs

to be held still with a spanner.

Flushing out air:

•

Use the handwheel to set the piston position to

10 mm.

•

Slowly open the regulating valve and let in the SF

6

till a pressure of approx. 10 bar has been at-

tained.

•

Shut the regulating valve.

•

Open the flush valve slightly till the pressure has

dropped to almost 0 bar.

•

Shut the flush valve.

Filling with test gas:

•

After at least four flush cycles, open the regulat-

ing valve till the pressure attained is once again

10 bar.

•

Shut the regulating valve.

•

Turn the handwheel in the reverse direction till

the piston reaches a position of say 46 mm.

•

Slowly open the regulating valve and shut it again

when a pressure of 10 bar has been attained.

7.3 Filling with gas from a MINICAN®:

Additionally required:

1 MINICAN® gas container with SF

6

, e.g. from the

company Westfalen (www.westfalen-ag.de

If the equipment is used only occasionally, it is more

practical to draw the test gas from a MINICAN® gas

container. The gas connection of a MINICAN® con-

tainer is similar in design to a commercial spray can,

i.e. it opens when the MINICAN® container is pressed

directly onto the gas connection fittings.

Here too, filling begins with several rinsing cycles for

flushing out the air.

0 0

1 9

1 8

1 7

1 6

1 5

10

0

20

30

40

50mm

SF

6

a

b

Fig. 4: Filling with test gas from a MINICAN® gas container

(a) flush valve, (b) regulating valve

Flushing out air:

•

If necessary, pull off the protection for the gas

connection.

•

Use the handwheel to set the piston position to

10 mm.

•

After removing the protective cap, position the

MINICAN® container with SF

6

onto the gas connec-

tion fittings.

•

Press the MINICAN® container onto the gas con-

nection fittings, slowly open regulating valve (b)

and let in SF

6

till a pressure of approx. 10 bar has

been attained.

•

Shut the regulating valve.