2 lubrication – R&M Materials Handling ELECTRIC CHAIN HOISTS LoadMate Chain Hoist LM 16-20-25 User Manual

Page 51

LM16-20-25 I&M MANUAL/EN/11.30.2010

51/73

This document and the information contained herein, is the exclusive property of R&M Materials Handling, Inc., and represents a non-public, confidential and proprietary trade secret that

may not be reproduced, disclosed to third parties, altered or otherwise employed in any manner whatsoever without the express written consent of R&M Materials Handling, Inc.

Copyright © (2010) R&M Materials Handling, Inc. All rights reserved.

7.2

Lubrication

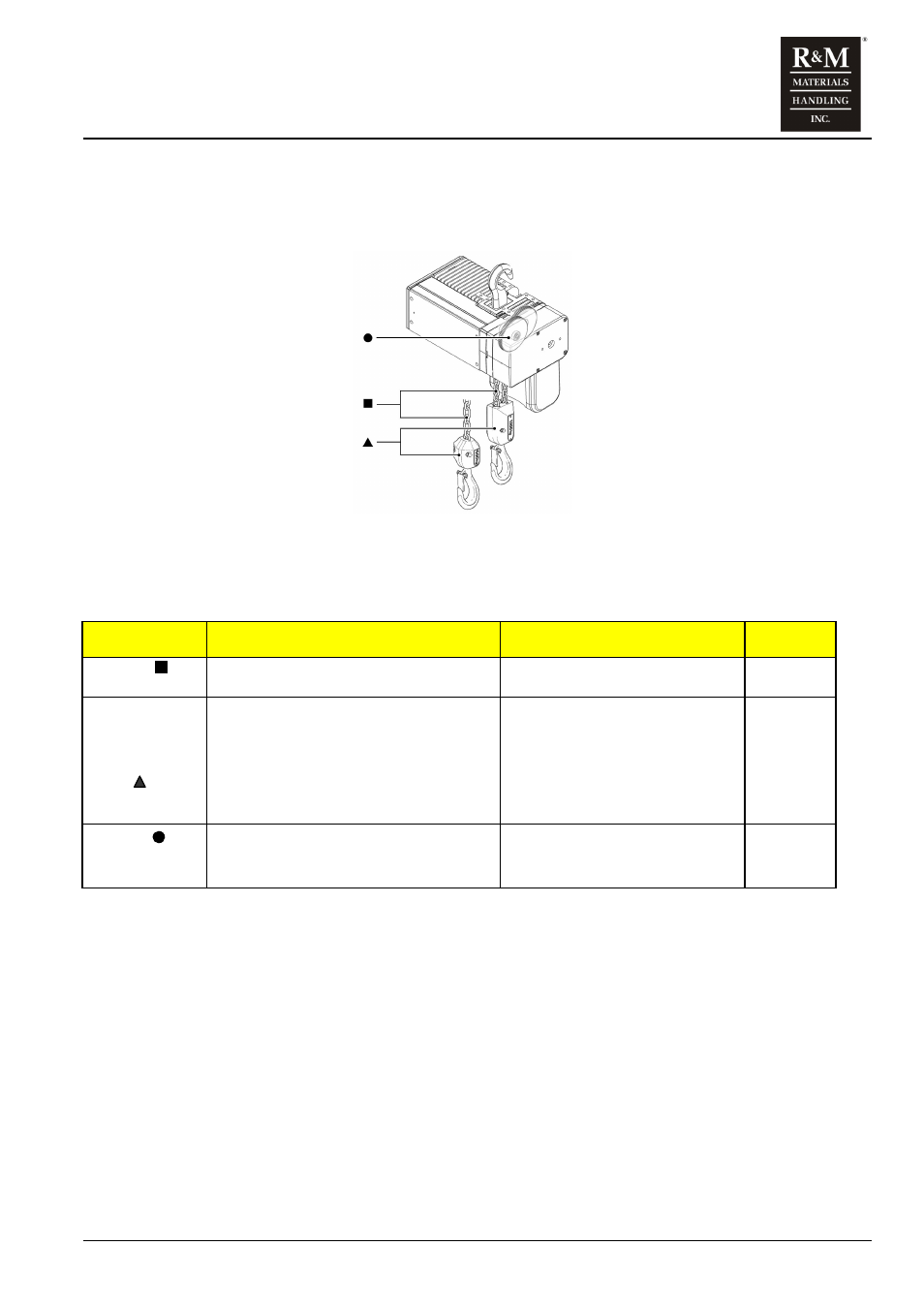

Table 8. Lubrication Specifications

LUBRICATION

POINT

SPECIFICATIONS

ACCEPTABLE LUBRICANTS

QUANTITY

Chain

Oil or Liquid grease

Chain lubricating fluid (Ceplattyn

or similar) EP-90

As required

Idler sprocket

Slide bearing +

bearing

Grease (without MoS2)

KP 2 (DIN 51 502)

Soap-based lithium

Approx. drip point + 500°F

Worked penetration 509-563°F

Operating temperature - 4°F - +266°F

BP: BP Energrease LS - EP 2

Esso: Unirex N2

Mobil: Mobilgrease HP

Shell: Shell Alvanio EP Grease 2

As required

Gears

Oil EP220

Mobil: L-CKC220

BP: Energol XP220

Shell: Omala 150/220

1.6 liters

1 ¾ qts

Open Wheel Gearing: EP1 Mobilux or equivalent.