Page 2 of 4 – Ironwood Electronics GHz socket Assembly Instructions User Manual

Page 2

Page 2 of 4

GFI.doc, Rev.A, Created by E Smolentseva, 10/22/03

Tel: (800) 404-0204

www.ironwoodelectronics.com

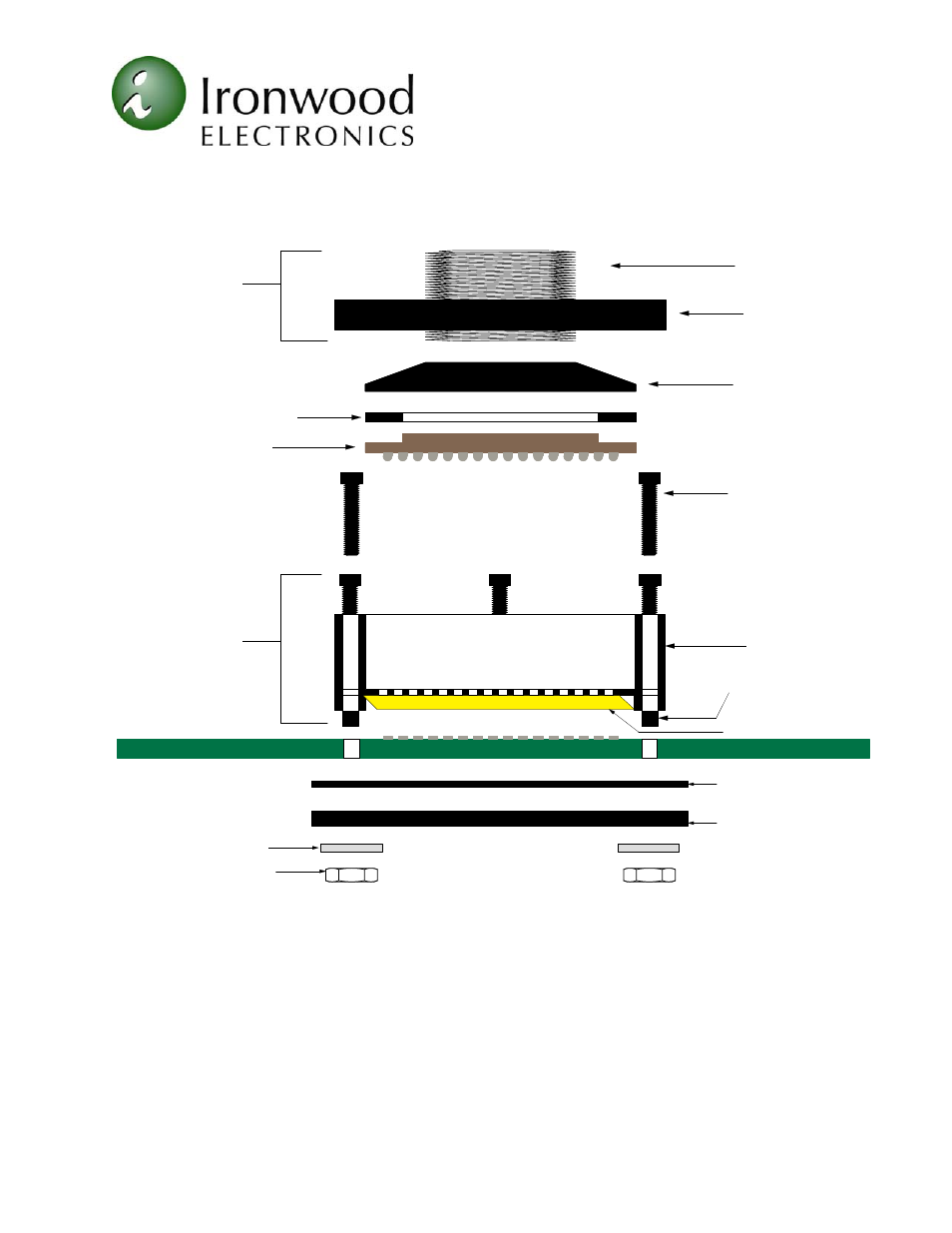

Socket Base

Target PCB with SMT pads

Socket

Top Assembly

Compression Screw

Compression plate

BGA Package

Angle wire elastomer

Socket Lid

Round head Screw

Dowel pin

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

Socket Base Assembly

Backing Plate

(not necessary for

some sockets)

Hex Nut

Nylon Washer

IC Frame

Insulation Plate

(not necessary for

some sockets)

Figure 1: Graphical Illustration of Socket Assembly

Torque tool:

A torque tool should be used to apply the proper torque to the compression screw. There are

adjustable and factory preset torque tools currently available, which may be purchased

separately.

• TL-TORQUEDRIVER-01 (adjustable, 1.25-6.25 inch lb range)

• TL-TORQUEDRIVER-02 (adjustable, 3-15 inch lb range)