Ironwood Electronics Gull Wing Surface Mount Foot Soldering Instructions User Manual

Page 3

Page 3 of 4

GSI.doc, Rev. C

Gull wing Surface mount Foot Soldering Instructions (continued)

Tel: (800) 404-0204

www.ironwoodelectronics.com

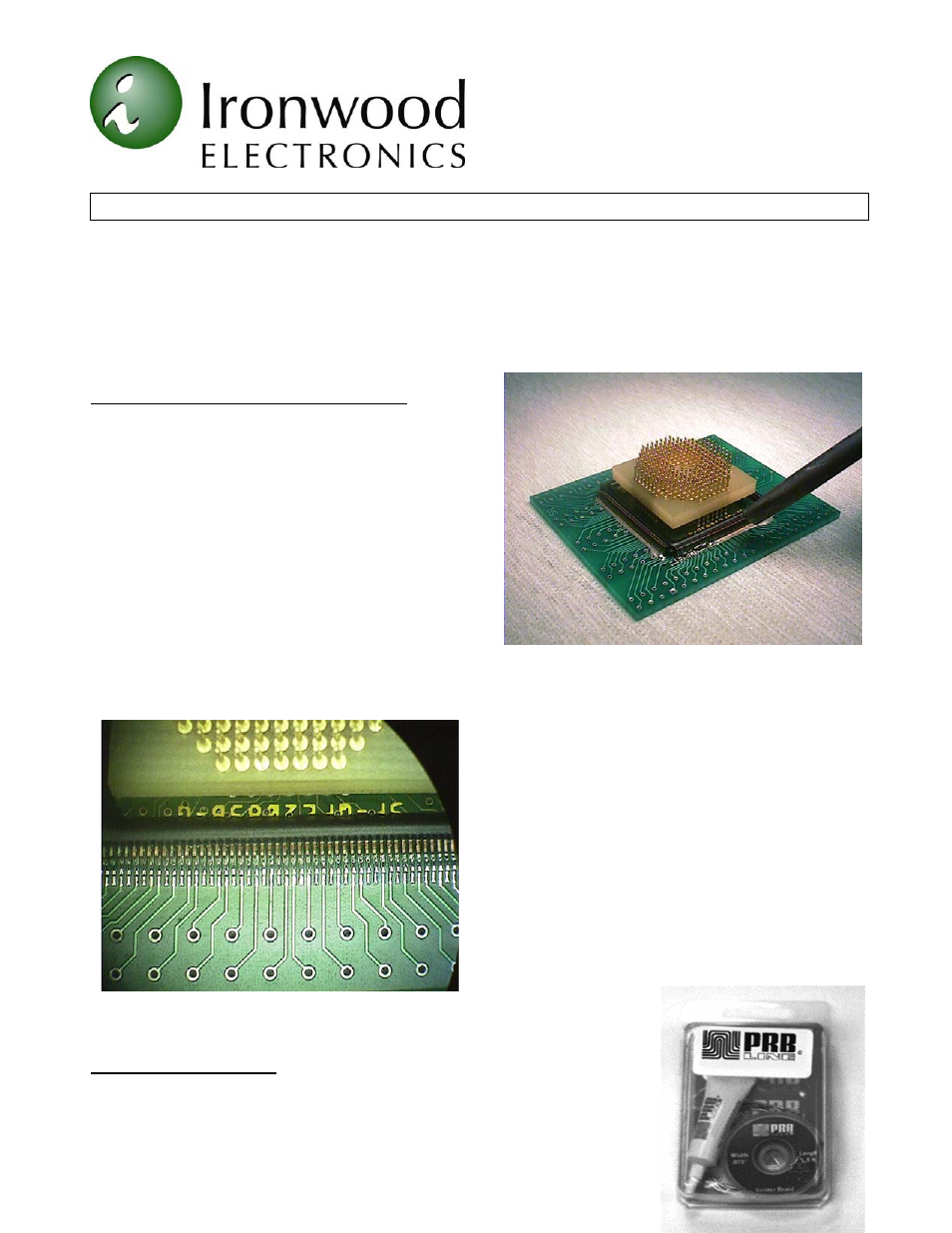

(e) Reflow, with a hot air wand/gun, the solder over a few of the pads in opposite corners (diagonally) of the land

pattern (Figure 6).

(f) Check the foot alignment.

(g) Continue by reflowing the remaining solder paste. Add or remove solder as needed (see step (f) in method

1.).

SOLDERING IRON - Soldering method #3

This method has produced very good results but may be

more time consuming than the other two methods.

Caution must be used when touching the soldering iron

tip to the emulator foot. Excessive heat or pressure may

damage the pads on the side of the foot.

(a) Using a small diameter solder wire (approx. 0.015" or

smaller) and a very fine tipped soldering iron, add enough

solder to two opposite corner (diagonal) pads to cover

them.

(b) Align and place the emulator foot over the QFP land

pattern (see steps (c) and (d) in method 1).

(c) Holding the foot in place, by pressing down gently on

the gold terminal pins, place the iron tip on the two pads

to reflow the solder. This will tack and keep the foot in

alignment.

(d) Under a microscope or magnifying lens, if available, solder the remaining edge pads of the foot to the target

PCB land pattern using a liberal amount of solder (shorts

between adjacent pads can be removed later).

(e) Apply a generous amount of flux along the side of the

foot.

(f) Tilt the PCB and emulator foot at 30 - 45 degree

angle. Start at one corner and pull the tip of the iron

along the side of the foot to remove excess solder

deposits. Clean the tip of the iron often. Repeat this step

several times starting at a point on the foot ahead of the

excess solder. Continue along the side of the foot until

shorts are removed and a fillet is present between feet

and target PCB pads.

(g) Repeat steps (e) and (f) for the remaining three sides.

The finished solder connections are shown in Figure 7.

Removing or Desoldering

Conventional methods can be used to remove a surface mount foot from your

target board, however we recommend the use of PRB Line® D’SOLDER™.;

This SMT device removal product avoids the use of excessive heat that can

compromise the integrity of our product and your target board. The specially

Figure 6: Reflow using hot air tool

Figure 7: Finished Solder Fillets