3B Scientific Heat Pump D (115 V, 60 Hz) User Manual

Page 4

4

7. Heat pump cycle

1

4

2

3

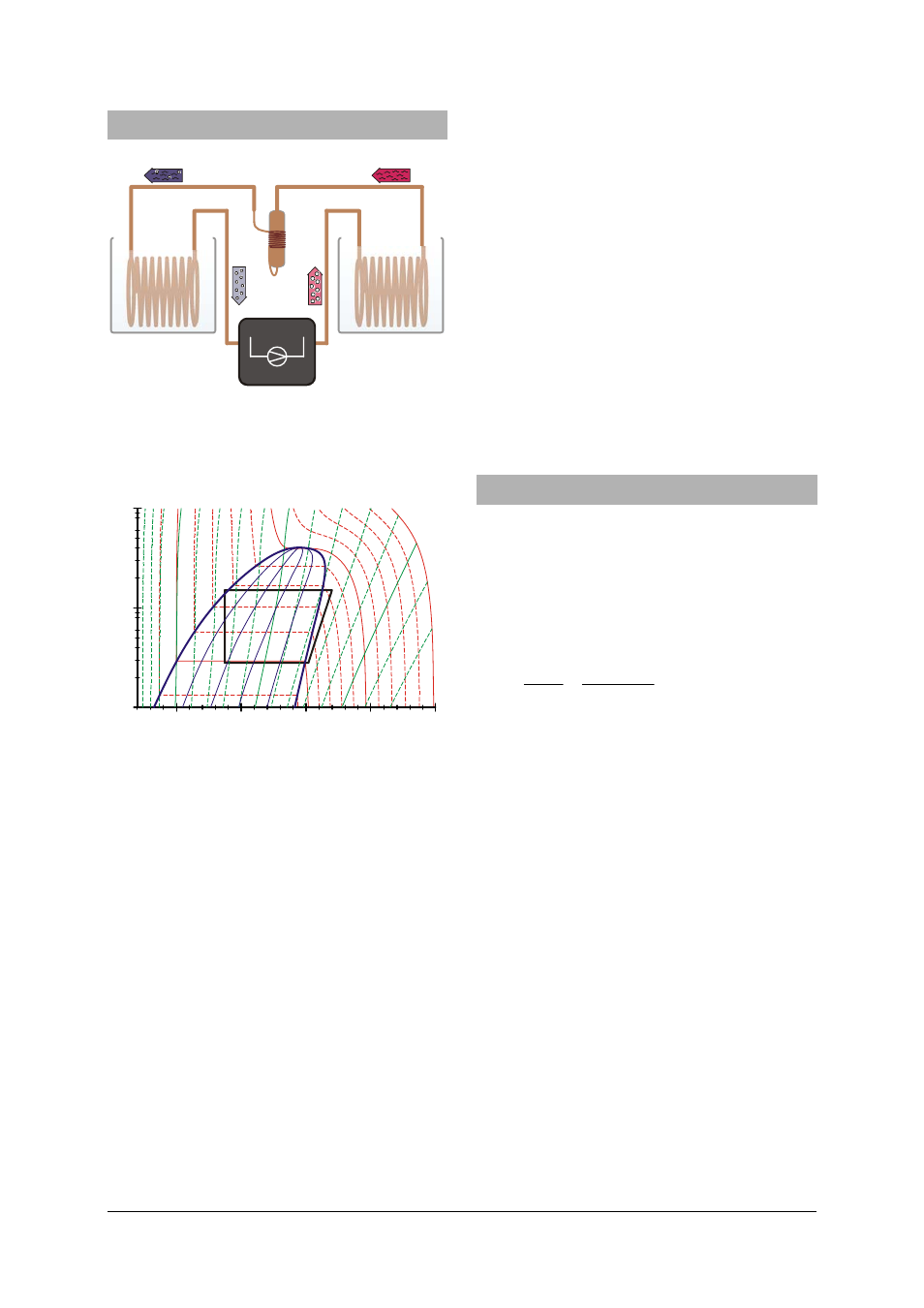

Fig. 4 Schematic diagram of the heat pump with

compressor (1→2), condenser (2→3), ex-

pansion valve (3→4) and evaporator (4→1)

1.

0

1.

5

S / kJ/kg K

T

2.

0

600

500

H / kJ/kg

p / mbar

400

300

1

2

3

4

200

0.1

1

10

200°C

100°C

0°C

Fig. 5 Mollier diagram of ideal heat cycle (see sec-

tion 7)

The idealised version of the heat pump cycle

involves four steps: compression (1→2), lique-

faction (2→3), controlled expansion (3→4) and

vaporisation (4→1):

Compression:

The gaseous refrigerant is sucked in by the com-

pressor without changing the entropy (s

1

= s

2

). It

is then compressed from pressure p

1

to p

2

which

causes excess heat to be generated. The tem-

perature rises from T

1

to T

2

. The mechanical work

done per unit mass is Δw = h

2

– h

1

.

Liquefaction:

The fluid cools sharply inside the condenser caus-

ing it to liquefy. The heat emitted by this process

(latent heat) heats up the surrounding reservoir to

temperature T

2

. The change in heat per unit mass

is Δq

2

= h

2

– h

3

.

Controlled expansion:

The condensed refrigerant reaches the expansion

valve where it is allowed to expand to a lower

pressure without any mechanical work being done.

This results in a drop in temperature since work

needs to be done against the force of attraction

between refrigerant molecules (Joule-Thomson

effect). Enthalpy remains constant (h

4

= h

3

).

Vaporisation:

In the evaporator, the refrigerant absorbs heat and

vaporises completely. This causes the surrounding

reservoir to cool to a temperature T

1

. The heat

absorbed per unit mass is Δq

1

= h

1

– h

4

.

The vaporised refrigerant is sucked back in

again by the compressor to start the compres-

sion process anew.

8. Example experiments

8.1

Efficiency of the compressor

The efficiency of the compressor η

co

is given by

the ratio of the change in energy ΔQ

2

provided

to the warm water reservoir per unit time Δt, to

the power P supplied to the compressor to per-

form its work. It decreases as the temperature

difference between the condenser and the

evaporator increases.

t

P

T

m

c

t

P

Q

Δ

⋅

Δ

⋅

⋅

=

Δ

⋅

Δ

=

2

2

co

η

c

= specific heat capacity of water and

m

= mass of water.

Determining the efficiency:

•

Connect the heat pump to the mains supply.

•

Fill up the water containers with 2000 ml

water and mount them into the retaining

plates.

•

Allow the compressor to run for about 10

minutes before starting the experiment until

it reaches its operating temperature.

•

Then fill up the water containers again and

mount the two thermometers into the hold-

ers at the water containers.

•

Stir the water in the containers thoroughly

throughout the experiment.

•

Determine and note the initial temperature in

both water containers.

•

Push the button „Zeit“ (time) at the energy

monitor 2x and at the same time switch

•

Read off the power consumed so far and the

temperatures in the two water reservoirs at

regular intervals and make a note of them.