3 safety instructions for servicing, 3 ges drive – R&M Materials Handling END TRUCKS BRIDGE DRIVES WHEEL BLOCKS GES Drive Manual User Manual

Page 4

R&M Materials Handling, Inc.

4501 Gateway Boulevard

Springfield, Ohio 45502

%

: (937) 328-5100

FAX: (937) 325-5319

4/11

R&M Materials Handling, Inc. reserves the right to alter or amend the above information without notice.

•

If defects have been noticed in the drive, carry out the necessary inspections and repair work. Be

sure that the drive operates properly before you start to use it again.

•

Avoid short, jerky motions. Unnecessary short starts will cause the motor to overheat quickly.

•

Do not change the size of the fuses provided in the controls. A qualified electrician should carry out all

electrical work.

2.3 Safety instructions for servicing the drive

I

Follow these instructions when servicing the drive:

•

Carry out regular inspections and preventive maintenance in compliance with the instructions. Keep a

record of inspections and servicing. Regular servicing and inspection procedures are necessary for

the safe and efficient operation of the drive. In uncertain or unusual cases, contact the supplier of the

drive.

•

Pay special attention to the operation of the brake. It is essential that safety devices work correctly

and are in full operating order.

•

Use trained service personnel for servicing the drive. The person servicing the drive must be

competent for the task and must be familiar with the servicing and inspection instructions.

•

Use only genuine spare parts approved by the manufacturer of the drive.

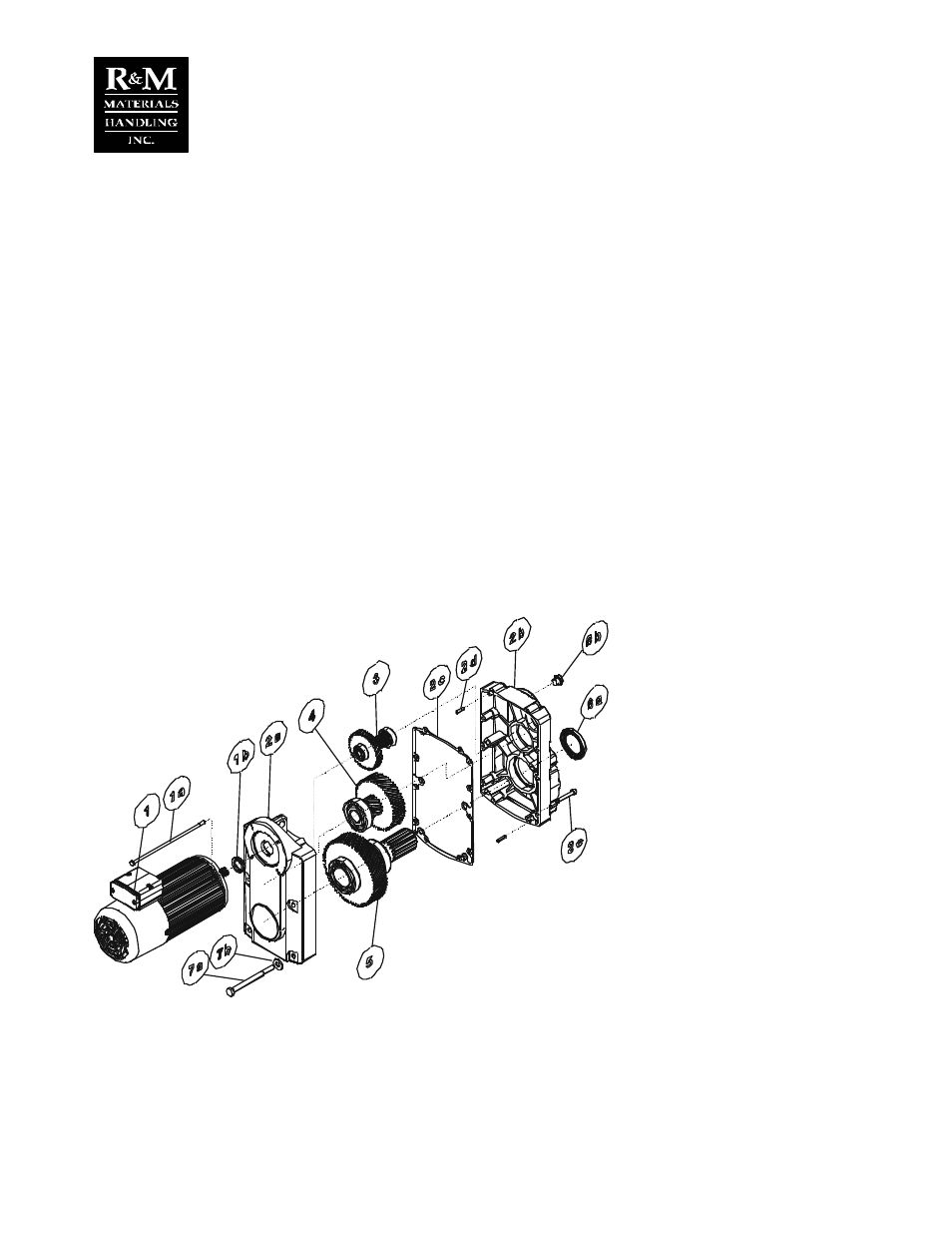

3 GES Drive

1 Motor with drive pinion

1a Motor mounting bolt

1b Motor shaft seal

2a Gear cover

2b Gear housing

2c Gasket

2d Aligning pins

2e Gear mounting bolts

3 First intermediate shaft set

(gear shaft, wheel and

bearings)

4 Second intermediate shaft

set

5 Secondary shaft set

6a Secondary shaft sealing

6b Breather plug

7a Mounting bolt

7b Washer