Prokit's Industries GS-23K User Manual

Instruction manual, Gs-23k gas soldering iron kit – auto ignition

GS-23K Gas Soldering Iron Kit – Auto Ignition.

Instruction Manual

Thanks for buying PRO’SKIT GS-23K Gas Soldering Iron Kit –

Auto Ignition. Please read all instructions carefully before using

the product.

SPECIFICATIONS

Iron size

Φ29 x 245mm

Gas container capacity

15ml

Operating time

About 90mins

(one gas filling)

Soldering temperature

up to 500℃

Hot Blow temperature

up to 600℃

Torch temperature

up to 1300℃

APPLICATIONS

Repair switch board, meters

TV Cable system

Soldering circuit board

Loosen rusted nut and bolts

Sensitive IC board

Jewelry

repair

Silver

solder

Weld

plastics

Automotive

/

Aviation service repairs

WARNING

1.) Keep the touch out of reach of children.

2.) Read directions carefully before use.

3.) The burn tip and other accessory tips get hot in operation.

Do not touch the tip or accessories, or place them on

flammable objects

4.) Always have a fire extinguisher or bucket of water near

the torch work area.

5.) Always point away from eyes and body when igniting or

operating. Flam is invisibles sunlight; it can cause injury if

used with extreme.

6.) Under no circumstances should you attempt to repair a

damage torch

7.) Do not store under direct sunlight or anywhere that will

exceed 104℉ / 40℃

8.) Do not immerse in water.

9.) Make sure the adjustment knob is firmly closed and the

flame is completely extinguished after using.

10.) Use only in well ventilated areas.

OPERATION

Fig1

IGNITION

1.)

Make sure the exhaust vent is facing upward to

avoid the damage of tabletop.

2.) Press

the

safety lock button

and

simultaneously using your thumb to pull down the

trigger. This action will ignite the soldering iron.

3.) Hold

the

ignition button

and release the

safety lock button

. Slide the continuous flame

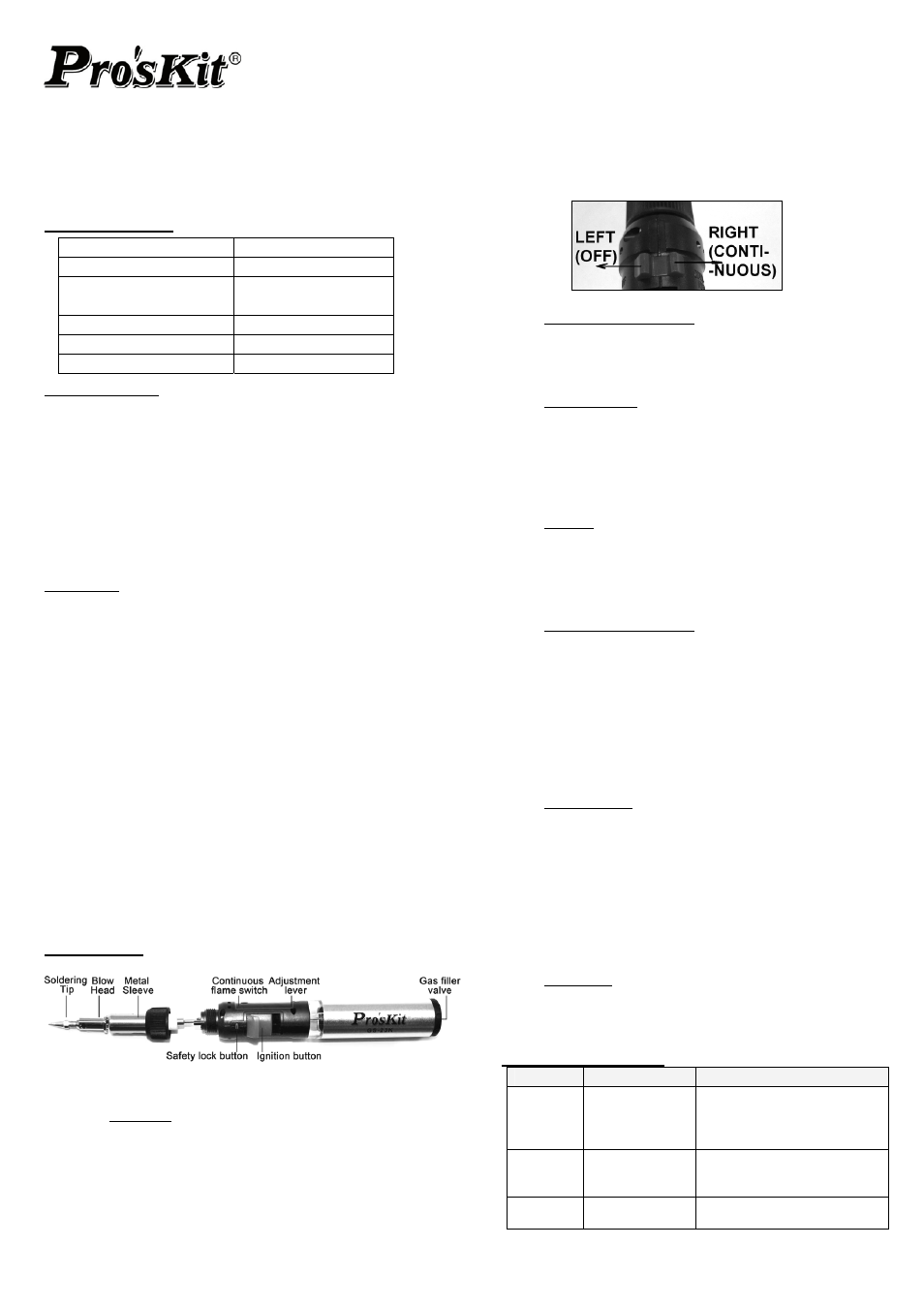

switch

to right (Fig2) for a constant flame.

Fig2

EXTINGUISHING (Fig2)

Slide the continuous flame Switch to left (OFF), and

this will cut off the gas supply and extinguish the

flame.

HOT BLOWER

Disassemble the soldering tip by rotating the tip

counterclockwise. The assembly will now be used as

hot blower without the soldering tip. Operation will be

the same as above for the soldering iron.

(fig1.)

TORCH

Disassemble the soldering tip and hot blow head

with metal sleeve by rotating counterclockwise. Install

the metal sleeve back to the unit. Operation will be the

same as above for the soldering iron. (Fig2)

FLAME ADJUSTMENT

Slide the adjustment lever toward right side to

increase the flame strength or toward left to decrease

the flame strength.

When the flame is at “+” position, the longer flames

may cause the torch to flare or extinguish. In this

situation, please move the gas adjustment lever to “-”

side for decreasing the flame strength and set up a

most efficient flame(Blue Flame).

GAS REFUEL

1.) Use only high quality butane gas.

2.) Before refilling make sure that the continuous

flame Switch

at left (OFF)side. (Fig2)

3.) Follow the directions on butane fuel can. Insert the

tip to filler valve, using a pumping action for best

results

4.) After filling allow the gas to stabilize a few minutes

before ignite.

STORAGE

Make sure that the torch is turned off and cool, before

storing or leaving unstable.

TROUBLE SHOOTING

Problem

Probable cause

Solution

Does not

ignite

1. Empty fuel

2. Gas Pressure

too high or too

low.

1. Refuel

2.

Slide the adjustment lever

toward right or left.

Excessive

gas flow

Setting too high

Adjust gas regulator gradually

Re-ignite the torch by gradually

increasing the gas.

Low gas

pressure

1. Low

fuel

2. Cold

fuel

1. Refuel

2.

Hold in hands to warm up.