3B Scientific Critical Point Apparatus User Manual

Page 4

4

the corresponding pressures p

0

and p

1

of the trapped

air, we get:

1

1

0

0

s

p

s

p

⋅

=

⋅

(2)

Substituting

s

s

s

Δ

+

=

1

0

and rearranging gives:

s

p

p

p

s

Δ

⋅

−

=

0

1

0

1

(3)

Rough calibration of scales:

•

Open the regulating valve wide.

•

Loosen the grub screw for the vernier scale by

half a turn (it is now possible to turn the scale

easily on the threaded axle without moving the

handwheel, although a counterpressure acts

against this independent movement).

•

Wind the handwheel out till you detect a notice-

able resistance.

•

Without turning the handwheel, turn the vernier

scale on the threaded axle till the 0.0 mark is on

the top and the fixed scale shows approx. 48 mm.

•

Loosen the knurled screws of the fixed scale and

shift the scale to the side till the 48-mm bar is ex-

actly above the centre line of the vernier scale

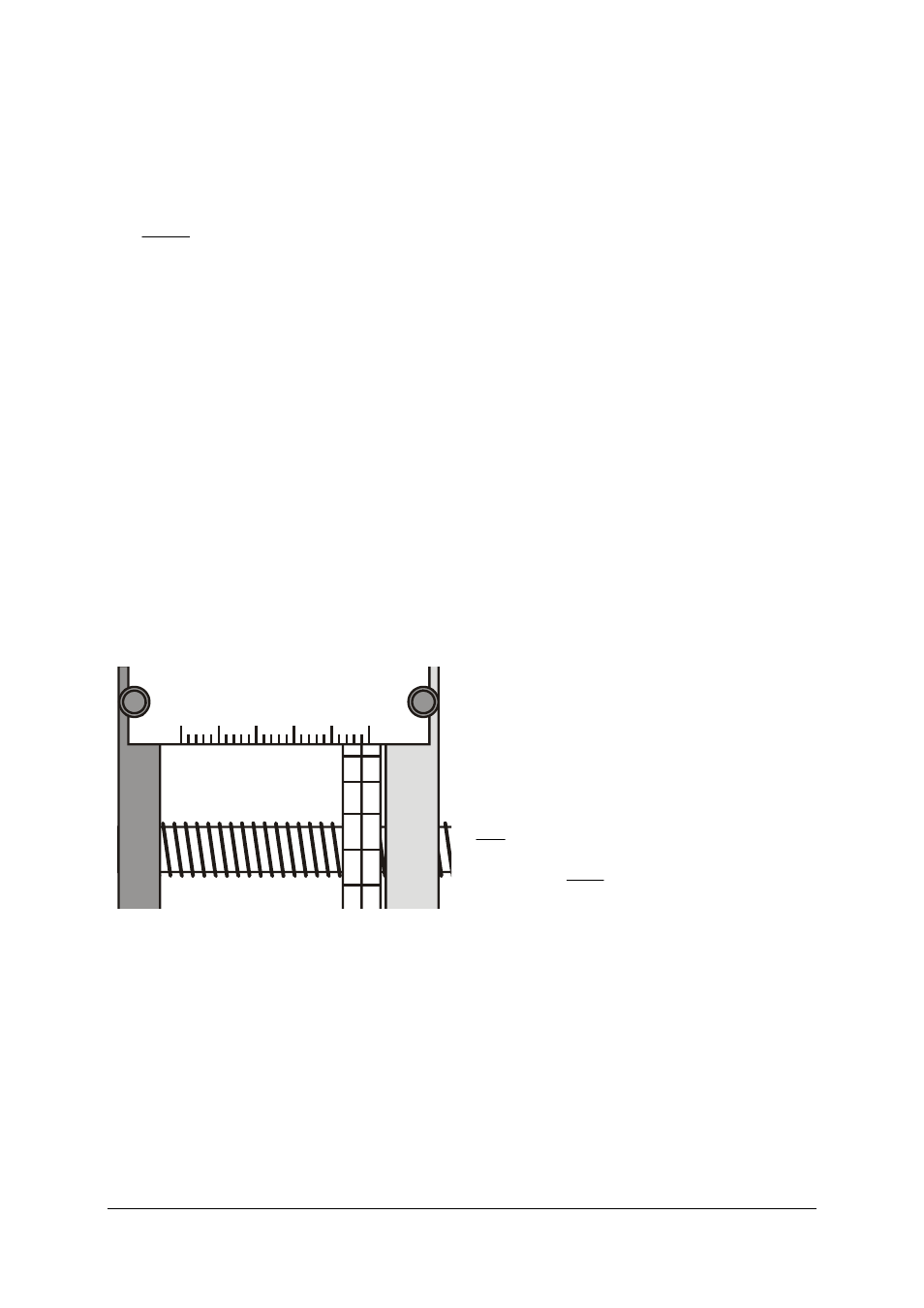

(see Fig. 2).

•

Tighten the knurled screws again. In doing so,

make sure that the fixed scale does not press

against the vernier scale.

0 0

1 9

1 8

1 7

1 6

1 5

10

0

20

30

40

50mm

Fig. 2: Piston position reading at 48.0 mm

Zero correction:

•

Shut the regulating valve (the pressure in the

measuring cell now corresponds to the ambient

pressure p

0

= 1 bar. To within the accuracy of the

measurement, the manometer should display an

excess pressure of 0 bar).

•

Wind the handwheel in till an excess pressure of

15

bar has been reached (absolute pressure

p

1

= 16 bar).

•

Read the piston position s

1

and calculate the

displacement

Δs = s

0

– s

1

.

•

Calculate the zero corrected piston position s

1, corr

using Equation 3.

•

Adjust the vernier scale to the corrected value

and, if necessary, move the scale again.

•

If required, wind the handwheel out a little and

secure the vernier scale with the grub screw.

Measurement example:

p

0

= 1 bar, p

1

= 16 bar, p

1

– p

0

= 15 bar

s

0

= 48.0 mm, s

1

= 3.5 mm,

Δs = 44.5 mm

Therefore, s

1, corr

= 2.97 mm.

The vernier scale must therefore be adjusted so that

now only 2.97 mm are shown instead of 3.50 mm.

Note:

After calibrating the zero point, it is possible to obtain

qualitatively accurate measured values. With regard

to temperature T and pressure p, it is also possible to

obtain quantitatively accurate measurements of the

isotherms in range around to the critical point where

the two phases exist simultaneously. However, espe-

cially in the liquid phase, the measured isotherms are

rather too widely separated.

6.3 Detailed calibration:

The exact relation between the volume V

G

in the

measuring cell and the scale reading s is dependent

on the volume of oil in the oil chamber. The oil

chamber also expands marginally in proportion to the

pressure as a result of the spring in the manometer

tube. Additionally, when the temperature is in-

creased, the castor oil expands to a greater extent

than the rest of the equipment. This means that the

pressure rises at a slightly greater rate at higher tem-

peratures. All of these phenomena can be calculated

if appropriate calibration has been effected using air

as an ideal gas.

The ideal gas equation would thus be:

R

n

T

V

p

⋅

=

⋅

(4)

with

mol

K

J

314

8.

R

=

After taking the overpressure reading p

e

, the absolute

pressure can be calculated from:

p

= p

e

+ 1 bar

(6)

The absolute temperature is given by:

T

=

ϑ + ϑ

0

where

ϑ

0

= 273.15°C

(7)

The volume is given by:

s

A

V

⋅

=

G

(8)

where

2

cm

14

3,

A

=

and s is the “effective” piston

displacement.

From the measured displacement s

e

, it is possible to

calculate the effective piston displacement as follows: