3B Scientific Critical Point Apparatus User Manual

Page 5

5

ϑ

⋅

−

⋅

+

+

=

ϑ

C

p

C

s

s

s

p

e

0

(9)

By substituting in equation 4, we get:

(

)

0

0

0

=

⋅

−

ϑ

+

ϑ

⋅

ϑ

⋅

β

−

⋅

β

+

+

⋅

ϑ

R

n

A

p

s

s

p

p

e

(10)

If we take several readings at various temperatures

and pressures, we can calculate the term:

(

)

∑

=

ϑ

⎟⎟

⎠

⎞

⎜⎜

⎝

⎛

⋅

−

ϑ

+

ϑ

⋅

ϑ

⋅

β

−

⋅

β

+

+

⋅

=

n

p

R

n

A

p

s

s

p

Q

1

i

2

0

i

i

0

i

i

(11)

The free parameters s

0

,

β

P

,

β

ϑ

and n should be appro-

priately selected so that the value of Q is reduced to a

minimum.

Additionally required (see also chapter 8):

1 Compressor or bicycle pump and valve

1 Bath/circulating

thermostat

1008653/1008654

1 Dig. quick-response pocket thermometer 1002803

1 Type K NiCr-Ni immersion sensor, -65°C-550°C

1002804

2 Silicone tubes, 1 m

1002622

1 l Anti-freeze fluid with corrosion-inhibiting additive

for aluminium engines (e.g., Glysantin® G30 ma-

nufactured by BASF)

Conducting the calibration:

•

Connect the circulation thermostat as described

in chapter 8 and fill it with the water/anti-freeze

mixture.

•

Connect the plastic tube (3-mm internal diameter)

to the 1/8" gas connection fittings.

•

Open the regulating valve.

•

Wind the handwheel outwards, making the piston

move till it reaches say the 46.0 mm position.

•

Use a compressor or a bicycle pump to create an

excess air pressure of approx. 3-8 bar in the

measuring cell.

•

Shut the regulating valve.

•

To record measurements, vary the volume in the

measuring cell or the temperature of the thermo-

stat and wait till a stationary equilibrium has

been attained. Then take a pressure reading.

•

Use appropriate adjustment software to set the s

0

,

β

P

,

β

ϑ

and n parameters so that the quadratic

equation for the errors Q is reduced to a mini-

mum (see equation 11).

•

If you like, you can adjust the vernier scale

around s

0

so that this correction is not necessary.

With the set parameters, it is possible to calculate the

“effective” piston displacement s from the measured

displacement s

e

using Equation 9 and then to calcu-

late the calibrated measuring cell volume using Equa-

tion 8.

Sample measurements:

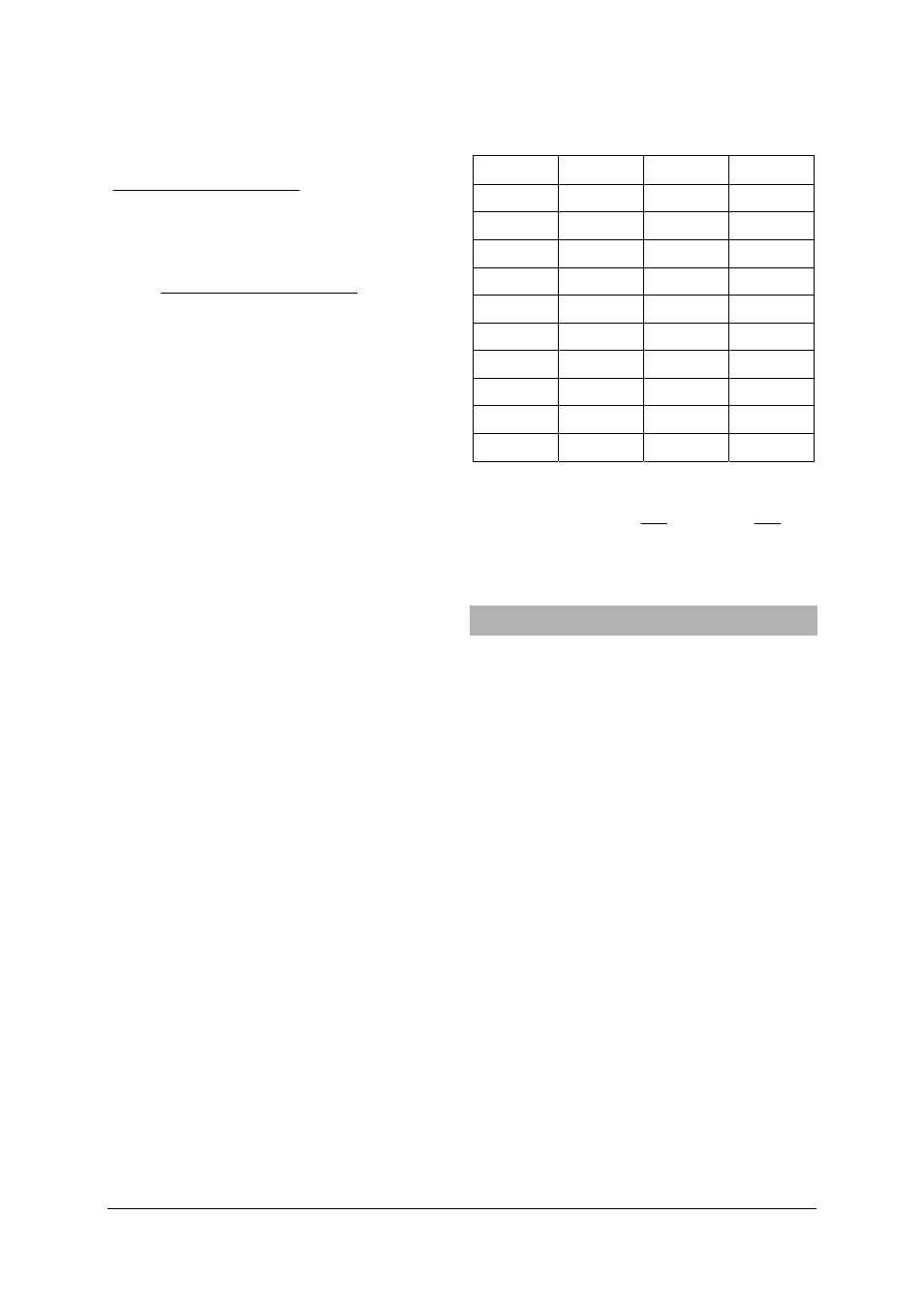

Table 1: Measured values for calibration

i s

e

/ mm

ϑ

p / bar

1 40.0

20.0°C

6.6

2 20.0

20.0°C

12.4

3 10.0

20.0°C

23.3

4 5.0

20.0°C

41.8

5 3.5

20.0°C

53.9

6 5.0

20.0°C

41.8

7 5.0

10.0°C

38.9

8 5.0

30.0°C

45.3

9 5.0

40.0°C

49.0

10 5.0

50.0°C

53.5

The following parameter values are obtained:

s

0

= 0.19 mm,

bar

mm

023

0

P

.

=

β

,

grd

mm

034

0.

=

β

ϑ

and

n = 0.00288 mol.

7. Filling with test gas

7.1 Handling of sulphur hexafluoride:

Sulphur hexafluoride (SF

6

) is a non-toxic gas and is

absolutely safe for humans. The MAC value for danger

of suffocation on account of oxygen deprivation is

1000 ppm. That is equivalent to 6 filled measuring

cells per 1 m

3

of air.

However, SF

6

is extremely harmful to the environment

and can give rise to a greenhouse effect 24,000 times

stronger than CO

2

. Therefore, do not allow large quan-

tities to be released into the environment.

7.2 Gas connection via fixed pipes:

Additionally required:

1 SF

6

gas cylinder with manufacturer’s/supplier’s rec-

ommended gas fittings/valves, e.g. SH ILB gas cylinder

and Y11 L215DLB180 regulating valve from Airgas

(www.airgas.com).

1 Pipes with outer diameter of 1/8" and, if necessary,

adapters, e.g. from Swagelok (www.swagelok.com).

1 open-end spanner (13 mm), 1 open-end spanner

(11 mm)

According to the principles of “good laboratory prac-

tice”, it is recommended to utilise a gas supply via

fixed pipes, especially if the equipment is regularly in

operation.

Filling begins with several flush cycles in which the air

is flushed out of the pipe. The number of cycles re-

quired to flush out the air depends on the length of