Rainbow Electronics MAX5095A User Manual

Page 13

V

CC

and Startup

In normal operation, V

CC

is derived from a tertiary wind-

ing of the transformer. However, at startup there is no

energy delivered through the transformer, thus a resistor

must be connected from V

CC

to the input power source

(see R

ST

and C

ST

in Figures 5 to 8). During startup, C

ST

charges up through R

ST

. The 5V reference generator,

comparator, error amplifier, oscillator, and drive circuit

remain off during UVLO to reduce startup current below

65µA. When V

CC

reaches the undervoltage-lockout

threshold of 8.4V, the output driver begins to switch and

the tertiary winding supplies power to V

CC

. V

CC

has an

internal 26.5V current-limited clamp at its input to protect

the device from overvoltage during startup.

Size the startup resistor, R

ST

, to supply both the maxi-

mum startup bias (I

START

) of the device (65µA max)

and the charging current for C

ST

. The startup capacitor

C

ST

must charge to 8.4V within the desired time period

t

ST

(for example, 500ms). The size of the startup

capacitor depends on:

1) IC operating supply current at a programmed oscilla-

tor frequency (f

OSC

).

2) The time required for the bias voltage, derived from

a bias winding, to go from 0 to 9V.

3) The MOSFET total gate charge.

4) The operating frequency of the converter (f

SW

).

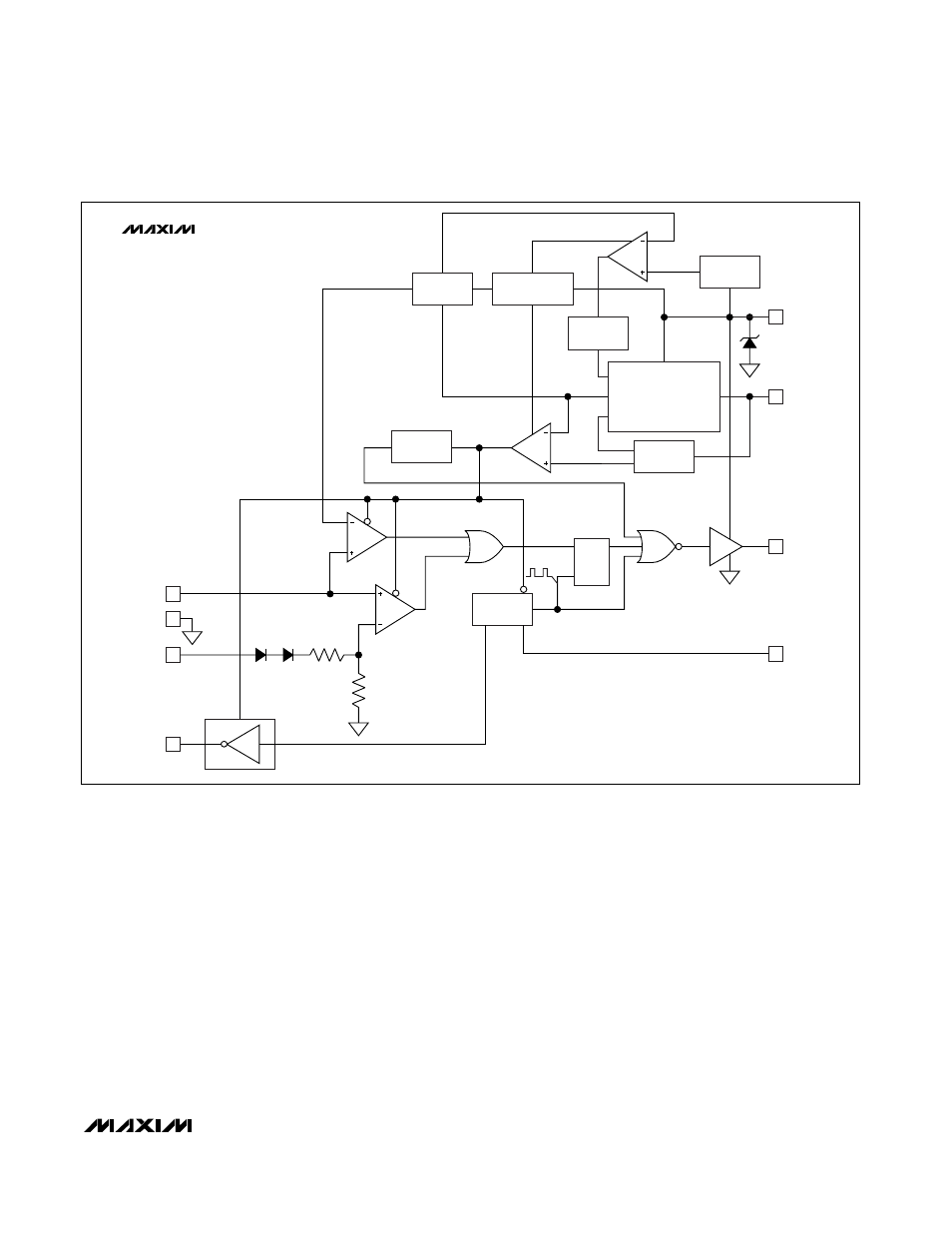

MAX5094A/B/C/D/MAX5095A/B/C

High-Performance, Single-Ended, Current-Mode

PWM Controllers

______________________________________________________________________________________

13

UVLO

REFERENCE

2.5V

PREREGULATOR

5V

VOLTAGE-

DIVIDER

THERMAL

SHUTDOWN

EN-REF

BG

SNS

V

DD

5V REGULATOR

VOLTAGE-

DIVIDER

8

7

26.5V

V

CC

REF

2.5V

VP

REG_OK

DELAY

S

R

Q

OSC

Q

4 R

T

/C

T

6 OUT

ILIM

CPWM

0.3V

EN-DRV-BAR

R

2R

3

5

1

2

CS

GND

COMP

ADV_CLK

CLK

MAX5095C

VP

2.5V

50% MAX DUTY CYCLE

8.4V/7.6V

Figure 3. MAX5095C Functional Diagram